Processing method of mulberry leaf black tea with fruity flavor

A technology of mulberry leaf black tea and processing method, which is applied in the field of tea processing, can solve the problems of heavy beany smell, single aroma, and imperfection, and achieve the effect of solving heavy beany smell, simple processing technology and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

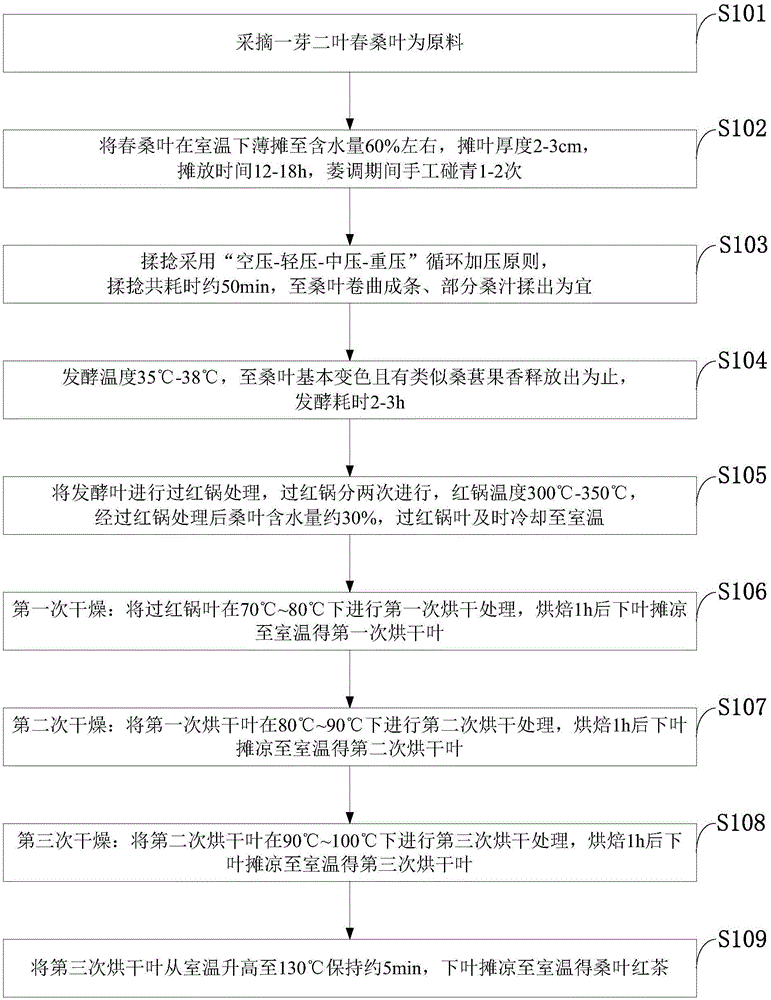

Image

Examples

Embodiment 1

[0030] (1) Raw materials: spring mulberry leaves with one bud and two leaves, leaves without rainwater and leaves with pests and diseases;

[0031] (2) Withering: at room temperature, spread the spring mulberry leaves thinly until the water content is 60% to 62%, the thickness of the spread leaves is 2-3cm, the withering time is 15h, and the green leaves are touched by hand once during the withering period;

[0032] (3) Kneading: Kneading adopts the principle of "air pressure-light pressure-medium pressure-heavy pressure-air pressure" cycle pressure, in which air pressure is 20min, light pressure is 5min, medium pressure is 15min, heavy pressure is 3min, air pressure is 1min, medium pressure Press for 13 minutes, heavy pressure for 2 minutes, and air pressure for 1 minute. After kneading, the mulberry leaves are basically curled and some mulberry juice is kneaded out;

[0033] (4) Fermentation: Fermentation temperature is 36°C to 38°C, relative humidity is about 90%, until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com