Lithium titanate composite electrode plate and preparation method thereof, and lithium battery

A lithium titanate and pole piece technology, which is applied in the field of lithium ion battery preparation, to achieve the effects of improving efficiency, improving pass rate, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

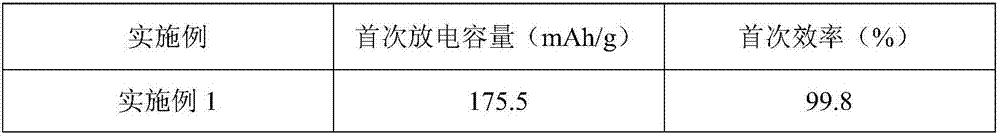

Embodiment 1

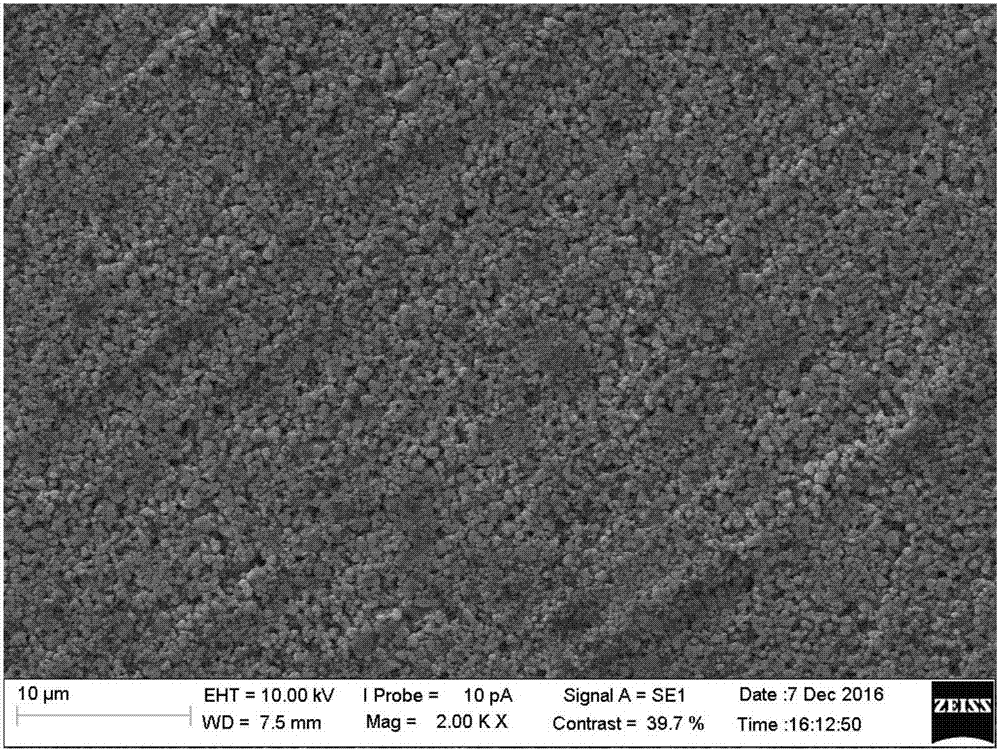

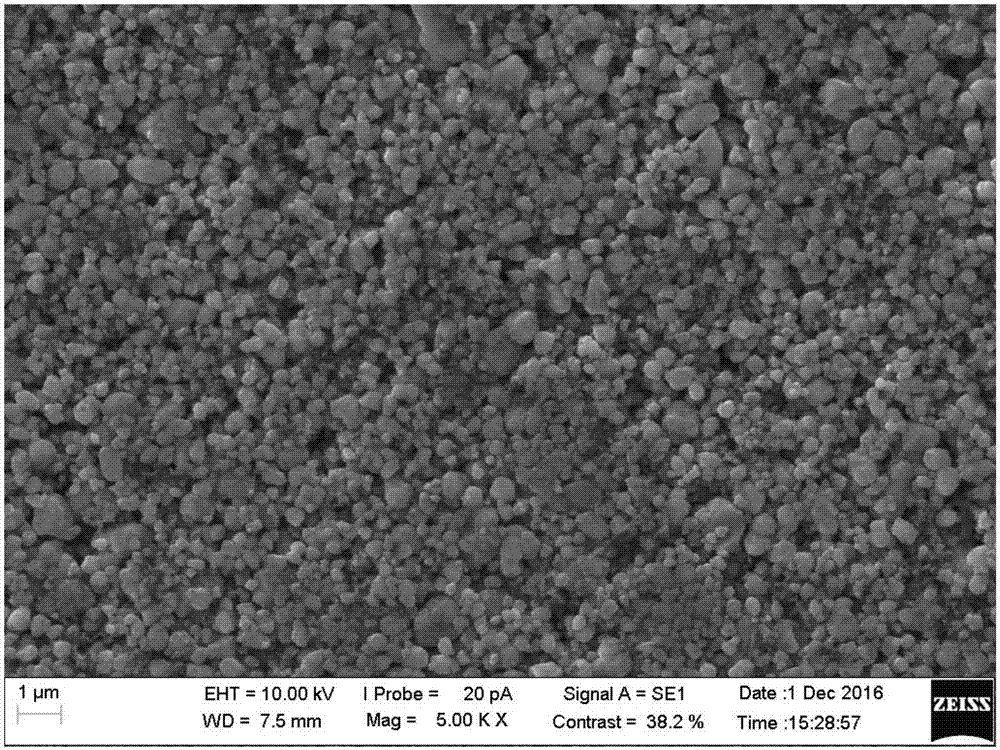

[0038] The lithium titanate composite pole piece of this embodiment includes a current collector and an inner layer, an intermediate layer, and an outer layer arranged on the surface of the current collector; the inner layer is a lithium titanate layer; the middle layer is a lithium silicate layer; the outer layer is an organic Lithium layer; the thickness of the middle layer is 500nm; the thickness of the outer layer is 3 μm; the thickness of the inner layer is 50 μm; the lithium titanate layer is composed of lithium titanate, super carbon black, polyvinylidene fluoride, lithium titanate, super The mass ratio of carbon black and polyvinylidene fluoride is 92:2:6; the organic lithium layer is composed of ethyl lithium, SP conductive agent, binder polyvinylidene fluoride, and the ethyl lithium, SP, polyvinylidene fluoride The mass ratio of vinyl fluoride is 80:17:4.

[0039] The preparation method of the lithium titanate composite pole piece of the present embodiment comprises ...

Embodiment 2

[0045] The lithium titanate composite pole piece of this embodiment includes a current collector and an inner layer, an intermediate layer, and an outer layer arranged on the surface of the current collector; the inner layer is a lithium titanate layer; the middle layer is a lithium