Multilevel inverter power supply for electromagnetic stirring and control method for multilevel inverter power supply

A multi-level inverter and electromagnetic stirring technology, which is applied to electrical components, AC power input to DC power output, output power conversion devices, etc., can solve the problem of power thyristor system stability reduction, three-arm inverter power supply Complex structure, large number of switching devices, etc., to improve the characteristics of suppressing electromagnetic interference, increase system stability, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

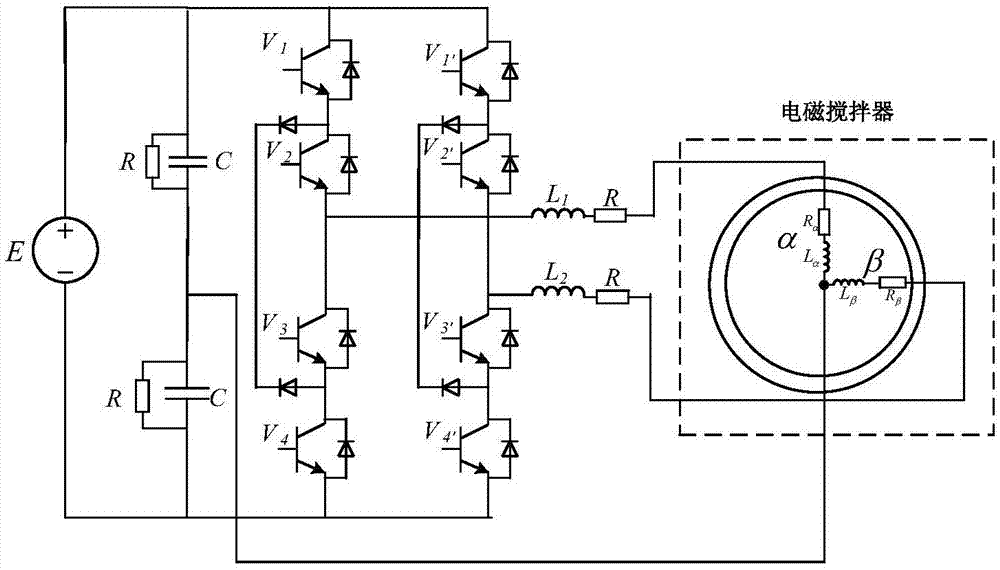

[0017] like figure 1 As shown, the present invention clamps the multi-level H-bridge inverter input terminal to be connected with two capacitors, is connected in parallel with a voltage equalizing resistor to balance the capacitor voltage, and supplies power to the capacitor from a DC stabilized voltage source; the inverter end is composed of 8 IGBTs and It is composed of diodes connected in antiparallel; 8 IGBTs are divided into two groups, and each group is connected in series with four IGBTs to form the left bridge arm and the right bridge arm. The center point of each bridge arm is connected to the head end of the induction coil of the motor. The left and right bridge arms are independent of each other, outputting an orthogonal current, which is filtered by the inductance to supply power to the induction coil; the ends of the two coil windings of the motor are connected together to the central tap of the capacitor.

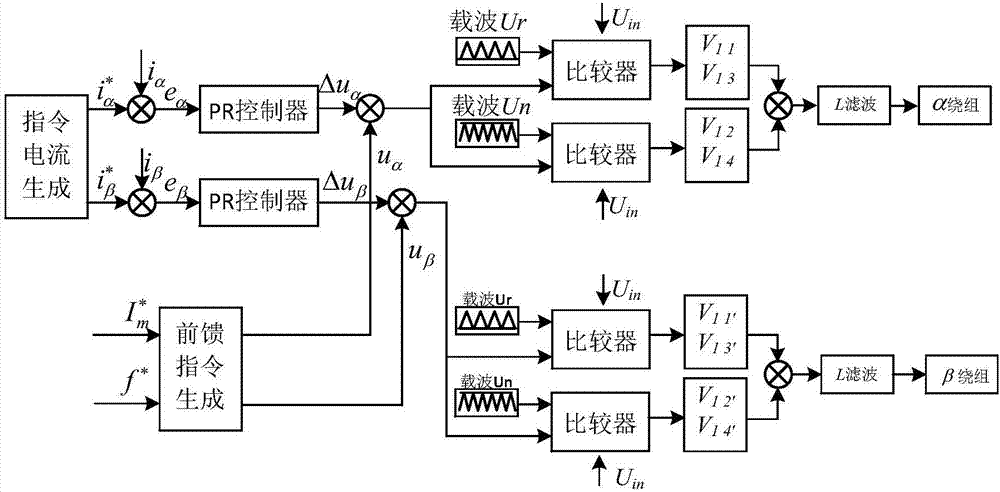

[0018] Control method of the present invention comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com