A kind of water-based coating film material for touch screen and its preparation method and application

A technology for water-based coating and film materials, applied in radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of increasing the use of water-based coating materials problems such as poor ability to achieve the effect of improving the intensity of electromagnetic radiation, weakening the long-term cumulative effect, and solving the damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

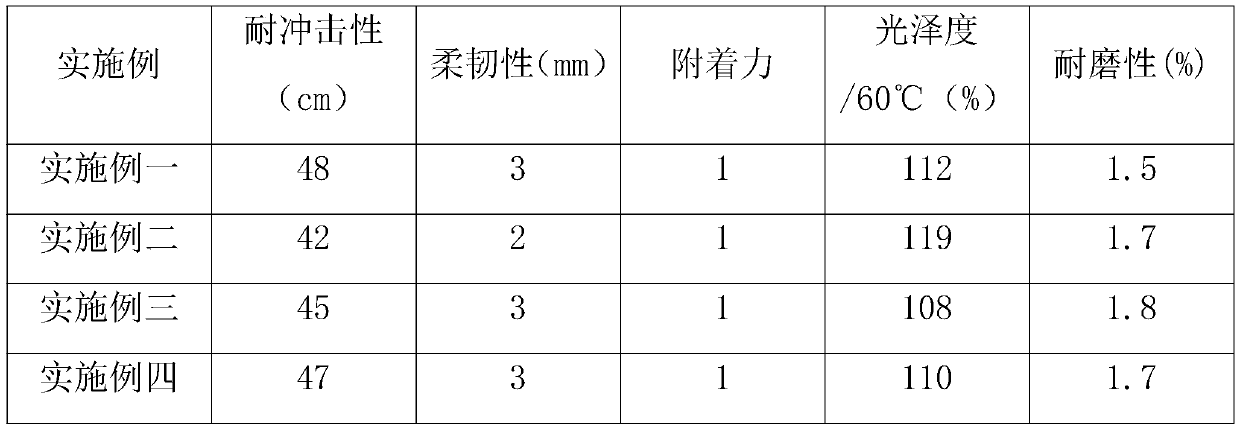

Embodiment 1

[0026] A water-based coating material for anti-electromagnetic radiation clothing, comprising the following raw materials in parts by weight: 70 parts of polyurethane acrylate composite emulsion, 15 parts of glucose, 1 part of iron powder, 0.6 part of nickel powder, and 2 parts of dipropylene glycol methyl ether , 0.8 parts of defoaming agent, 0.2 parts of wetting agent, 0.15 parts of slip agent, and 0.2 parts of leveling agent, wherein the particle size of iron powder and nickel powder is 10-20nm. Its preparation method is as follows:

[0027] Put the glucose into a beaker, add deionized water 15 times the weight of the glucose, and stir magnetically for about 10 minutes to dissolve the glucose completely. Under the condition of reaction for 10h, after the reaction was completed, it was lowered to room temperature, the dark brown solution in the kettle was centrifuged, and the supernatant was removed, and the precipitate was washed with absolute ethanol and deionized water su...

Embodiment 2

[0029] A water-based coating material for anti-electromagnetic radiation clothing, comprising the following raw materials in parts by weight: 80 parts of polyurethane acrylate composite emulsion, 20 parts of glucose, 2 parts of iron powder, 1.0 part of nickel powder, and 4 parts of dipropylene glycol methyl ether , 1.0 part of defoamer, 0.3 part of wetting agent, 0.25 part of slip agent, 0.3 part of leveling agent, wherein the particle size of iron powder and nickel powder is 10-20nm. Its preparation method is as follows:

[0030] Put the glucose into a beaker, add deionized water 20 times the weight of the glucose, and stir magnetically for about 10 minutes to dissolve the glucose completely. Under the condition of reaction for 10h, after the reaction was completed, it was lowered to room temperature, the dark brown solution in the kettle was centrifuged, and the supernatant was removed, and the precipitate was washed with absolute ethanol and deionized water successively unt...

Embodiment 3

[0032] A water-based coating material for anti-electromagnetic radiation clothing, comprising the following raw materials in parts by weight: 75 parts of polyurethane acrylate composite emulsion, 17 parts of glucose, 1.5 parts of iron powder, 0.8 part of nickel powder, and 3 parts of dipropylene glycol methyl ether , 0.9 parts of defoaming agent, 0.25 parts of wetting agent, 0.20 parts of slip agent, and 0.25 parts of leveling agent, wherein the particle size of iron powder and nickel powder is 10-20nm. Its preparation method is as follows:

[0033] Put the glucose into a beaker, add 16 times the weight of glucose in deionized water, and stir magnetically for about 10 minutes to dissolve all the glucose. Under the condition of reaction for 10h, after the reaction was completed, it was lowered to room temperature, the dark brown solution in the kettle was centrifuged, and the supernatant was removed, and the precipitate was washed with absolute ethanol and deionized water succe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com