Positive electrode active material and preparation method thereof as well as lithium ion battery

A technology of positive electrode active materials and composite materials, which is applied in the field of positive electrode active materials and their preparation and lithium-ion batteries, and can solve problems such as low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also provides a method for preparing the positive electrode active material as described above, the steps comprising:

[0019] S1. Will Li 2 MoO 4 , molybdenum oxide and carbon source mixed;

[0020] S2, high temperature sintering and cooling in reducing atmosphere to prepare Li 2 MoO 3 and molybdenum carbide.

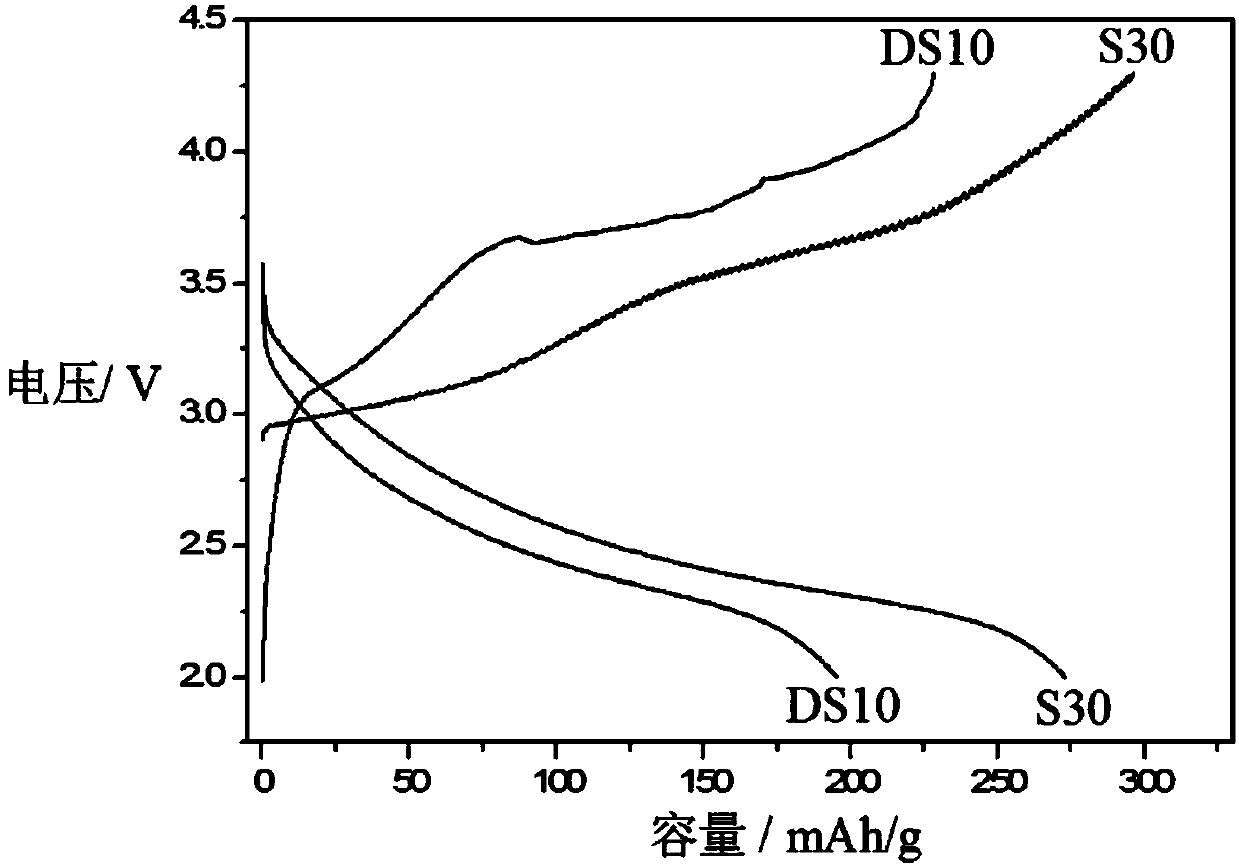

[0021] Carbon source and molybdenum oxide in Li 2 MoO 3 The particle surface reacts, so the Mo 2 C formed on Li 2 MoO 3 on the surface of the particles, forming Mo 2 C and Li 2 MoO 3 Particles in close contact, forming a complete or partial coating. At the same time Mo 2 C can also block adjacent Li 2 MoO 3 particles, preventing Li 2 MoO 3 The particle grows up, which is conducive to the deintercalation of lithium ions. In the synthesis of Li 2 MoO 3 Molybdenum carbide (Mo 2 C), which can make the mixing of materials more uniform, make the contact of materials closer, and effectively reduce Li 2 MoO 3 The particle size...

Embodiment 1

[0033] Will Li 2 MoO 4 , molybdenum trioxide and glucose were mixed according to the mass ratio of 100:1.3:0.27, and placed in a stirring ball mill for mixing and grinding for 8 hours; the precursor prepared by fully mixing and grinding was placed in a corundum crucible; the crucible was put into a tube furnace, and the Into 10%H 2 / Ar mixed gas, heating from room temperature at a heating rate of 5 °C / min, heating up to 600 °C for 10 h, then raising the temperature to 850 °C for 20 h, and then naturally cooling to room temperature to obtain Mo 2 Li with a C content of 1 wt% 2 MoO 3 / Mo 2 C composite, labeled S1. The average particle size of the prepared S1 is 5 μm.

Embodiment 2

[0035] Will Li 2 MoO 4 , molybdenum dioxide, and glucose were mixed according to a mass ratio of 100:2.3:0.55, placed in a stirring ball mill, added ethanol, and wet mixed and ground for 6 hours; the precursor prepared by fully mixing and grinding was dried and placed in a corundum crucible; The crucible was placed in a tube furnace and fed with 10% H 2 / Ar mixed gas, heating from room temperature at a heating rate of 5°C / min, raising the temperature to 650°C for 10 hours, then raising the temperature to 900°C for 10 hours, and then naturally cooling to room temperature to obtain Mo 2 Li with a C content of 2wt% 2 MoO 3 / Mo 2 C composite, labeled S2. The average particle size of the prepared S2 is 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com