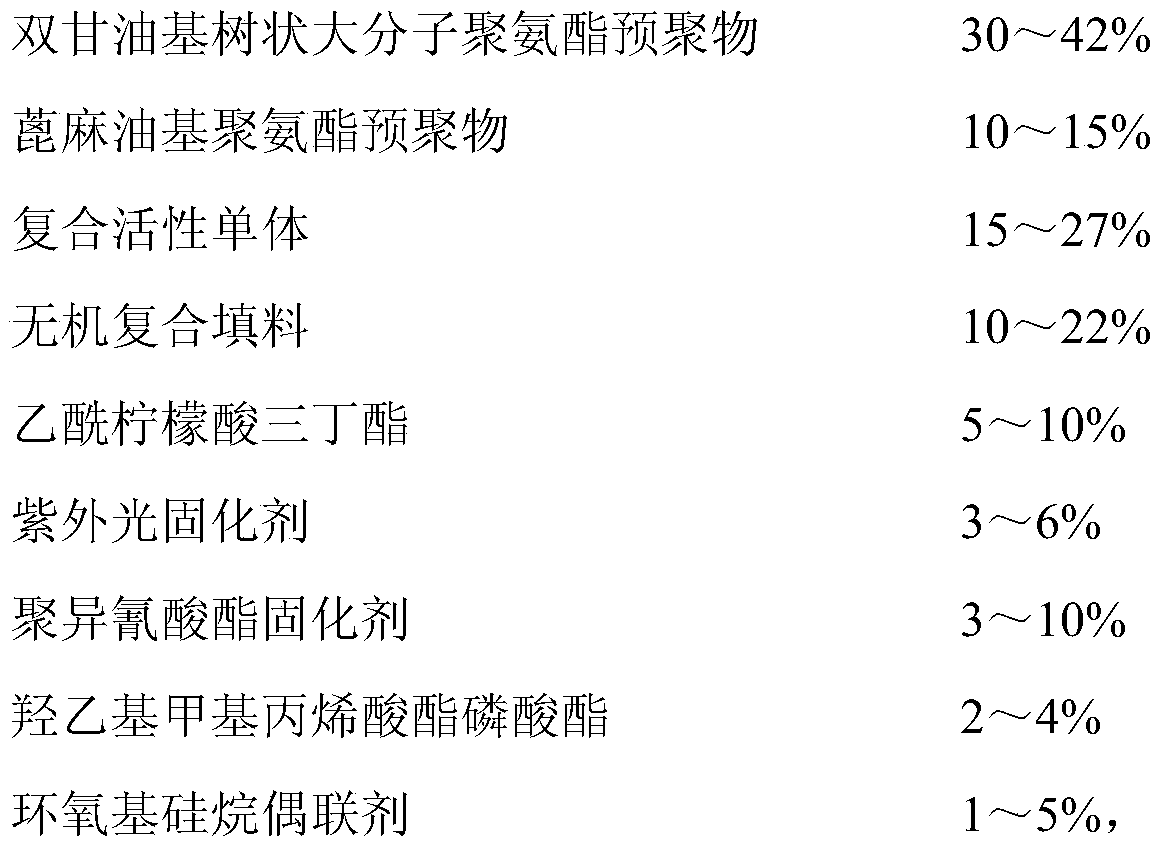

A kind of dual curing solvent-free polyurethane coil coating and preparation method thereof

A dual-curing, coil coating technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high viscosity of gel and prepolymer systems, inconvenient production process, etc., to achieve cost reduction, good comprehensive performance, The effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

