Spherical carrier and olefin polymerization catalyst, preparation methods and application of spherical carrier and olefin polymerization catalyst, and olefin polymerization method

A spherical carrier, olefin polymerization technology, applied in the field of olefin polymerization, can solve the problems of poor propylene polymerization performance and easily broken catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In a second aspect, the present invention provides a method for preparing a spherical carrier, wherein the method includes the following steps:

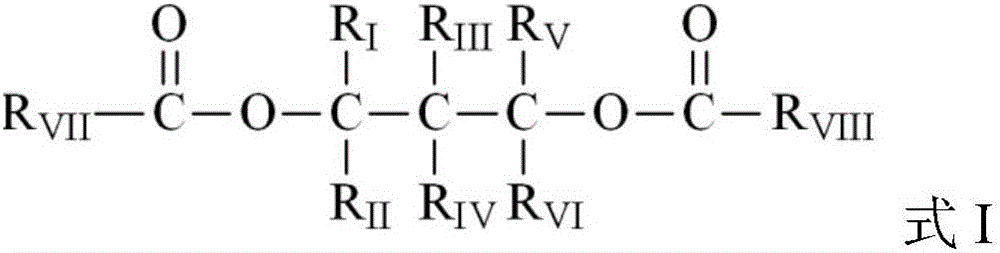

[0046] (1) The general formula is MgR m x 2-m The magnesium compound, the inorganic oxide and / or the precursor of the inorganic oxide, the glycol ester compound and the electron donor solvent are mixed to make a slurry;

[0047] (2) In an inert atmosphere, the slurry obtained in step (1) is spray-dried to obtain a spherical carrier;

[0048] Wherein, X is halogen, R is selected from C 1 -C 14 Alkyl, C 1 -C 14 Alkoxyl, C 6 -C 14 Aryl or C 6 -C 14 A group consisting of aryloxy groups, m is an integer of 0-2.

[0049] In the present invention, in step (1), the inorganic oxide may be silicon oxide and / or aluminum oxide, preferably silicon oxide, more preferably silicon dioxide. The inorganic oxide precursor may be silica sol and / or aluminum sol, preferably silica sol.

[0050] In the present invention, in step (1), the h...

Embodiment 1

[0104]This example is used to illustrate the preparation of the spherical carrier and olefin polymerization catalyst and the method of olefin polymerization in the present invention.

