Dual-component dual-curing organic silicon composition

A dual-cure, silicone technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve problems such as difficult and fast deep curing, and worrying storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

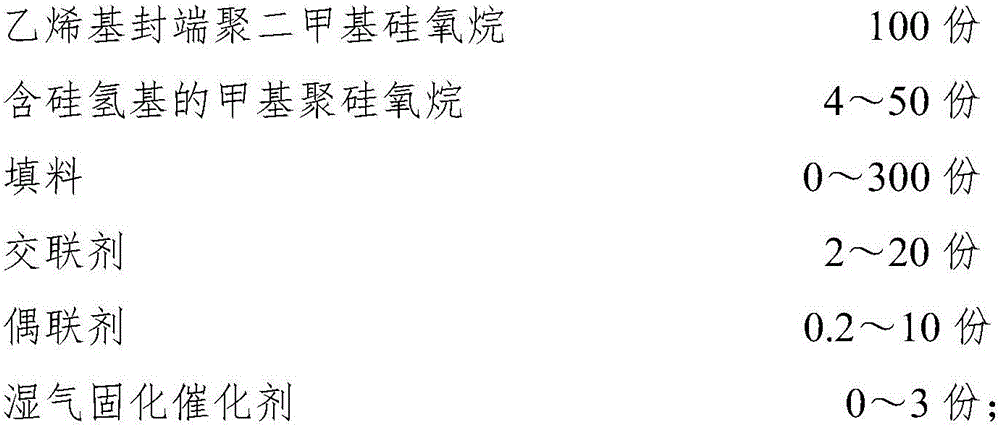

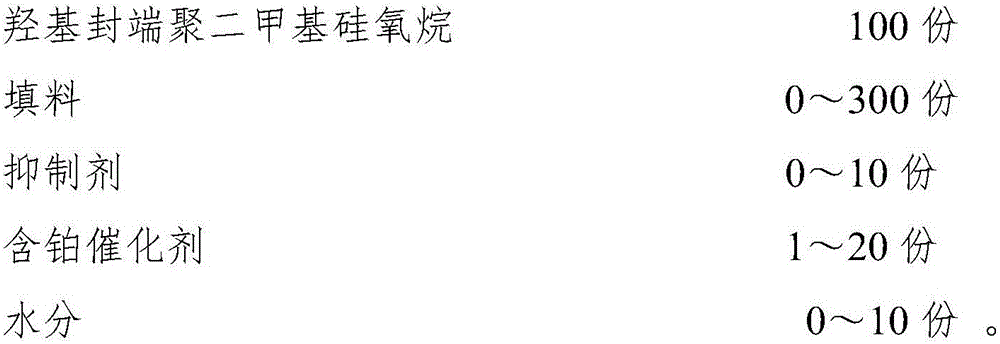

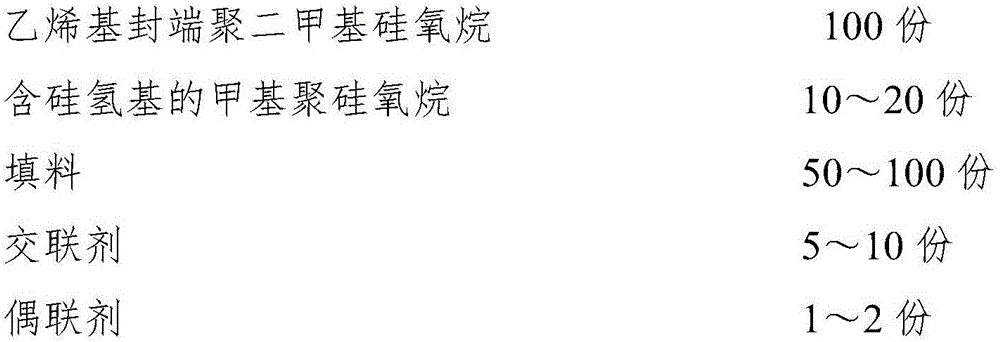

Method used

Image

Examples

Embodiment 1

[0031] Component A consists of 100 parts of vinyl-terminated polydimethylsiloxane with a viscosity of 10000mPa·s and a vinyl content of 0.15%, and 10 parts of a silicon hydrogen group-containing polydimethylsiloxane with a viscosity of 1000mPa·s and a hydrogen content of 0.2%. Methyl polysiloxane, 50 parts of light calcium carbonate, 8 parts of methyltrimethoxysilane, 1 part of bis(3-trimethoxysilylpropyl)amine.

[0032] Component B consists of 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 3000mPa·s, 10 parts of carbon black, 0.5 parts of ethynyl cyclohexanol, and 4 parts of tetramethyldichloroplatinic acid with a platinum content of 2000ppm. Vinyl disiloxane complex, 0.5 part moisture.

[0033] The weight ratio of A component and B component is 1.1:1, and the volume ratio is 1:1.

[0034] The mixture is heated at 100°C for 10 minutes to form a silicone rubber elastomer and bond simultaneously. It has cohesive bonding failure for aluminum alloy and...

Embodiment 2

[0039] Component A consists of 100 parts of vinyl-terminated polydimethylsiloxane with a viscosity of 20000mPa·s and a vinyl content of 0.10%, and 20 parts of a silicon hydrogen-containing polydimethylsiloxane with a viscosity of 5000mPa·s and a hydrogen content of 0.15%. Methylpolysiloxane, 100 parts of alumina powder, 6 parts of ethyltrimethoxysilane, 1 part of N-n-butylaminopropyltrimethoxysilane.

[0040] Component B consists of 100 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000mPa·s, 50 parts of heavy calcium carbonate, 0.4 parts of 2-ethyn-1-ol, and 8 parts of chloroplatinic acid with a platinum content of 2000ppm Tetramethyldivinyldisiloxane complex, 1 part moisture.

[0041] The weight ratio of A component and B component is 2.3:1, and the volume ratio is 2:1.

[0042] The mixture is heated at 120°C for 5 minutes to form a silicone rubber elastomer, which has cohesive bonding failure to aluminum alloy, stainless steel and other metal materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com