Method for preparing stable soybean protein-sterol granules through combining heat treatment with high-pressure micro jet treatment

A high-pressure micro-fluidics and soybean protein technology, applied in the field of deep processing of grain by-products, can solve the problems of poor protein thermal stability, reduce food shelf life, flocculation, etc., achieve good resolubility, improve shelf life, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing functional soybean protein-sterol particles by heat treatment combined with high-pressure micro-fluidic treatment, the steps are as follows:

[0055] (1) Disperse soybean protein in deionized water at a material-to-liquid ratio of 0.8:10 (w / v, g / mL), adjust the pH to 7.0, stir at room temperature 15-30°C for 2 hours, and heat in a water bath at 90°C for 30 minutes. Rapidly cool down to room temperature, and pass high-pressure micro-jet once under a pressure of 100Mpa to obtain the desired protein solution;

[0056] (2) Disperse the dry phytosterol powder in absolute ethanol at 0.02:1 (w / v, g / mL), and stir in a water bath to obtain the required sterol-ethanol solution;

[0057] (3) Add the sterol-ethanol solution to the casein solution at a volume ratio of 0.5:10 under the condition of a high-speed shearing machine at a rate of 13000rpm, and perform ultrasonic treatment after mixing for 4 minutes (power 240W, time 10min, interval 50%) ), then the ...

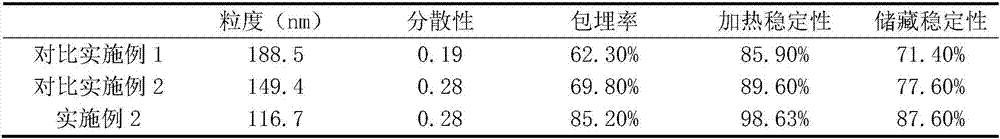

Embodiment 2

[0065] A method for preparing functional soybean protein-sterol particles by heat treatment combined with high-pressure micro-fluidic treatment, the steps are as follows:

[0066] (1) Disperse soybean protein in deionized water at a material-to-liquid ratio of 1:10 (w / v, g / mL), adjust the pH to 7.0, stir at room temperature 15-30°C for 2 hours, and place in an autoclaved pot at 120°C Heating for 20 minutes, cooling down to room temperature rapidly, and passing high-pressure micro-jet once under a pressure of 100Mpa to obtain the desired soybean protein solution;

[0067] (2) Disperse the dry phytosterol powder in absolute ethanol at 0.02:1 (w / v, g / mL), and stir in a water bath to obtain the required sterol-ethanol solution;

[0068] (3) Add the sterol-ethanol solution to the casein solution at a volume ratio of 0.5:10 under the condition of a high-speed shearing machine at a rate of 13000rpm, and perform ultrasonic treatment after mixing for 4 minutes (power 240W, time 10min, ...

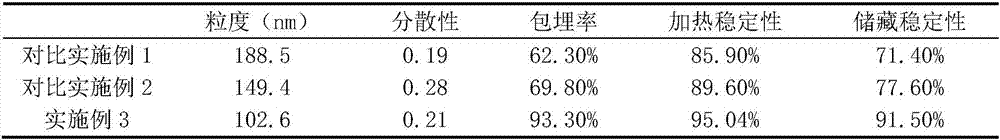

Embodiment 3

[0075] A method for preparing functional soybean protein-sterol particles by heat treatment combined with high-pressure micro-fluidic treatment, the steps are as follows:

[0076] (1) Disperse soybean protein in deionized water at a material-to-liquid ratio of 1:10 (w / v, g / mL), adjust the pH to 7.0, stir at room temperature 15-30°C for 2 hours, and heat in a water bath at 120°C for 20 minutes. Rapidly cool to room temperature, and pass high-pressure micro-jet once at a pressure of 120Mpa to obtain the desired soybean protein solution;

[0077] (2) Disperse the dry phytosterol powder in absolute ethanol at 0.02:1 (w / v, g / mL), and stir in a water bath to obtain the required sterol-ethanol solution;

[0078] (3) Add the sterol-ethanol solution to the casein solution at a volume ratio of 0.5:10 under the condition of a high-speed shearing machine at a rate of 13000rpm, and perform ultrasonic treatment after mixing for 4 minutes (power 240W, time 10min, interval 50%) ), then the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com