Green preparation method of high-purity galactooligosaccharide

A high-purity galacto-oligosaccharide technology, which is applied in the field of green preparation of high-purity galacto-oligosaccharides, can solve the problems of unfavorable large-scale production of high-purity GOS, high equipment requirements, and complicated operations, so as to be beneficial to industrial applications and The effects of promotion, fast growth and metabolic rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

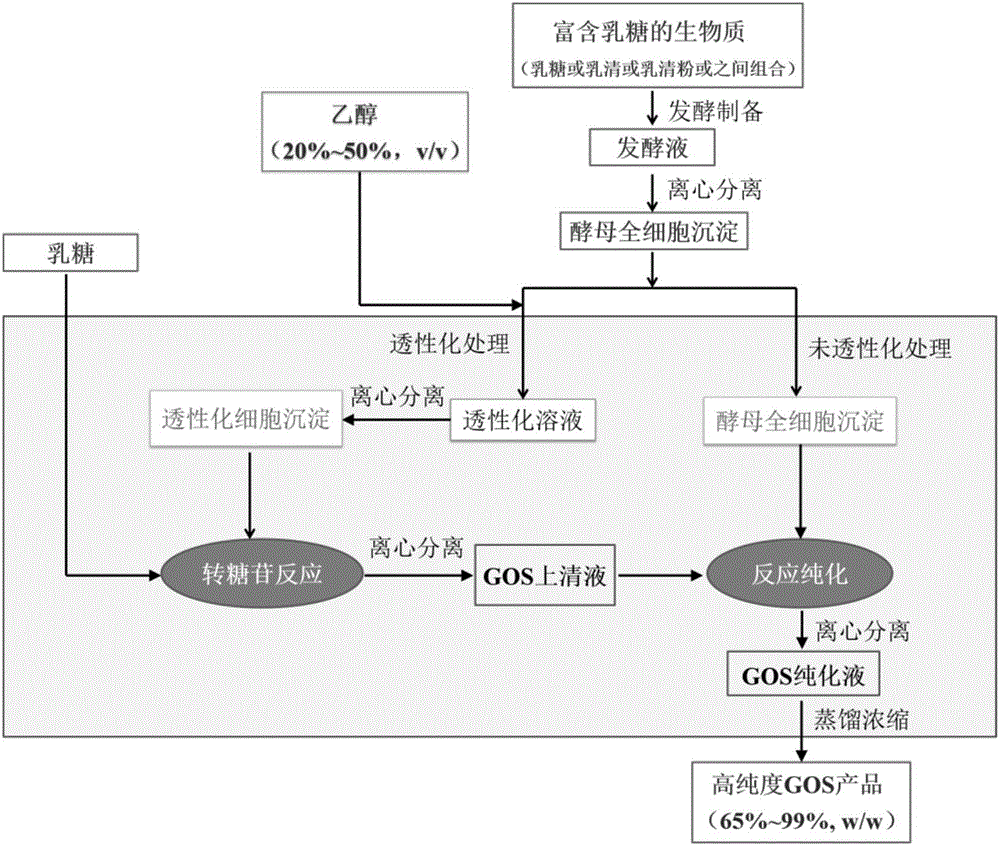

[0038] The green preparation method of high-purity galacto-oligosaccharide of the present invention ( figure 1 ), including the following steps:

[0039] 1) Fermentation preparation of whole yeast cells containing β-galactosidase intracellular enzyme

[0040] Inoculate yeast single clones into the seed liquid medium to prepare the yeast seed liquid, and then add 0.1-10% (v / v) yeast seed liquid to the lactose-rich biomass medium at a temperature of 16-37°C, stirring at a rotating speed It is prepared by fermentation under the conditions of 50-500 rpm and pH value of 4-10, and the fermentation time is 8 to 48 hours, and a fermentation broth containing whole yeast cells with a concentration of 1-20 g / L can be obtained.

[0041] 2) Use ethanol solution to permeabilize whole yeast cells

[0042] The above-mentioned fermentation broth is centrifuged to obtain yeast whole cell sediment and fermentation supernatant, which is used for permeabilization treatment and reaction purification of cru...

Embodiment 1

[0048] Fermentation Preparation of Pichia Pastoris Whole Cells Containing β-Galactosidase Intracellular Enzyme

[0049] The preserved Pichia pastoris strain was inoculated onto a flat solid LB medium and cultured at 30°C for 72 hours to obtain activated single colonies. The activated single colony was inoculated into liquid LB medium, and it was shaken and expanded for 20 hours at 30° C. and 160 rpm to obtain seed culture solution. In a 500mL Erlenmeyer flask, connect 0.1mL seed culture broth to 100mL fermentation medium, culture for 48h at the initial pH value of 4.0, rotating speed 50rpm, temperature 16℃, to obtain fermentation broth, and centrifuge to obtain whole Pichia yeast cells Precipitation and fermentation supernatant, Pichia pastoris whole cell precipitation is used for permeabilization and reaction purification of crude galactooligosaccharide (GOS), and the fermentation supernatant is removed. The formula of the fermentation medium is as follows: whey powder 100g / L, ...

Embodiment 2

[0057] Fermentation preparation of whole cells of Saccharomyces cerevisiae containing β-galactosidase intracellular enzyme

[0058] The preserved Saccharomyces cerevisiae strains were inoculated on a flat solid LB medium and cultured at 30°C for 72 hours to obtain activated single colonies. The activated single colony was inoculated into liquid LB medium, and it was shaken and expanded for 20 hours at 30° C. and 160 rpm to obtain seed culture solution. In a 500mL Erlenmeyer flask, insert 10mL seed culture solution into 100mL fermentation medium, culture for 8h at the initial pH value of 10, rotating speed of 500rpm, and temperature of 37℃ to obtain fermentation broth, and centrifuge to obtain the whole yeast Cell precipitation and fermentation supernatant, Saccharomyces cerevisiae whole cell precipitation is used for permeabilization and reaction purification of crude GOS, and fermentation supernatant is removed. The formula of the fermentation medium is as follows: whey 100mL / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com