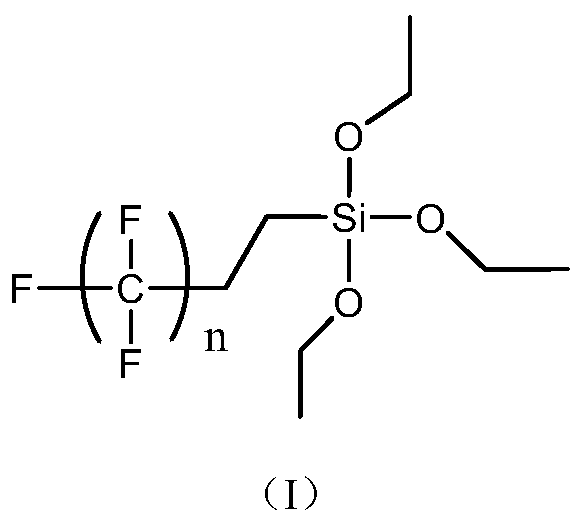

Internal electron donors, catalyst components, spherical-like catalysts for ethylene polymerization

An internal electron donor and ethylene polymerization technology, applied in the field of olefin polymerization, can solve the problems of unsatisfactory catalyst application, irregular catalyst shape, high catalyst production cost, etc., and achieve good hydrogen response ability, copolymerization performance, and good particle size distribution , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

