Method of adjusting expanding property of black cotton soil

A technology of black cotton soil and expansiveness, which is applied in the field of adjusting the expansiveness of black cotton soil, and can solve the problems of failing to meet engineering mechanics standards and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

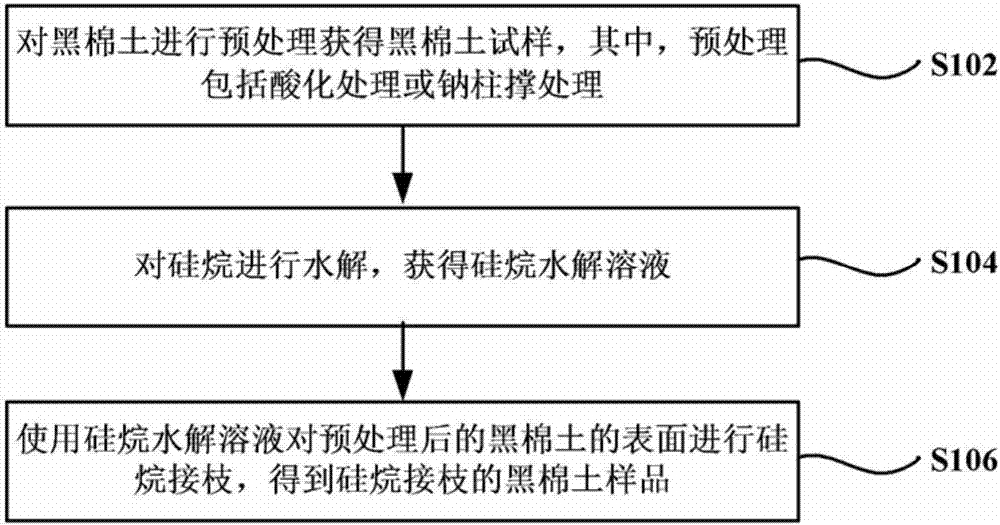

Method used

Image

Examples

Embodiment 1

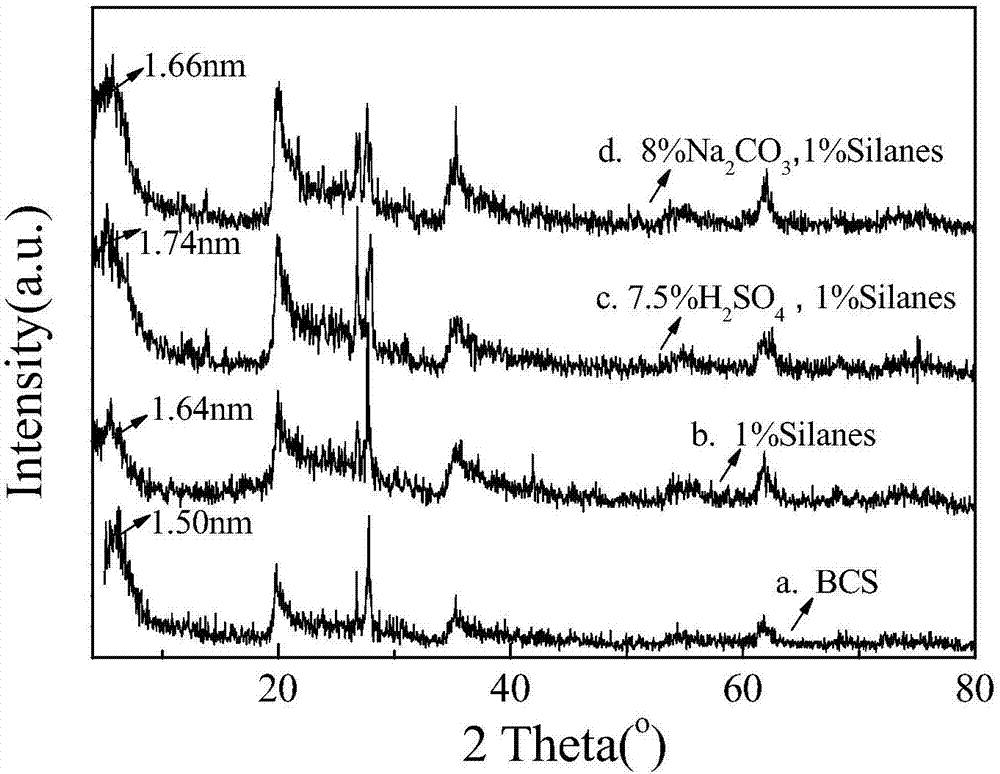

[0065] The original black cotton soil is directly grafted with silane

[0066] 1. Hydrolysis of silane: Add silane coupling agent with a volume fraction of 0.5% to 100mL of ethanol / water (9:1 by volume) mixed solution, adjust the pH value between 4-5 with glacial acetic acid, To promote hydrolysis, stir magnetically at room temperature for 1 hour.

[0067] 2. Surface grafting of black cotton soil: Disperse 15g of black cotton soil in a mixed solution of 100ml ethanol / water (9:1 by volume), put it in a beaker and stir until it is evenly dispersed to form a stable suspension. The silane solution was slowly dropped into the suspension. 70°C water bath for 4 hours. After the reaction, filter with suction, wash until neutral, and dry in an oven at 80°C for 12 hours; grind in a mortar for later use, and obtain a black cotton soil sample grafted with silane.

[0068] The measured free expansion rate is 120%.

Embodiment 2

[0070] The original black cotton soil is directly grafted with silane

[0071] 1. Hydrolysis of silane: Add 1% silane coupling agent by volume fraction to the mixed solution of 100mL ethanol / water (9:1 by volume), and adjust the pH value between 4-5 with glacial acetic acid to promote Hydrolyze, and magnetically stir for 1 hour at room temperature.

[0072] 2. Surface grafting of black cotton soil: Disperse 15g of black cotton soil in a mixed solution of 100mL ethanol / water (9:1 by volume), put it in a beaker and stir it magnetically, and wait until it is evenly dispersed to form a stable suspension. Slowly drop the silane solution into the suspension, and put it in a water bath at 70°C for 4 hours; after the reaction, filter it with suction, wash until it is neutral, dry it in an oven at 80°C for 12 hours, and grind it finely in a mortar for later use to obtain silane-grafted black cotton soil sample.

[0073] The free expansion rate was determined to be 61%.

Embodiment 3

[0075] The original black cotton soil is directly grafted with silane

[0076] 1. The hydrolysis of silane: the silane coupling agent that volume fraction is 2% is added in the mixed solution of 100mL ethanol / water (volume ratio is 9:1), adjust pH value between 4-5 with glacial acetic acid, promote Hydrolyze, and magnetically stir for 1 hour at room temperature.

[0077] 2. Surface grafting of black cotton soil: Disperse 15g of black cotton soil in a mixed solution of 100mL ethanol / water (9:1 by volume), put it in a beaker and stir it magnetically, and wait until it is evenly dispersed to form a stable suspension. Slowly drop the silane solution into the suspension, and put it in a water bath at 70°C for 4 hours; after the reaction, filter it with suction, wash until it is neutral, dry it in an oven at 80°C for 12 hours, and grind it finely in a mortar for later use to obtain silane-grafted black cotton soil sample.

[0078] The measured free expansion rate was 41%.

[0079...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com