Niobium-containing austenitic stainless steel post welding heat treatment technology and fluidized bed

A post-weld heat treatment technology for austenitic stainless steel, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of troublesome disassembly and maintenance, large energy consumption, large volume of fluidized bed, etc., and achieve compact structure , Small footprint, good gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

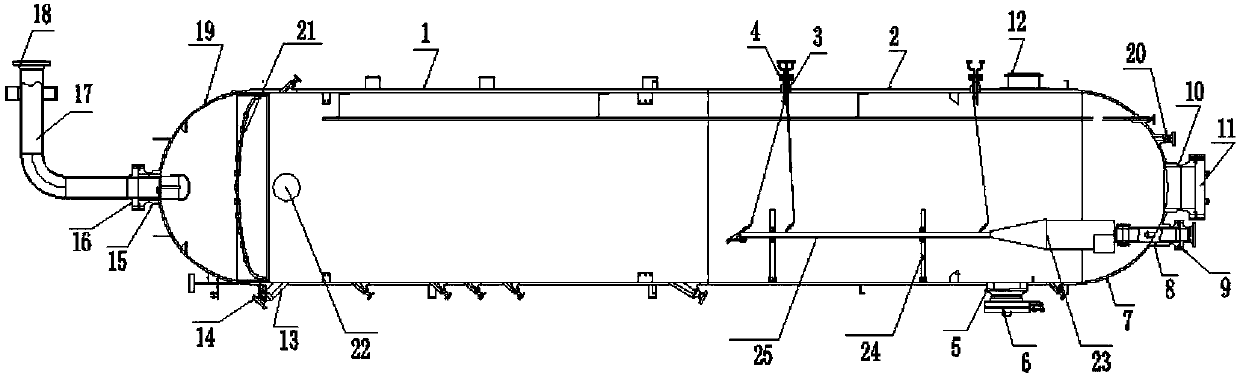

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

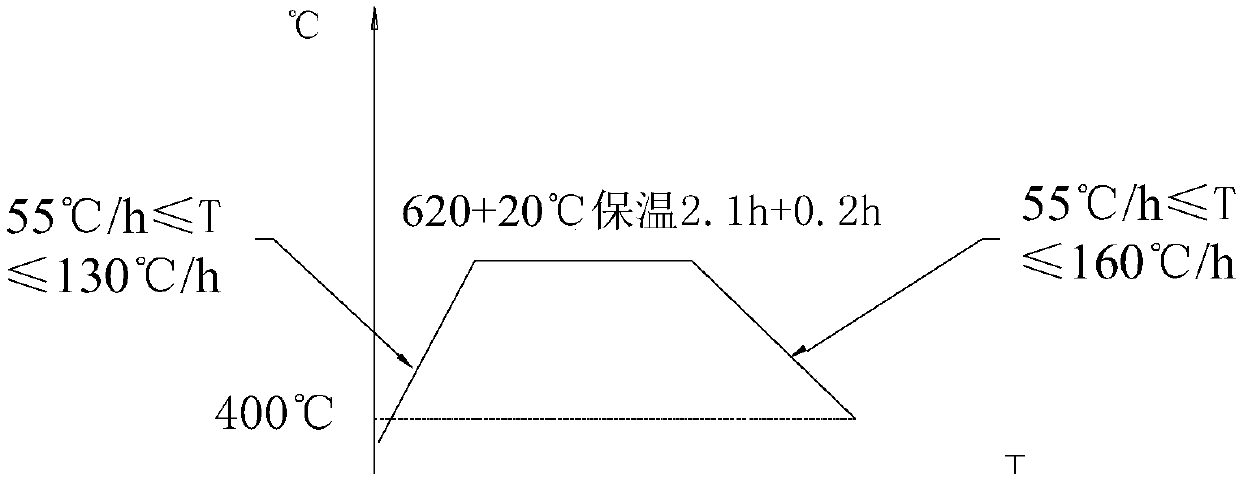

[0034]A post-weld heat treatment process for niobium-containing austenitic stainless steel provided by the invention comprises the following steps:

[0035] 1) Analyze the composition and properties of niobium-containing austenitic stainless steel;

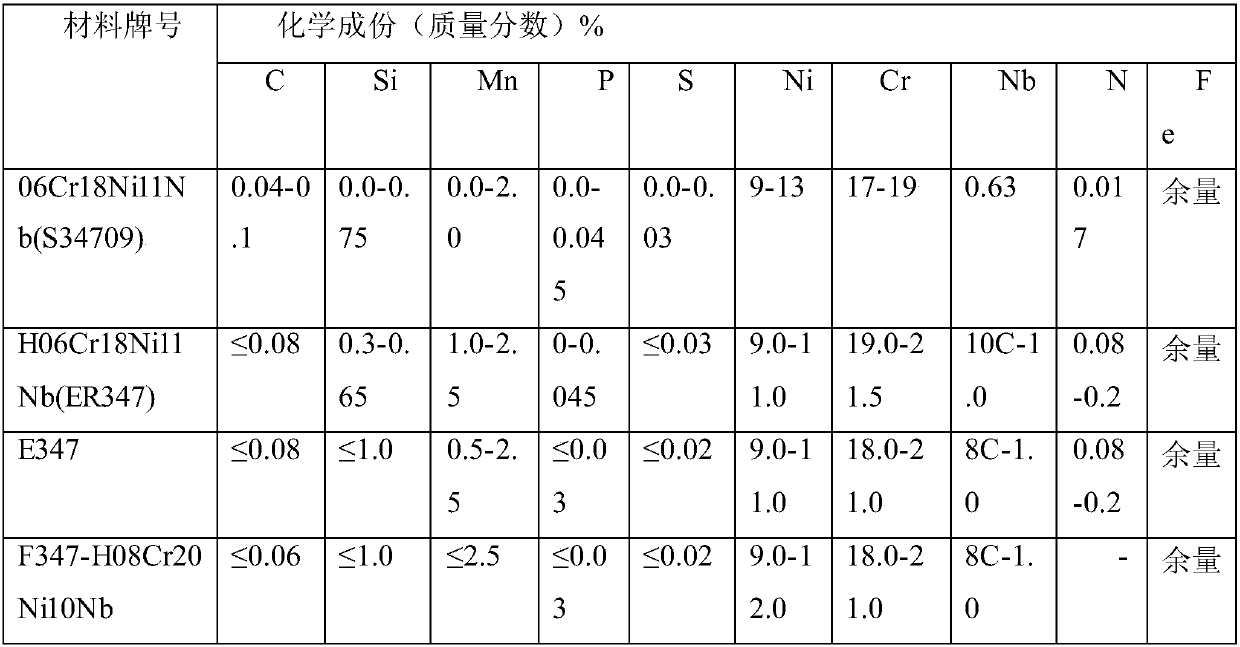

[0036] Niobium-containing austenitic stainless steel 06Cr18Ni11Nb (S34709) adds niobium as a stabilizing alloy element on the basis of austenitic stainless steel 06Cr19Ni10, and appropriately increases nickel to control the carbon content range from 0.04 to 0.10%. After solid solution treatment of solid stainless steel under heat preservation and water cooling at 1050°C and stable heat treatment at 800-900°C for 2 hours, the stabilizing element niobium and carbon form high melting point carbides and solid dissolve in austenite gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com