A kind of cotton meal delint, dephenol method

A cottonseed and delinting technology, applied in food processing, animal husbandry, additional food elements, etc., can solve the problems of high production cost, chemical reagent residue, long duration, etc., to save production cost, improve palatability, and easily The effect of absorption and digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

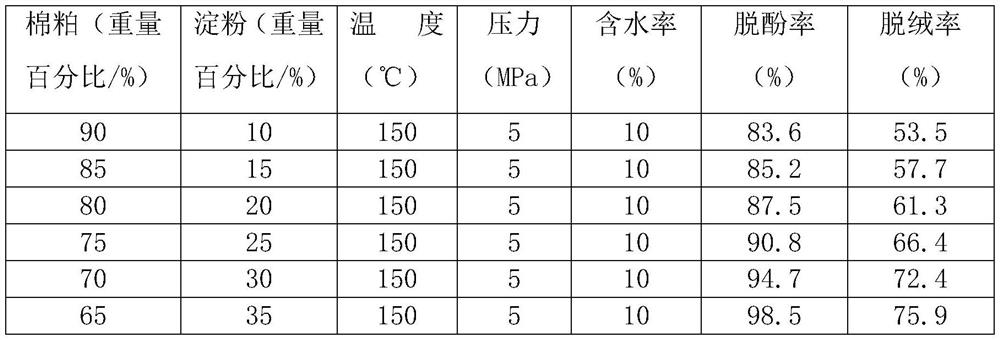

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: mainly comprise the following steps:

[0023] (1), material mixing: choose cornstarch and cotton meal to mix, the weight percentage of described cotton meal is 90%, and the balance is starch, then add water fully after starch and cotton meal total solid material weight ratio is 8%. Mix to make the starch fully adhere to the cotton meal;

[0024] (2) Extrusion and expansion: Extrude and expand the mixed material in step (1) under the conditions of a temperature of 150° C., a pressure of 6 MPa, and a screw speed of 320 r / min.

Embodiment 2

[0025] Embodiment 2: mainly comprise the following steps:

[0026] (1), material mixing: choose cornstarch and cotton meal to mix, the weight percentage of described cotton meal is 85%, and the balance is starch, is then fully carried out after adding water by starch and cotton meal total solid material weight ratio of 9%. Mix to make the starch fully adhere to the cotton meal;

[0027] (2) Extrusion and expansion: Extrude and expand the mixed material in step (1) under the conditions of a temperature of 155° C., a pressure of 5.5 MPa, and a screw speed of 326 r / min.

Embodiment 3

[0028] Embodiment 3: mainly comprise the following steps:

[0029] (1), material mixing: choose cornstarch and cotton meal to mix, the weight percentage of described cotton meal is 80%, and the balance is starch, then add water fully after starch and cotton meal total solid material weight ratio is 10%. Mix to make the starch fully adhere to the cotton meal;

[0030] (2) Extrusion and expansion: under the conditions of temperature of 140°C, pressure of 4.5 MPa, and screw speed of 332 r / min, the mixed material in step (1) was subjected to extrusion and expansion treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com