Silane-modified waterborne epoxy double-component zinc-rich paint composition and preparation method thereof

A silane-modified, water-based epoxy resin technology, used in the field of metal paint anti-corrosion, can solve the problems of insufficient water resistance, low VOC content, performance comparison, etc., and achieve good water dispersion stability, long-term anti-corrosion performance, and low VOC value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

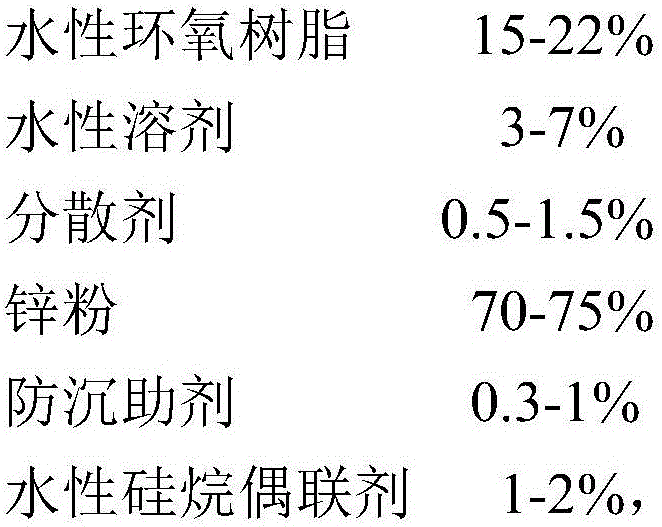

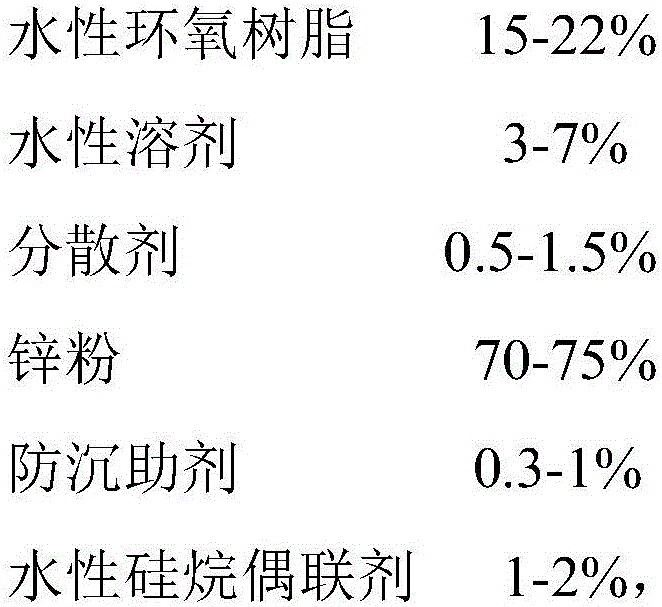

[0036] The first embodiment of the present invention firstly provides a silane-modified waterborne epoxy two-component zinc-rich coating composition. The composition is composed of a main agent and a curing agent. The main agent contains a water-based epoxy resin-based resin component.

[0037] The water-based epoxy resin in the present invention can be obtained according to the chemical modification method, which is also called the self-emulsification method, which involves introducing some hydrophilic groups into the epoxy resin molecular chain, or block or graft , so that the epoxy resin obtains self-emulsifying properties. When the modified polymer is emulsified with water, the hydrophobic polymer molecular chains will aggregate into particles, and ionic groups or polar groups are distributed on the surface of these particles. Because they have the same charge and repel each other, as long as certain kinetic conditions are met, a stable water-based epoxy resin emulsion ca...

no. 2 approach

[0058] In this embodiment, the present invention also provides a method for preparing a silane-modified waterborne epoxy two-component zinc-rich coating as described above, comprising the following steps:

[0059] a) The step of mixing other components in the main agent except the anti-sedimentation aid to obtain a mixture;

[0060] b) the step of adding an anti-sedimentation aid;

[0061] c) a step of dispersing the slurry obtained after step b),

[0062] Wherein, in step b), before adding the anti-sedimentation aid, the mixture is heated to above 40°C; in step c), the slurry is dispersed to a particle size below 40 μm.

[0063] According to the above-mentioned preparation method, it is characterized in that, in step a), the mixing is carried out under the stirring condition of 500-700 rpm, and the stirring time is 4-8 minutes.

[0064] In some preferred embodiments of the present invention, the method includes the following steps

[0065] In step a, according to the ratio...

no. 3 approach

[0074] In a third embodiment of the present invention, an article is provided that includes a substrate, and a protective coating formed over the substrate.

[0075] The protective coating may comprise a layer formed according to the coating composition described above in the first embodiment.

[0076] For the protective coating, without limitation, it can be a single coating or multiple coatings. The layer formed from the coating composition of the present invention may be a primer layer or a surface layer or an intermediate layer.

[0077] As the substrate to be protected, various metals are possible, especially ferrous substrates.

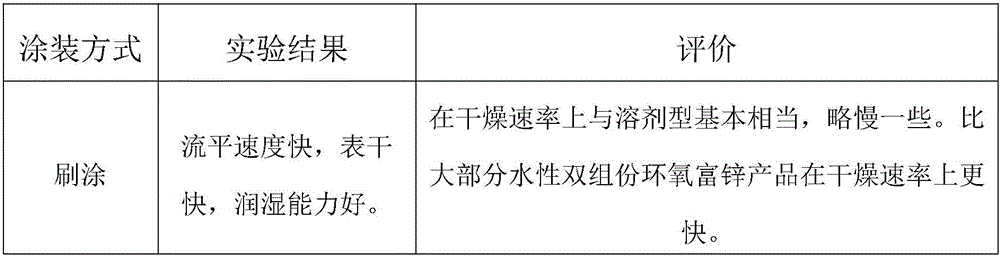

[0078] For the formation method of the above protective coating, it can be carried out according to the formation method of the same city in the art. Typically, spin coating, spray coating, etc. can be used. The thickness of the formed coating is not particularly limited, and may be from 50 μm to 1 mm.

[0079] The protective coating obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com