A kind of preparation method of carboxymethyl maltodextrin

A technology of maltodextrin and carboxymethyl, which is applied in the field of preparation of carboxymethyl maltodextrin, to achieve the effect of expanding application field, improving quality and uniform reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

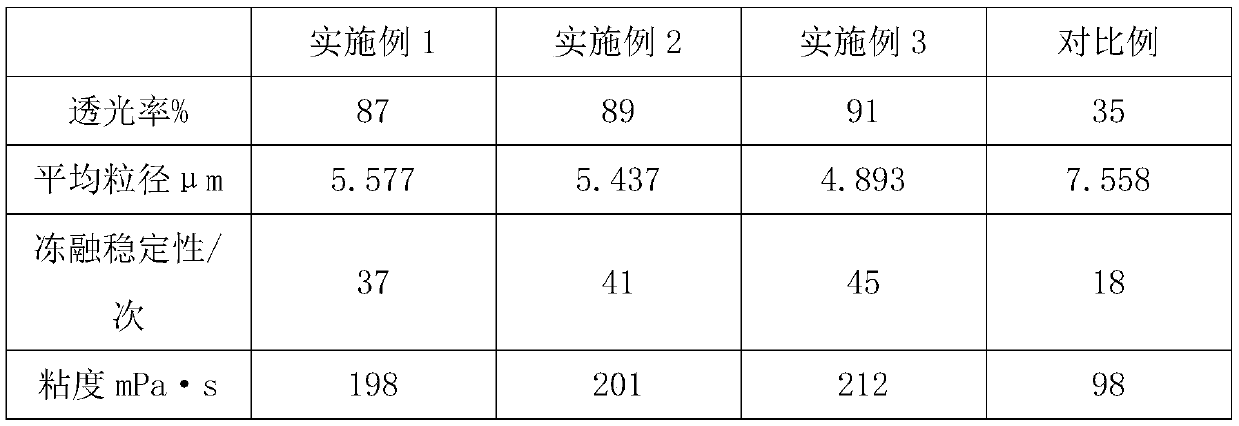

Examples

Embodiment 1

[0033] A preparation method of carboxymethyl maltodextrin, characterized in that: its preparation steps are as follows:

[0034] Step 1, adding maltodextrin into the reaction kettle, and then adding it into absolute ethanol to form a maltodextrin solution;

[0035] Step 2, add the dispersant to the maltodextrin solution, seal it for ultrasonic reaction for 10 minutes, let it stand for 20 minutes, and quickly release the pressure to obtain the expanded maltodextrin alcohol solution;

[0036] Step 3, adding sodium hydroxide to the expanded maltodextrin solution, and slightly boiling and refluxing for 1 hour to obtain an alkalized maltodextrin solution;

[0037] Step 4, slowly drop the alcohol solution of chloroacetic acid into the alkalized maltodextrin solution until it is completely dissolved, then carry out a pressurized heating reaction for 1 hour, rapidly cool down and filter to obtain sodium carboxymethyl maltodextrin;

[0038] Step 5: adding sodium carboxymethyl maltodex...

Embodiment 2

[0049] A preparation method of carboxymethyl maltodextrin, characterized in that: its preparation steps are as follows:

[0050] Step 1, adding maltodextrin into the reaction kettle, and then adding it into absolute ethanol to form a maltodextrin solution;

[0051] Step 2, add the dispersant to the maltodextrin solution, seal it for ultrasonic reaction for 20 minutes, let it stand for 20-30 minutes, and quickly release the pressure to obtain the expanded maltodextrin alcohol solution;

[0052] Step 3, adding sodium hydroxide to the expanded maltodextrin solution, and slightly boiling and refluxing for 2 hours to obtain an alkalized maltodextrin solution;

[0053] Step 4, slowly drop the alcohol solution of chloroacetic acid into the alkalized maltodextrin solution until it is completely dissolved, then carry out a pressurized heating reaction for 2 hours, rapidly cool down and filter to obtain sodium carboxymethyl maltodextrin;

[0054] Step 5: add sodium carboxymethyl maltod...

Embodiment 3

[0065] A preparation method of carboxymethyl maltodextrin, characterized in that: its preparation steps are as follows:

[0066] Step 1, adding maltodextrin into the reaction kettle, and then adding it into absolute ethanol to form a maltodextrin solution;

[0067] Step 2, add the dispersant to the maltodextrin solution, seal it for ultrasonic reaction for 15 minutes, let it stand for 25 minutes, and quickly release the pressure to obtain the expanded maltodextrin alcohol solution;

[0068] Step 3, adding sodium hydroxide to the expanded maltodextrin solution, and slightly boiling and refluxing for 2 hours to obtain an alkalized maltodextrin solution;

[0069] Step 4, slowly drop the alcohol solution of chloroacetic acid into the alkalized maltodextrin solution until it is completely dissolved, then carry out a pressurized heating reaction for 1 hour, rapidly cool down and filter to obtain sodium carboxymethyl maltodextrin;

[0070] Step 5: add sodium carboxymethyl maltodextr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com