A kind of preparation method of p-aminobenzene-beta-hydroxyethyl sulfone sulfate

A technology of hydroxyethyl sulfone and p-aminobenzene, which is applied in the field of preparation of p-aminobenzene-β-hydroxyethyl sulfone sulfate, can solve the problems of product quality and yield gap, and achieve increased yield and product quality , to achieve the effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

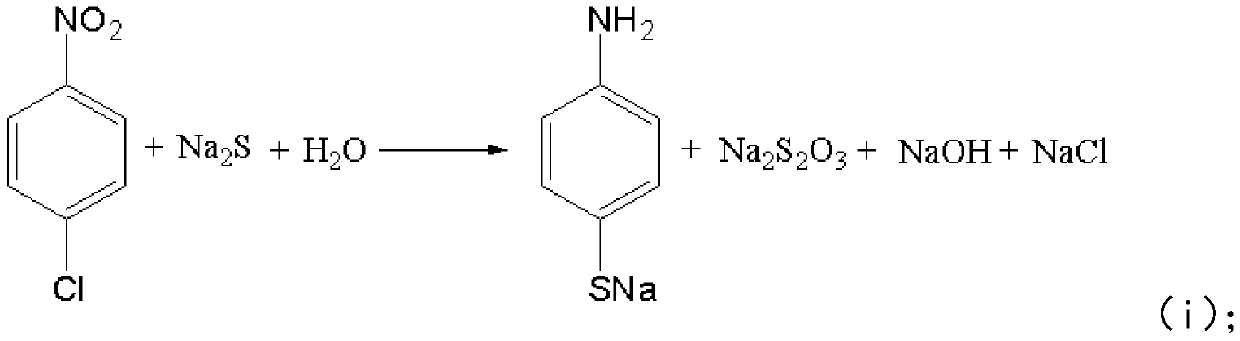

[0037] Specifically, the steps of the preparation method of the present invention are as follows:

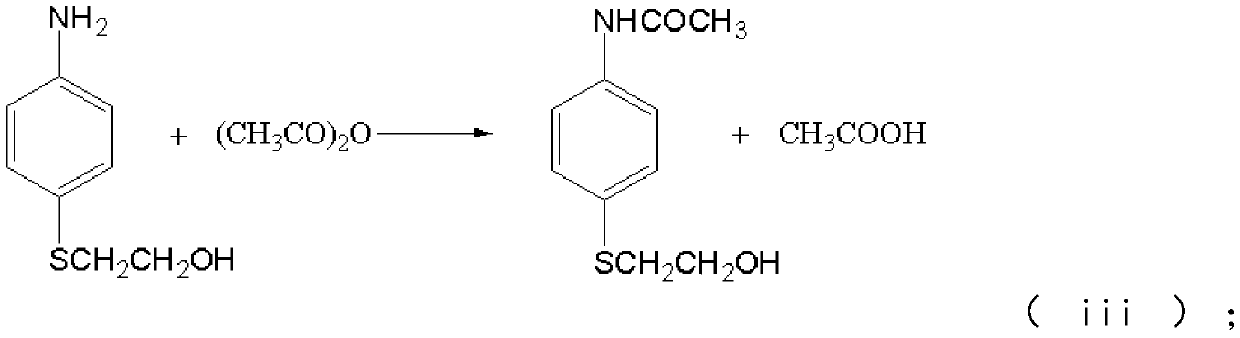

[0038] After reducing p-nitrochlorobenzene, it reacts and condenses with chloroethanol, then after the acylation reaction, catalyzes oxidation, and finally esterifies to obtain p-aminobenzene-β-hydroxyethyl sulfone sulfate;

[0039] By increasing the steps of the acylation reaction, the intermediate product can be made more stable, thereby further improving the quality of the product.

[0040] Preferably, the method steps of the present invention are as follows:

[0041] (i) Add water in p-nitrochlorobenzene, preferably, the mass ratio of p-nitrochlorobenzene and water is 50:100~110, more preferably, the mass ratio of p-nitrochlorobenzene and water is 50: 110;

[0042] Then, heat up and stir, and preferably heat up to 101-102°C;

[0043] Then, drop sodium sulfide solution, preferably, the mass percent of sodium sulfide solution used is 20~25%; More preferably, the mass percen...

Embodiment 1

[0080] (i) Add 50g of p-nitrochlorobenzene in the reaction kettle, then add 110g of water, stir and heat up to 101-102°C, start to add 60g of sodium sulfide solution (22%) dropwise, and the dropping time is controlled at 2-3 hours , after the dropwise addition is completed, the temperature of the reaction solution is controlled at 104-105°C;

[0081] Continue the reaction for 10 hours, then change the reflux device to a distillation device, distill out the by-product (a small amount of p-chloroaniline) at 106-108°C until the distillate is colorless, cool the reaction liquid to 5°C and filter, and collect the filtrate;

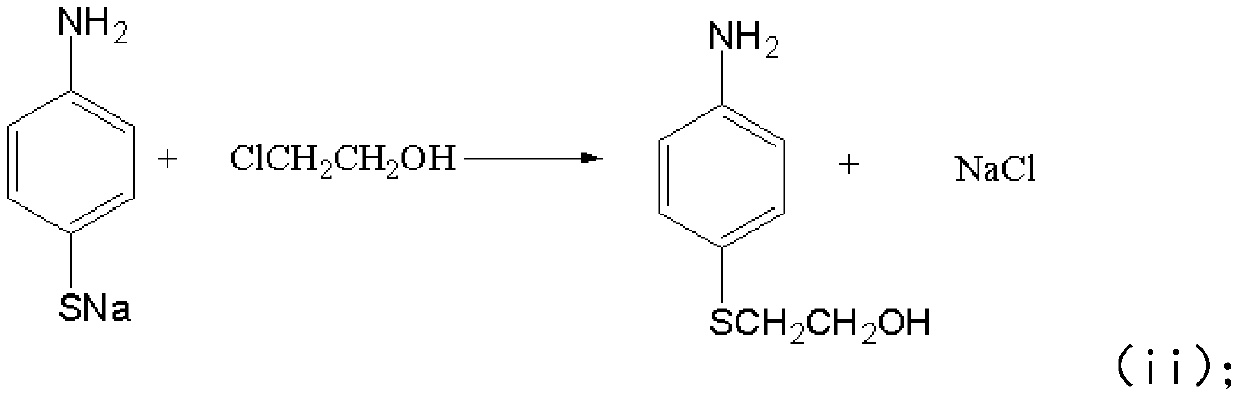

[0082] (ii) Move the filtrate obtained in step (i) into a reactor, add 80 g of chloroethanol (40%) at room temperature (cooled in a water bath) and stir for 1 hour, slowly add 40 mL of 36% hydrochloric acid, and stir for another 1 hour, and the reaction ends;

[0083] Pour the reaction solution into a 1000mL separatory funnel and let it stand for layering to se...

Embodiment 2

[0088] Prepare p-aminobenzene-β-hydroxyethyl sulfone sulfate with reference to the method of Example 1, wherein, in the step (i) of Example 2, the amount of water is 80g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com