Silicon dioxide aerogel coating and application thereof

A technology of silica and airgel, applied in the direction of epoxy resin coating, polyester coating, polyurea/polyurethane coating, etc., can solve the problem of affecting the thermal insulation performance and film quality of airgel coating Porosity, affecting the performance of airgel and other issues, to achieve the effect of improving thermal insulation performance and film forming quality, shortening film forming time, and preventing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

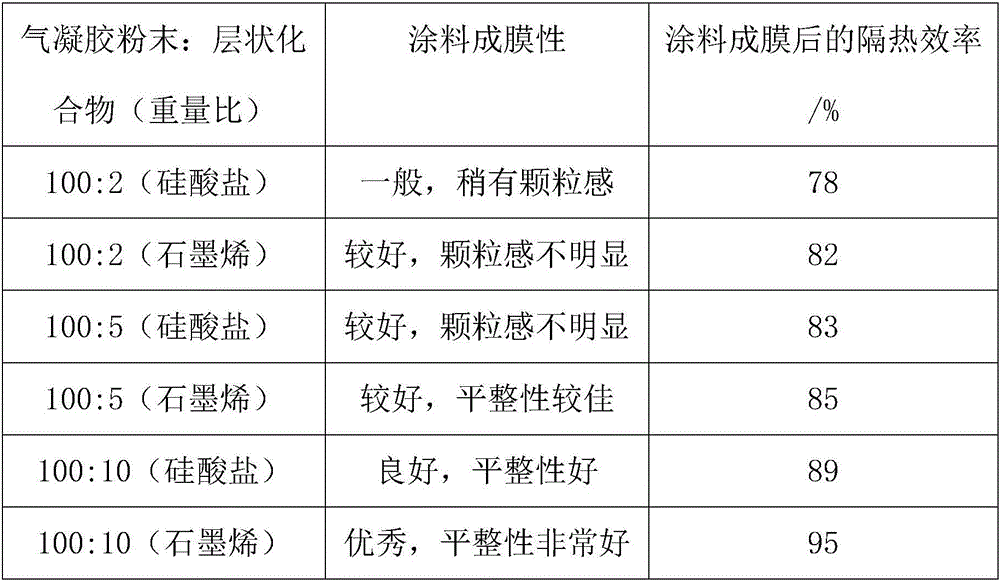

[0028] A silica airgel coating, comprising the following raw materials in parts by weight: 100 parts of airgel powder, 2-10 parts of layered compound, 10-100 parts of water-based paint, 2-10 parts of surfactant, 2-10 parts 1 part of film-forming aid, 1-5 parts of defoamer; the silica airgel coating is obtained by stirring and mixing the above raw materials in parts by weight in sequence.

[0029] Described mixing comprises the following steps:

[0030] S1, under the condition of high-speed stirring, the airgel powder is mixed with the layered compound to obtain the mixed powder A;

[0031] S2, under the condition of high-speed stirring, adopt the mode of vibration sieving, sieve the mixed powder A into the water-based paint, add surfactant, stir for 1-3h;

[0032] S3, under the condition of low-speed stirring, continue to add film-forming aids and defoamers to the water-based paint, and stir for 20-50 minutes to obtain a finished paint.

[0033] The airgel powder is made by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com