Lithium ion battery positive electrode material, lithium ion battery positive pole plate and lithium ion battery

A lithium-ion battery and cathode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as affecting the driving safety of electric vehicles, poor high temperature performance, and low energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 13

[0086] Except for Example 13, the graphene used in each embodiment and comparative example is prepared by the above-mentioned Hummers method, and the specific surface area of graphene is 36~38m 2 / g.

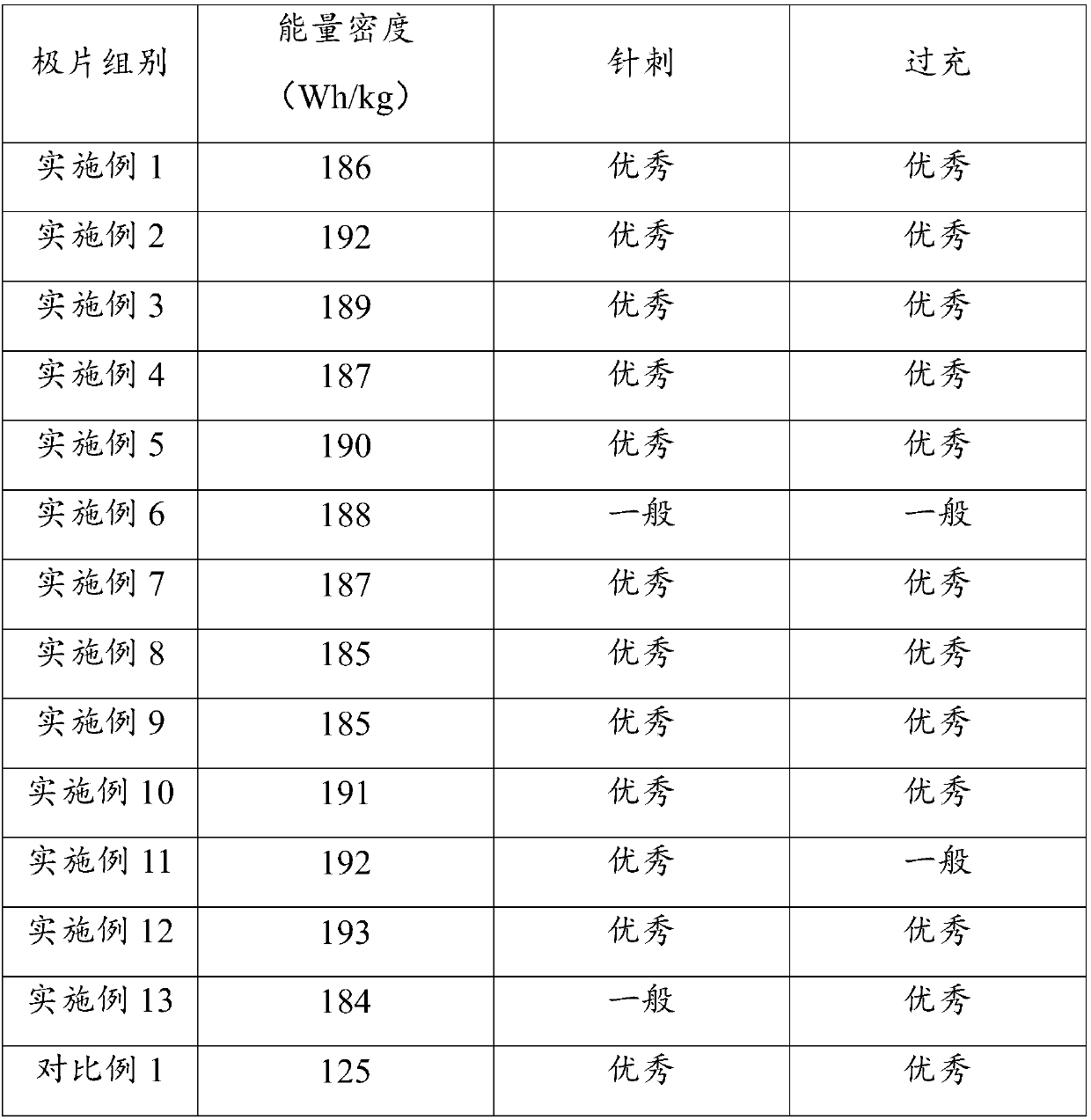

Embodiment 1

[0088] A lithium ion battery positive electrode material, the lithium ion battery positive electrode material is composed of the following components in mass percentage: positive electrode active material 97.5%, conductive agent 0.8% and binder 1.7%;

[0089] The positive electrode active material is composed of the following components in mass percentage: 10% lithium manganese iron phosphate and 90% nickel cobalt lithium manganese oxide;

[0090] Among them, lithium manganese iron phosphate is LiMn 0.6 Fe 0.4 PO 4 , D50 is 20μm, specific surface area is 30m 2 / g;

[0091] Lithium nickel cobalt manganate is Li(Ni 0.6 co 0.2 mn 0.2 )O 2 , D50 is 10μm, specific surface area is 0.3m 2 / g;

[0092] The conductive agent is graphene;

[0093] The binder is a combination of polyvinyl fluoride and polyvinylidene fluoride.

Embodiment 2

[0095] A lithium ion battery positive electrode material, the lithium ion battery positive electrode material is composed of the following components in mass percentage: positive electrode active material 98%, conductive agent 0.5% and binder 1.5%;

[0096] The positive electrode active material is composed of the following components in mass percentage: 50% of lithium manganese iron phosphate and 50% of nickel-cobalt lithium manganese oxide;

[0097] Among them, lithium manganese iron phosphate is LiMn 0.7 Fe 0.3 PO 4 , D50 is 30μm, specific surface area is 20m 2 / g;

[0098] Lithium nickel cobalt manganate is Li(Ni 0.8 co 0.1 mn 0.1 )O 2 , D50 is 15μm, specific surface area is 0.1m 2 / g;

[0099] The conductive agent is graphene;

[0100] The binder is polytetrafluoroethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com