[0105] 1. Vector preparation

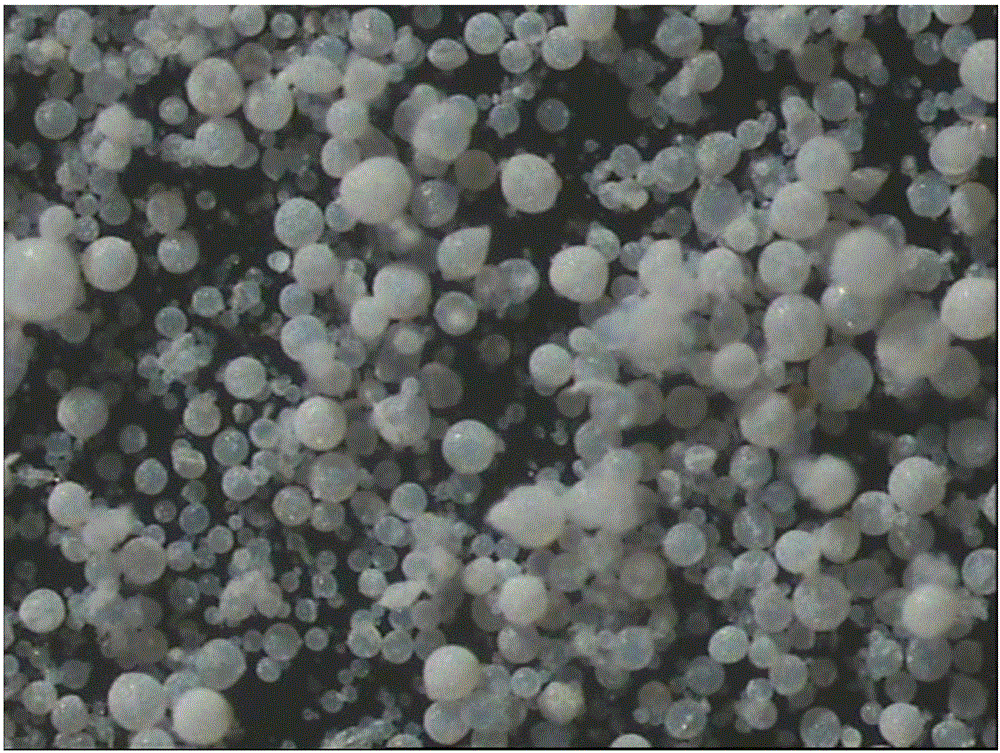

[0106] Add 9.5 g (0.1 mol) of magnesium chloride and 58 mL (1 mol) of ethanol into a stirred 500 mL glass reactor fully replaced by nitrogen, raise the temperature to 70° C. and keep for 1 h. The temperature was lowered to 0° C., then raised to 70° C., and 1.2 mL (0.004 mol) of 2,4-pentanediol dibenzoate was added during the warming. Maintained at 70°C for 2h, then lowered to 40°C and added 3.5g of silica gel, maintained at 40°C for 2h to obtain a slurry. The slurry was spray-dried, and the spray-drying conditions were: the inlet temperature was 200°C, and the outlet temperature was 106°C. The spherical carrier Z1 was prepared, and it was found that Z1 was basically spherical by optical microscope observation, and the results were as follows: figure 1 shown.

...

Embodiment 2

[0114] This example is used to illustrate the preparation of the spherical carrier and olefin polymerization catalyst and the method of olefin polymerization in the present invention.

[0115] 1. Vector preparation

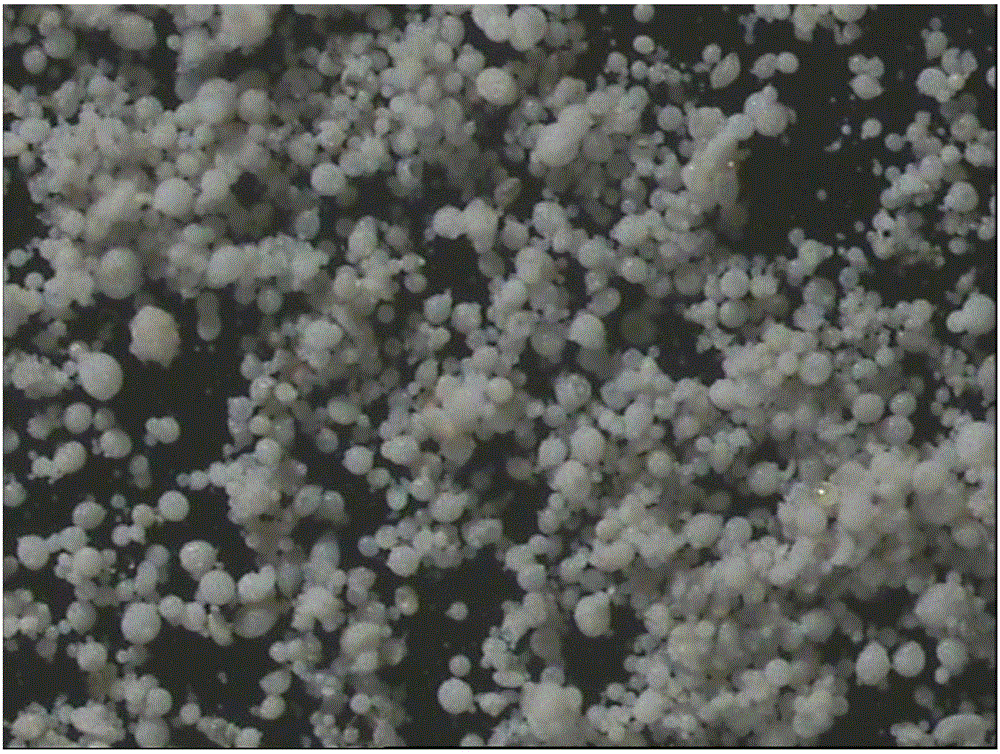

[0116] Add 9.5 g (0.1 mol) of magnesium chloride and 46 mL (0.79 mol) of ethanol into a stirred 500 mL glass reactor fully replaced by nitrogen, raise the temperature to 70° C. and keep for 1 h. The temperature was lowered to 0° C., then raised to 70° C., and 2 mL (0.0067 mol) of 2,4-pentanediol dibenzoate was added during the warming. Maintained at 70°C for 2h, then lowered to 40°C and added 2.8g of silica gel, maintained at 40°C for 2h to obtain a slurry. The slurry was spray-dried, and the spray-drying conditions were: the inlet temperature was 200°C, and the outlet temperature was 106°C. The spherical carrier Z2 was prepared, and observed by an optical microscope, it was found that Z2 was basically spherical.

[0117] 2. Catalyst preparation

[0118] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| isotactic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com