Lithium titanate electrode material with core-shell structure, preparation method and application

An electrode material, core-shell structure technology, applied in the field of lithium ion battery materials and battery preparation, can solve the problems of slow lithium ion intercalation, poor battery rate performance, etc., to improve lithium ion transmission rate, reduce expansion rate, The effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

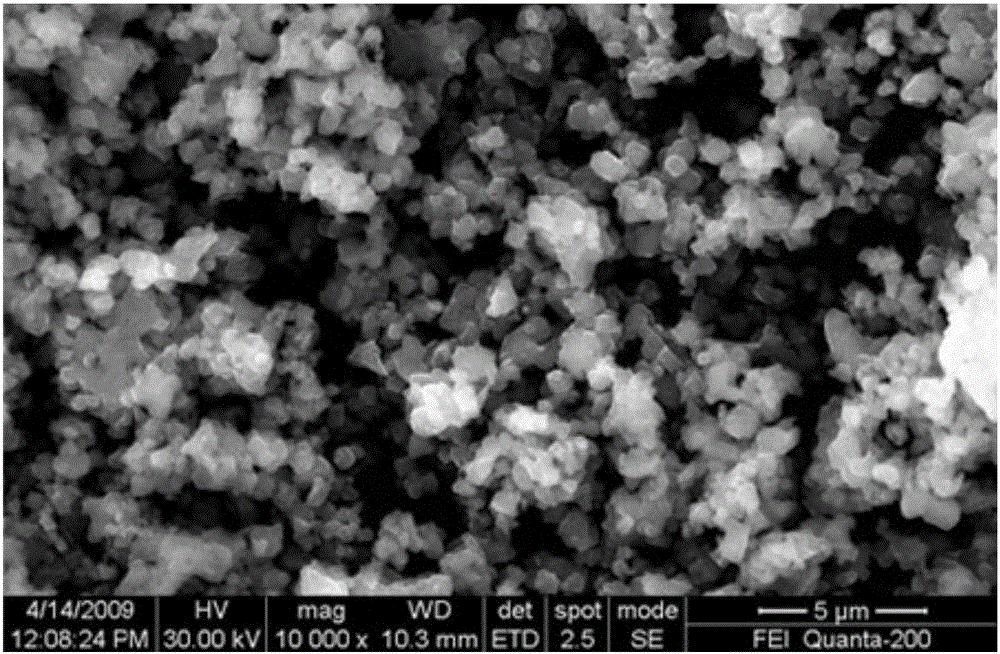

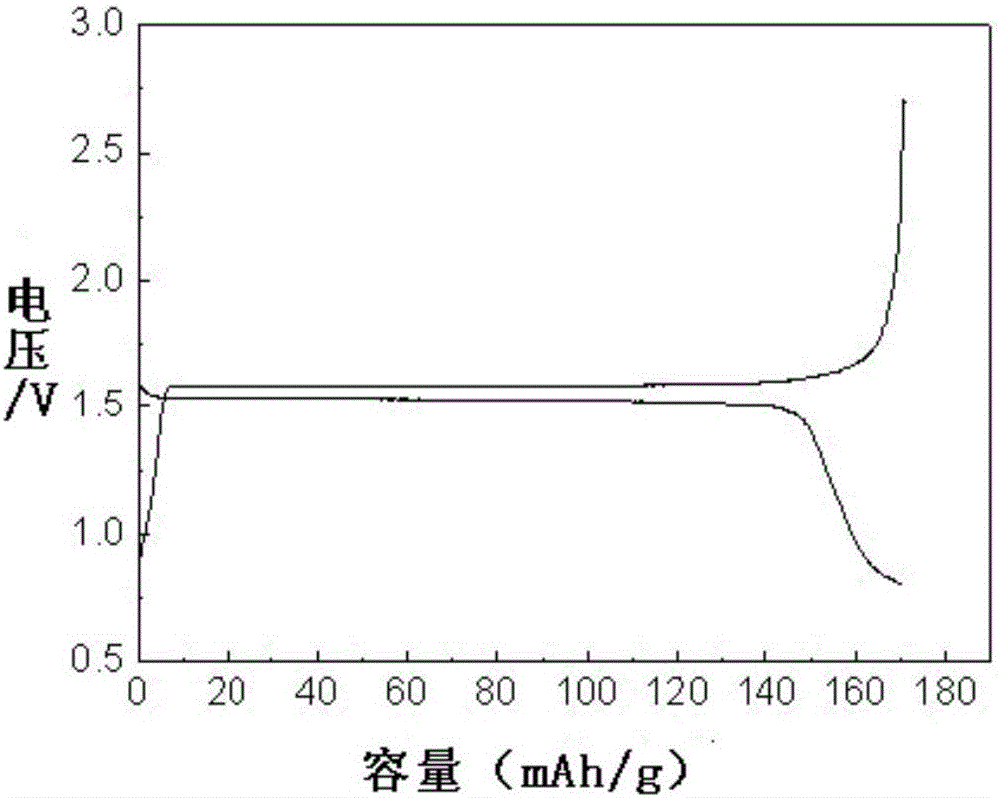

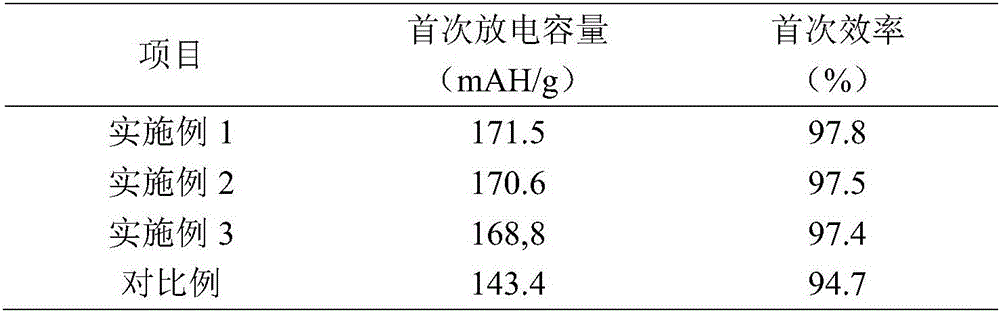

[0029] Lithium titanate electrode material with core-shell structure, the inner core is lithium titanate, along the inner core, there are intermediate carbon layer and lithium metaaluminate composite layer in sequence, and the intermediate carbon layer and lithium metaaluminate composite layer constitute the outer shell of the material . Wherein, the size of the inner core is 500nm, the thickness of the middle carbon layer is 30nm, and the thickness of the lithium metaaluminate composite layer is 30nm.

[0030] The preparation steps of lithium titanate electrode material are:

[0031] 1) Preparation of the raw material mixture for the intermediate carbon layer and the raw material mixture for the lithium metaaluminate composite layer:

[0032] Mix 100g of glucose, 2g of polyethylene glycol, 2g of carbon nanotubes and 1000mL of formic acid evenly to obtain the mixed solution A, which is the mixed solution of the intermediate carbon layer raw materials;

[0033] Mix 100g of li...

Embodiment 2

