Process for coating lithium ion battery with slurry

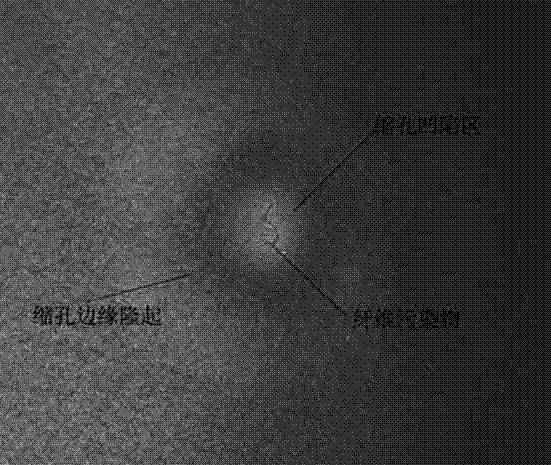

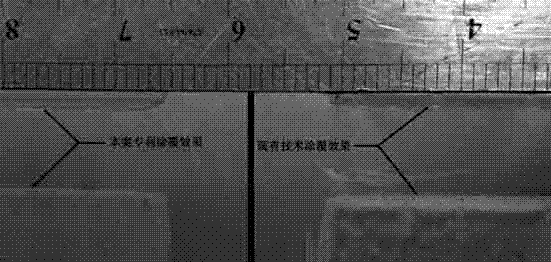

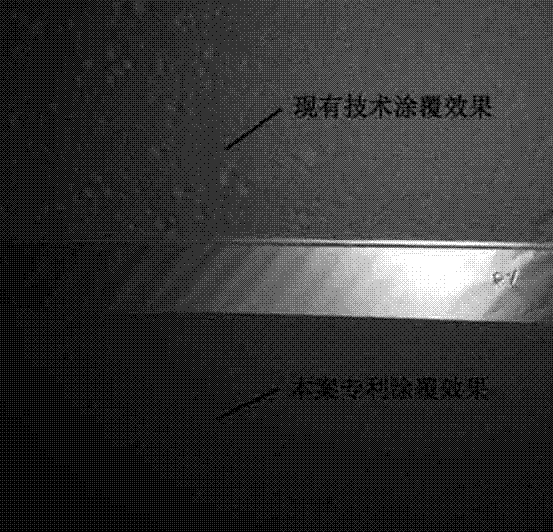

A lithium-ion battery, coating technology, applied in battery electrodes, secondary batteries, electrode current collector coatings, etc. Hole or shrinkage phenomenon, consistent color and smooth edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, water system negative electrode slurry:

[0050] 1. Add 120 kg of pure water, 1 kg of conductive carbon black, 95 kg of artificial graphite, and 1.5 kg of CMC, and stir at a medium speed for 2 hours until the slurry is evenly dispersed and the color is consistent;

[0051] 2. Add 0.1 kg of polyether modified silicone oil, and stir at medium speed for 30 minutes;

[0052] 3. Add 5kg of SBR emulsion (including 2.5kg of solid content), and stir at a medium speed for 30 minutes;

[0053] 4. Add 0.2 kg of polyether trisiloxane, and stir at medium speed for 30 minutes;

[0054] 5. Test viscosity, about 3500mPa·s, if the viscosity is too high, you can add appropriate amount of water to adjust;

[0055] 6. Vacuum stirring for 30 minutes to remove tiny air bubbles in the slurry, while adjusting the temperature of the slurry to be close to room temperature;

[0056] 7. The slurry passes through a 120-mesh single-layer stainless steel screen, and is transferred to...

Embodiment 2

[0058] Embodiment 2, water-based positive electrode slurry:

[0059] 1. Add 120kg of pure water, 1kg of conductive carbon black, 120 kg of lithium cobaltate, and 1.6kg of CMC, and stir at a medium speed for 2 hours until the slurry is evenly dispersed and the color is consistent;

[0060] 2. Add 0.1 kg of polyether modified silicone oil, and stir at medium speed for 30 minutes;

[0061] 3. Add 5kg of SBR emulsion (including 2.5kg of solid content), and stir at a medium speed for 30 minutes;

[0062] 4. Add 0.2 kg of polyether trisiloxane, and stir at medium speed for 30 minutes;

[0063] 5. Test viscosity, about 3500mPa•s, if the viscosity is too high, you can add appropriate amount of water to adjust;

[0064] 6. Vacuum stirring for 30 minutes to remove tiny air bubbles in the slurry, while adjusting the temperature of the slurry to be close to room temperature;

[0065] 7. The slurry passes through a 120-mesh single-layer stainless steel screen, and is transferred to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com