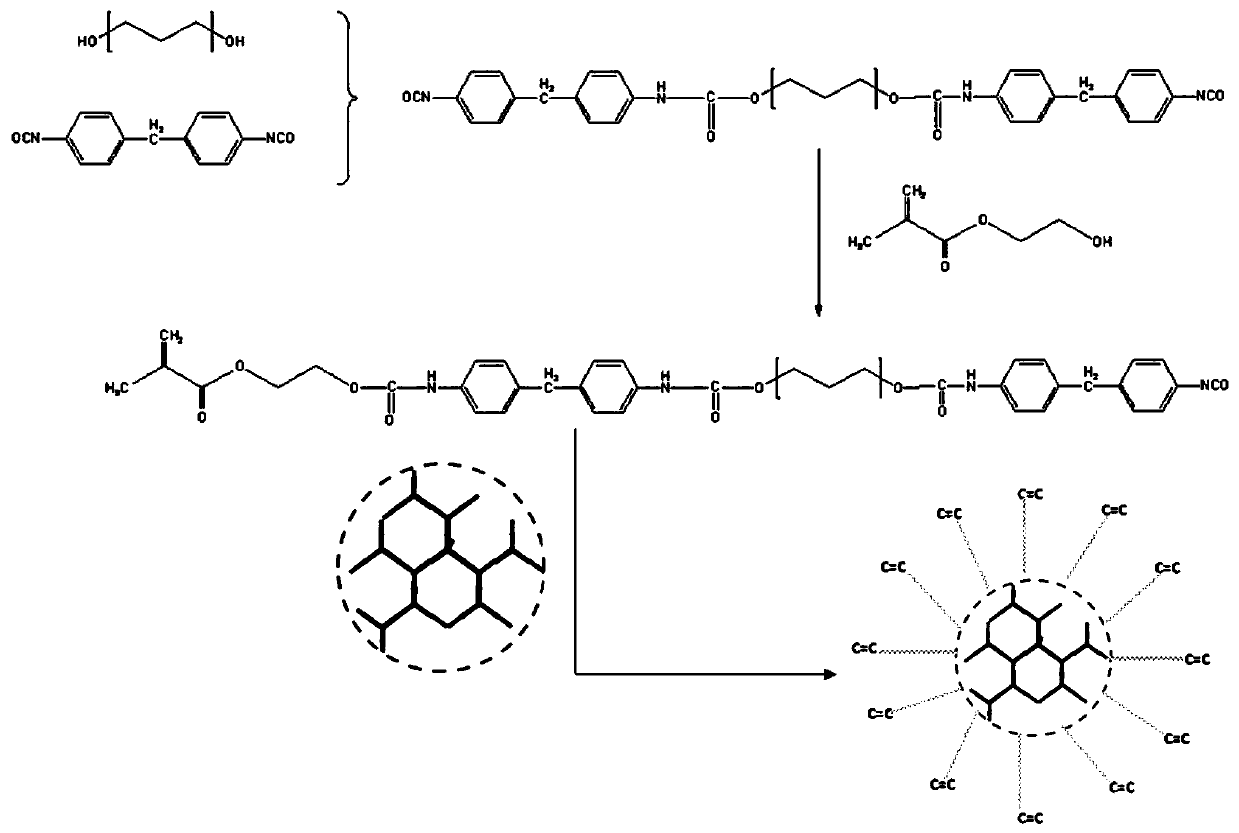

[0039] (1) Add 14.38gMDI and 0.1g bismuth-zinc composite catalyst (BiCAT8) into 100mL four-necked flask F 1 Finally, under the condition of maintaining 30 ° C after the nitrogen gas is stabilized, a mixed liquid of 5.71 g of polyoxypropylene diol with a molecular weight of 400 and 10.71 g of polyethylene glycol with a molecular weight of 1000 is gradually added to it, and the reaction is stirred at a speed of 1000 r / min. 1h, to obtain reactant A,

[0040] (2) Add 3.25 g of hydroxyethyl methacrylate to the reactant A obtained in step (1), stir and react at a speed of 800 r / min at 40°C for 1.5 hours to obtain a reactant mixture B, which is mainly one end Urethane acrylates containing isocyanate groups with a carbon-carbon double bond at the other end,

[0041] (3) Under a nitrogen atmosphere, add 0.52g of diglycerin and 0.01g of p-toluenesulfonic acid into a 100mL four-necked flask F 2 At 155°C, add 1.67g of bismethylolpropionic acid and 0.02g of p-toluenesulfonic acid, stir a...

Embodiment 2

[0049] Did not add diglyceryl dendrimer polyurethane prepolymer in the paint system; But the add-on of castor oil-based polyurethane prepolymer increases correspondingly, promptly the add-on in paint system becomes 45g; Other operation steps are identical with embodiment 1 .

