Coating end milling cutter for graphite die machining and preparation method of coating end milling cutter

A technology for graphite molds and end mills, which is applied in metal processing equipment, milling cutters, milling machine equipment, etc., can solve the problems of diamond film coating thickness and graphite processing surface roughness, etc., so as to improve processing efficiency and processing surface Quality, improved surface finish, long working life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

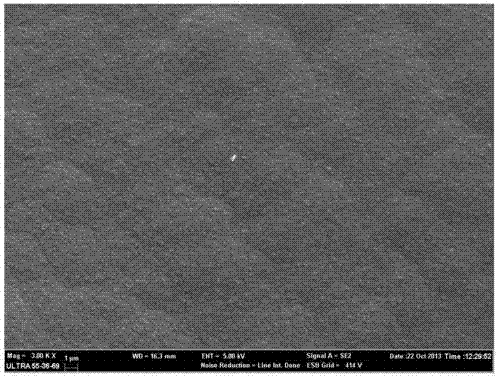

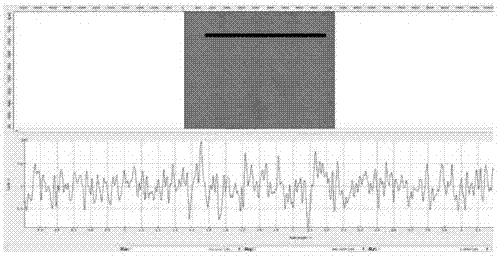

[0042] The schematic diagram of the appearance of the coated end mill used in this embodiment is as follows figure 1 and figure 2 and image 3As shown, the diameter a is 6mm, the total length e is 50mm, the length of the cutting part is 8mm, the length of the three short bottom edges is 2mm, and the length of one long bottom edge is 2.82mm, and the long bottom edge passes through the bottom surface of the end mill. At the center of the circle, the remaining three short bottom edges do not pass through the center of the bottom surface of the end mill. The width of the flute between the long and short bottom edges is 1.3mm, the rake angle of the bottom edge is 5°, and the rear angle of the bottom edge is 7° , with a helix angle of 25°. The base material of the tool is cemented carbide with a cobalt content of 6%, and the particle size of the tungsten carbide is 1 micron.

[0043] Put the end mill sharpened by the five-axis CNC grinder in a vertical rotary tool passivation de...

Embodiment 2

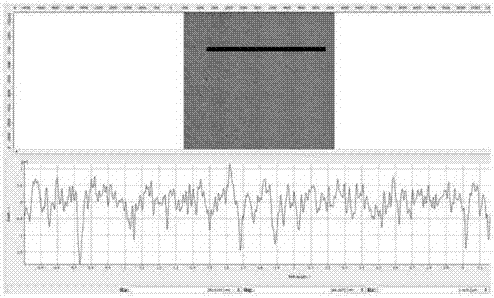

[0054] The diameter of the coated end mill used in this embodiment is 8mm, the length f of the cutting part is 8mm, and it has three short and one long bottom edges, the length of the long bottom edge is 4.1mm, and the length of the three short bottom edges is 2.48mm, of which The long bottom edge passes through the center of the bottom surface of the end mill, and the other three short bottom edges do not pass through the center of the bottom surface of the end mill. The width of the flute between the long bottom edge and the short bottom edge is 1.36mm; the rake angle of the bottom edge is 7°, the bottom edge relief angle is 12°, and the helix angle is 45°. After the end mill with a diameter of 8 mm is passivated, the radius of the cutting edge of the bottom edge is 20 μm.

[0055] Soak the cemented carbide substrate in the Murakami solution for 30 minutes of ultrasonic cleaning, which breaks the tungsten carbide (WC) particles on the surface of the cemented carbide and caus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com