[0039] Lithium titanate electrode material with core-shell structure, the inner core is lithium titanate, along the inner core, there are intermediate carbon layer and lithium metaaluminate composite layer in sequence, and the intermediate carbon layer and lithium metaaluminate composite layer constitute the outer shell of the material . Wherein, the size of the inner core is 200nm, the thickness of the middle carbon layer is 10nm, and the thickness of the lithium metaaluminate composite layer is 10nm.

[0040] The preparation steps of lithium titanate electrode material are:

[0041] 1) Preparation of the raw material mixture for the intermediate carbon layer and the raw material mixture for the lithium metaaluminate composite layer:

[0042] Mix 50g of sucrose, 1g of sodium dodecylsulfonate, 1g of carbon nanotubes and 1000mL of acetic acid evenly to obtain a mixed solution A, which is the mixed solution of the intermediate carbon layer raw materials;

[0043] Mix 50g of li...

Embodiment 3

[0048] Lithium titanate electrode material with core-shell structure, the inner core is lithium titanate, along the inner core, there are intermediate carbon layer and lithium metaaluminate composite layer in sequence, and the intermediate carbon layer and lithium metaaluminate composite layer constitute the outer shell of the material . Wherein, the size of the inner core is 500nm, the thickness of the middle carbon layer is 50nm, and the thickness of the lithium metaaluminate composite layer is 50nm.

[0049] The preparation steps of lithium titanate electrode material are:

[0050] 1) Preparation of the raw material mixture for the intermediate carbon layer and the raw material mixture for the lithium metaaluminate composite layer:

[0051] Mix 200g of citric acid, 2g of sodium dodecylsulfonate, 2g of carbon nanotubes and 1000mL of benzoic acid evenly to obtain a mixed solution A, which is the mixed solution of the intermediate carbon layer raw materials;

[0052] Mix 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com