sulfate layer; the outer layer is an organic lithium layer; the thickness of the middle layer is 100nm; the thickness of the outer layer is 1 μm; the thickness of the inner layer is 100 μm; the lithium titanate layer is composed of lithium titanate, super carbon black, polyvinylidene fluoride, lithium titanate, super carbon The mass ratio of black and polyvinylidene fluoride is 90:3:7; the organic lithium layer is composed of propyllithium, SP conductive agent, polyvinylidene fluoride, and the mass ratio of propyllithium, SP, polyvinylidene fluoride The ratio is 60:29:3.

[0046] The preparation method of the lithium titanate composite pole piece of the present embodiment comprises the following st...

Embodiment 3

[0052] The lithium titanate composite pole piece of this embodiment includes a current collector and an inner layer, an intermediate layer, and an outer layer arranged on the surface of the current collector; the inner layer is a lithium titanate layer; the middle layer is a lithium sulfate layer; the outer layer is an organic lithium layer; the thickness of the middle layer is 500nm; the thickness of the outer layer is 5 μm; the thickness of the inner layer is 300 μm; the lithium titanate layer is composed of lithium titanate, super carbon black, polyvinylidene fluoride, lithium titanate, super carbon The mass ratio of black and polyvinylidene fluoride is 95:2:3; the organic lithium layer is made up of phenyllithium, graphene, polyvinylidene fluoride, and the mass ratio of said phenyllithium, graphene, polyvinylidene fluoride The ratio is 90:5:5.

[0053] The preparation method of the lithium titanate composite pole piece of the present embodiment comprises the following step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com