Caprolactam crystallizing device and using method

A caprolactam and crystallization device technology, applied in solution crystallization, organic chemistry and other directions, can solve the problems of difficult solid-liquid separation and washing and filtration, limiting the wide application of crystallization methods, low washing efficiency and other problems, achieving low breakage rate and high production efficiency. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

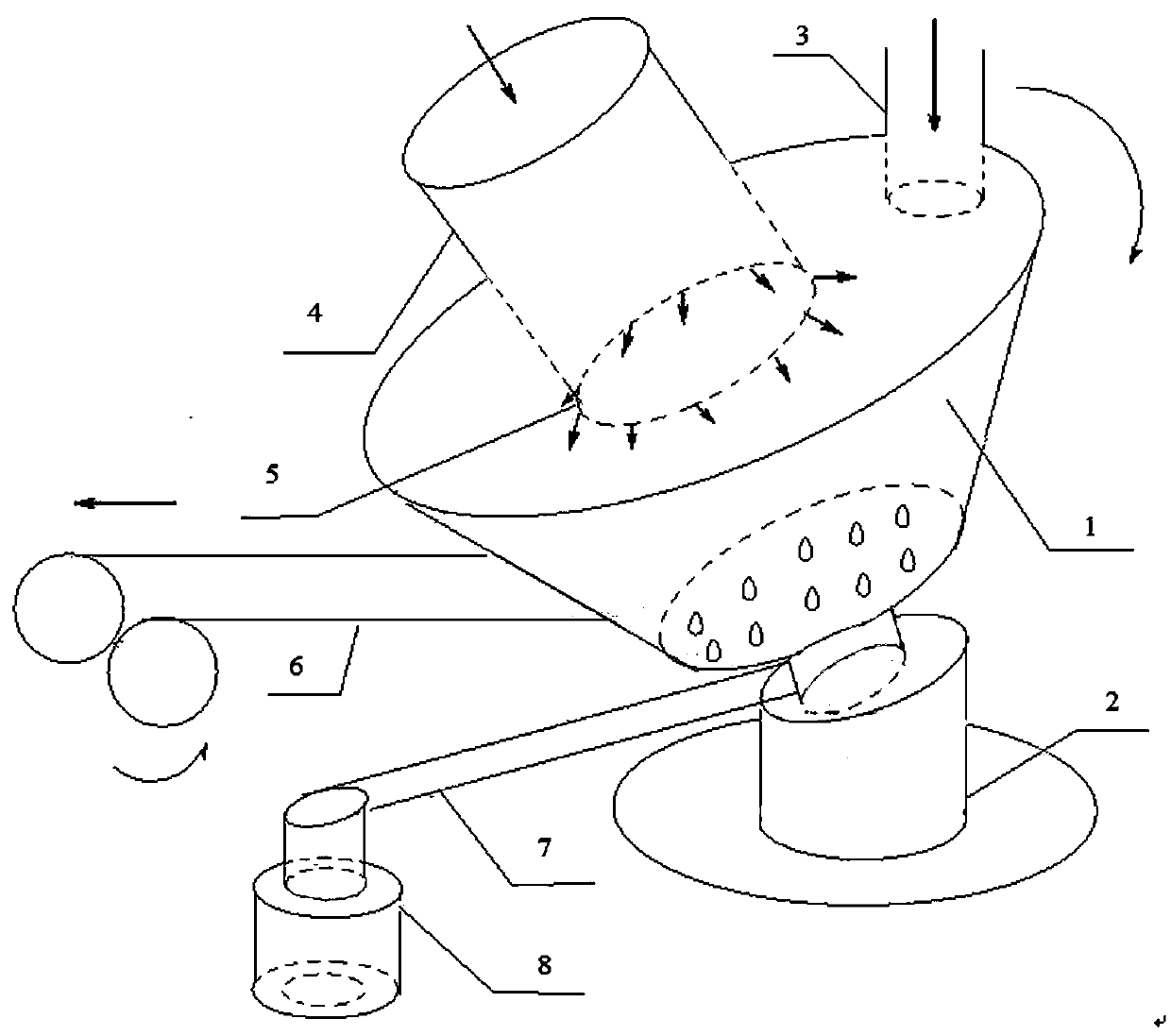

[0030] See attached figure 1 , caprolactam crystallization device of the present invention, comprises crystallization tank 1, base 2, material pipe 3, ventilation pipe 4, gas distributor 5, conveyer belt 6, transmission chain 7 and motor 8; Described crystallization tank 1 is inclined to be set, and the inclination is controlled 30-50 ° The crystallization tank 1 is connected with the base 2 and the transmission chain 7 respectively, and the transmission chain 7 is connected with the motor 8; the ventilation pipe 4 is connected with the gas distributor 5, and the gas distributor 5 is located inside the crystallization tank 1 The material pipe 3 is located at the top of the crystallization tank 1, and the bottom of the material tube 3 is lower than the upper edge of the crystallization tank 1; the conveyor belt 6 is located at the bottom of the crystallization tank 1, and one end of the conveyor belt 6 is positioned at the lower edge of the crystallization tank 1 and is vertica...

Embodiment 2

[0032] See attached figure 1 , caprolactam crystallization device of the present invention, comprises crystallization tank 1, base 2, material pipe 3, ventilation pipe 4, gas distributor 5, conveyer belt 6, transmission chain 7 and motor 8; Described crystallization tank 1 is inclined to be set, and the inclination is controlled for 35 ° The crystallization tank 1 is connected with the base 2 and the transmission chain 7 respectively, and the transmission chain 7 is connected with the motor 8; the ventilation pipe 4 is connected with the gas distributor 5, and the gas distributor 5 is located inside the crystallization tank 1 The material pipe 3 is located at the top of the crystallization tank 1, and the bottom of the material tube 3 is lower than the upper edge of the crystallization tank 1; the conveyor belt 6 is located at the bottom of the crystallization tank 1, and one end of the conveyor belt 6 is positioned at the lower edge of the crystallization tank 1 and is vertic...

Embodiment 3

[0034] See attached figure 1 , caprolactam crystallization device of the present invention, comprises crystallization tank 1, base 2, material pipe 3, ventilation pipe 4, gas distributor 5, conveyer belt 6, transmission chain 7 and motor 8; Described crystallization tank 1 is inclined to be set, and the inclination is controlled for 45 ° The crystallization tank 1 is connected with the base 2 and the transmission chain 7 respectively, and the transmission chain 7 is connected with the motor 8; the ventilation pipe 4 is connected with the gas distributor 5, and the gas distributor 5 is located inside the crystallization tank 1 The material pipe 3 is located at the top of the crystallization tank 1, and the bottom of the material tube 3 is lower than the upper edge of the crystallization tank 1; the conveyor belt 6 is located at the bottom of the crystallization tank 1, and one end of the conveyor belt 6 is positioned at the lower edge of the crystallization tank 1 and is vertic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com