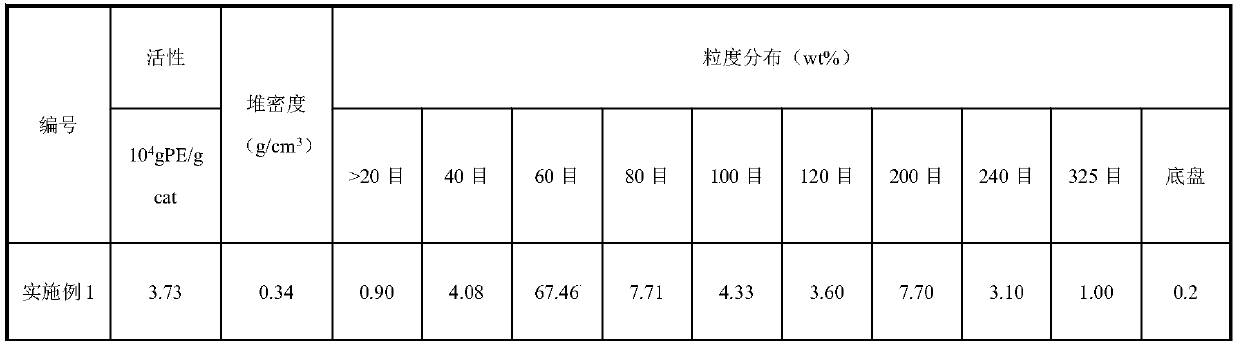

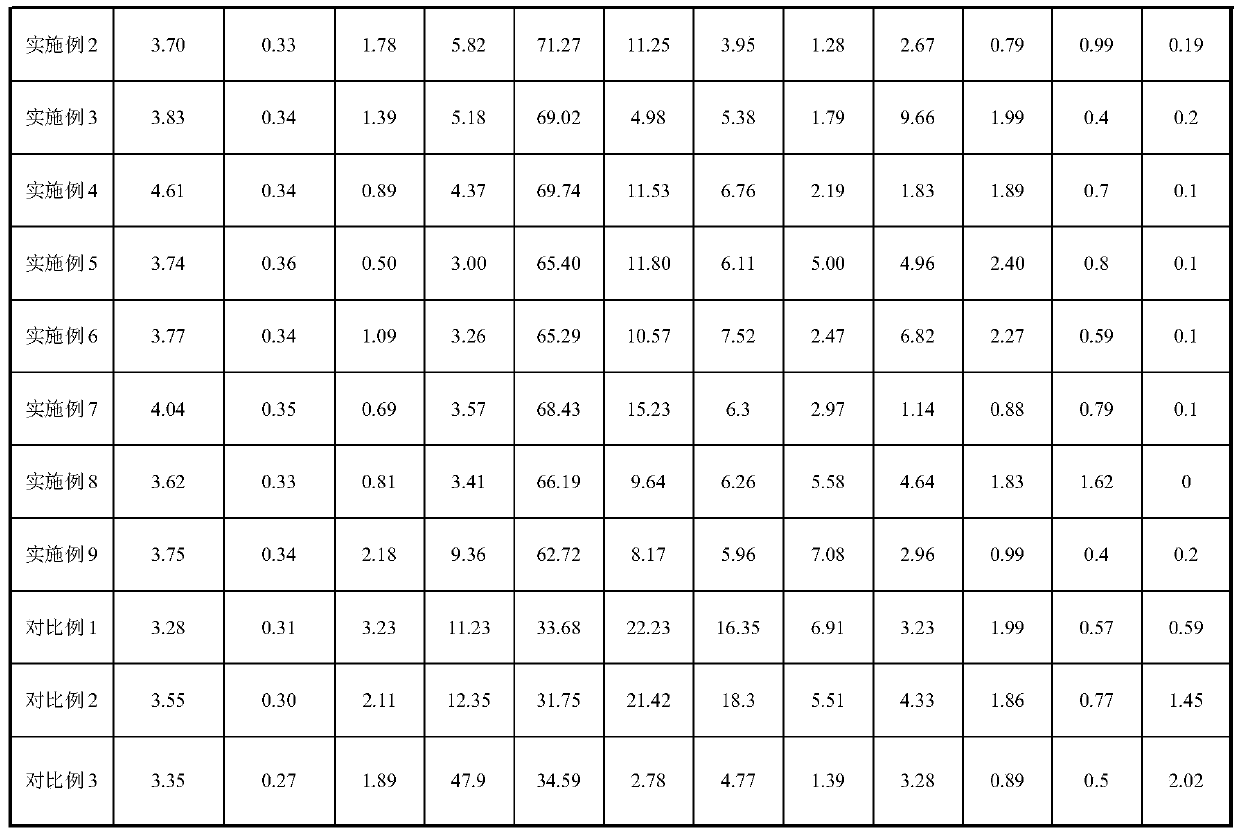

Examples

Embodiment 1

[0036] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. To this solution was added 15 mmol of 1H,1H,2H,2H-trifluoro-n-propyltriethoxysilane and stirred at 50°C for 2 hours to make 1H,1H,2H,2H-trifluoro-n-propyltriethoxysilane Oxysilane is dissolved in this solution. All the homogeneous solution obtained above was cooled to room temperature, and then added dropwise to 150 mL of titanium tetrachloride maintained at 0° C. within 1 hour while stirring. After completion of the dropwise addition, the temperature of the mixture was maintained at 0°C for 1 hour, then raised to 120°C over 2 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with hexane and decane respectively until no precipitated titanium ...

Embodiment 2

[0040] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. Add 15 mmol of 1H, 1H, 2H, 2H-pentafluoro-n-butyltriethoxysilane to this solution and stir at 50°C for 2 hours to make 1H, 1H, 2H, 2H-pentafluoro-n-butyltriethoxysilane Oxysilane is dissolved in this solution. All the homogeneous solution obtained above was cooled to room temperature, and then added dropwise to 150 mL of titanium tetrachloride maintained at 0° C. within 1 hour while stirring. After completion of the dropwise addition, the temperature of the mixture was maintained at 0°C for 1 hour, then raised to 120°C over 2 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with hexane and decane respectively until no precipitated titanium c...

Embodiment 3

[0044] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. Add 15 mmol of 1H, 1H, 2H, 2H-heptafluoro-n-pentyltriethoxysilane to the solution and stir at 50°C for 2 hours to make 1H, 1H, 2H, 2H-heptafluoro-n-pentyltriethoxysilane Oxysilane is dissolved in this solution. All the homogeneous solution obtained above was cooled to room temperature, and then added dropwise to 150 mL of titanium tetrachloride maintained at 0° C. within 1 hour while stirring. After completion of the dropwise addition, the temperature of the mixture was maintained at 0°C for 1 hour, then raised to 120°C over 2 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with hexane and decane respectively until no precipitated titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com