Embodiment 3

[0051] Castor oil-based polyurethane prepolymer is not added in the coating system; but the addition of diglyceryl dendrimer polyurethane prepolymer increases accordingly, that is, the addition in the coating system becomes 45g; other operating steps are the same as in Example 1 .

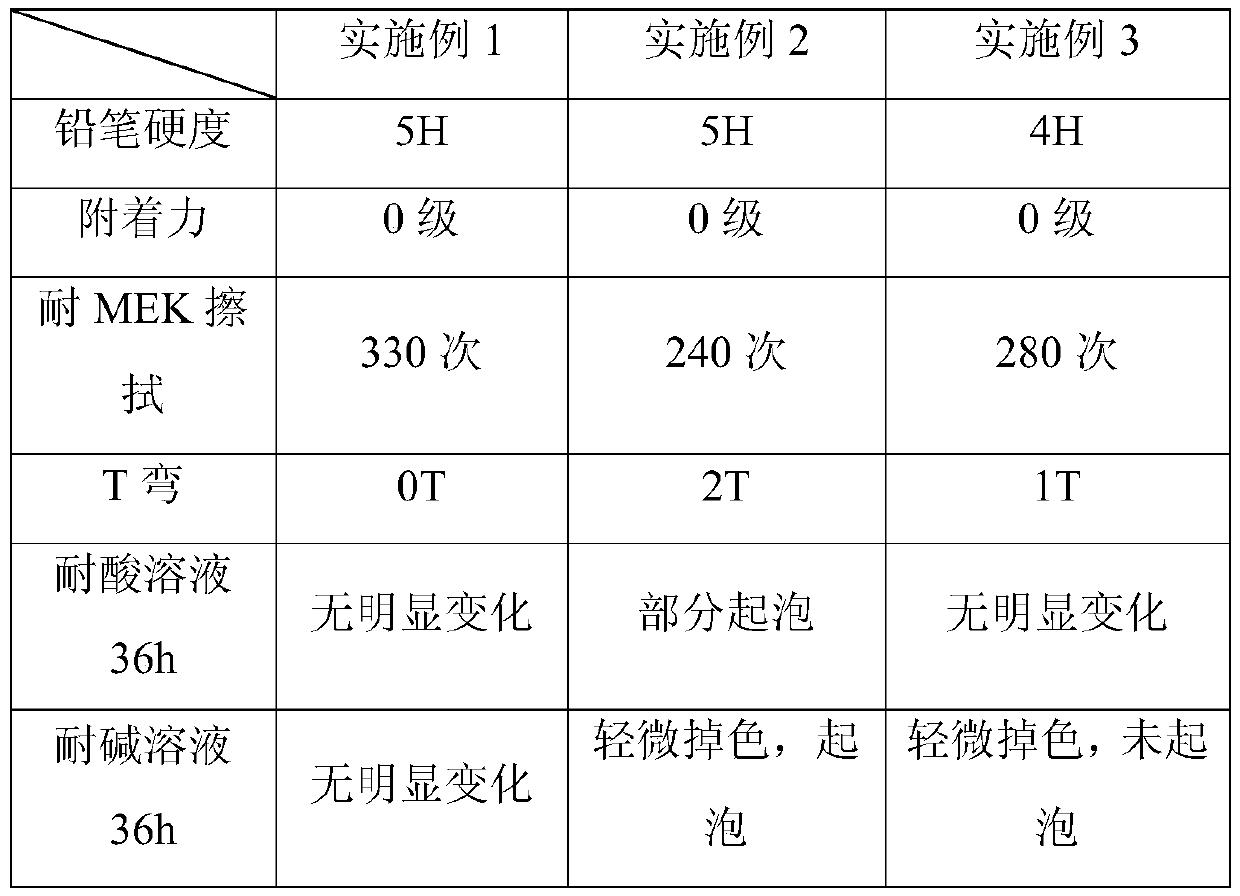

[0052] Table 1: Performance comparison of the coating films of Examples 1 to 3

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com