Method for preparing high-visible light activity nitrogen doped N-TiO2

A technology of visible light and active nitrogen, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of expensive electron beam irradiation equipment and limited development, achieve high visible light catalytic activity, reduce Excellent production cost and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

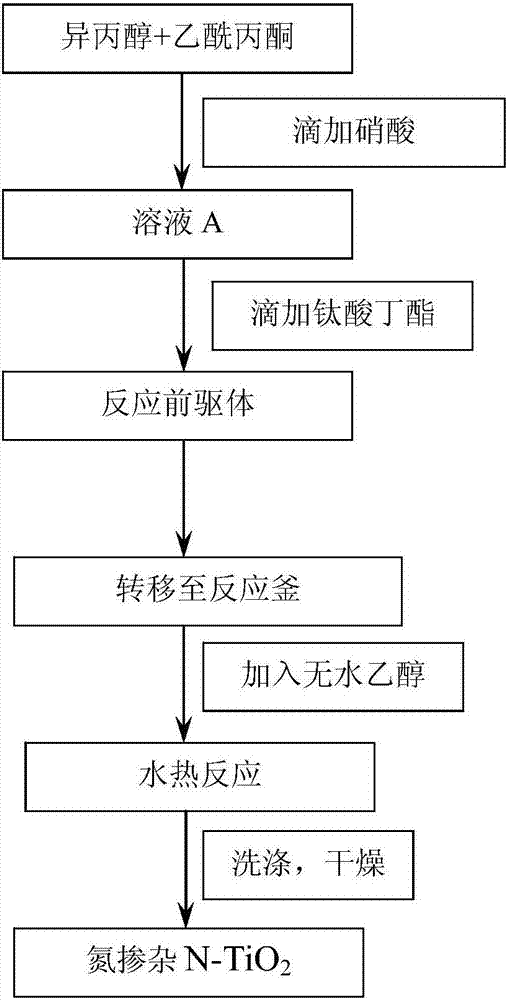

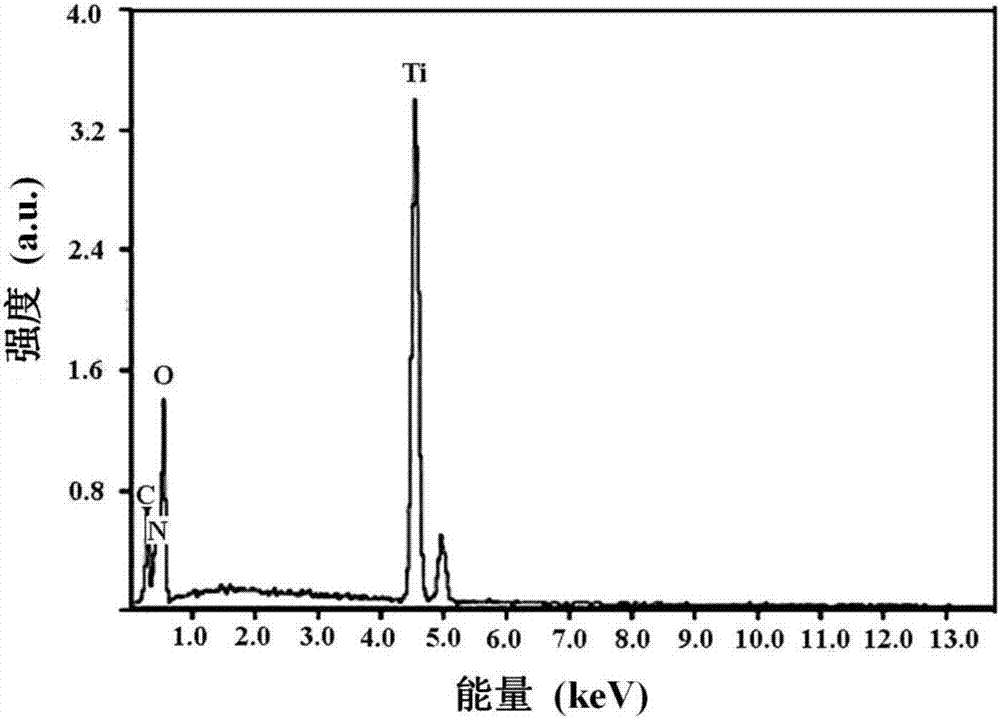

[0030] Such as figure 1 Shown, the nitrogen-doped N-TiO of the present embodiment 2 The preparation process comprises the following steps: measure 60mL of a mixed solution of isopropanol and acetylacetone at a volume ratio of 1:1 with a graduated cylinder and place it in a dry beaker, then measure 3mL of nitric acid with a mass fraction of 68% and dropwise into The above mixed solution of isopropanol and acetylacetone was stirred for 15 min to obtain solution A. While stirring, 6 mL of butyl titanate was added dropwise to solution A at a titration rate of 5 mL / min with a pipette gun, and stirring was continued for 15 min to obtain a reaction precursor. Transfer the reaction precursor to the reaction kettle, add absolute ethanol to make the filling degree 70%; seal the reactants, put the reaction kettle in an oven at 180° C., and react for 18 hours. After cooling, the product was centrifugally washed with deionized water until neutral, and dried in an oven at 80 °C to obtain ...

Embodiment 2

[0038] Use a graduated cylinder to measure 50 mL of a mixed solution of isopropanol and acetylacetone at a volume ratio of 1:1 and place it in a dry beaker, then use a pipette to measure 1.5 mL of nitric acid with a mass fraction of 68% and add it dropwise to the above-mentioned isopropanol and acetylacetone. The mixed solution of acetone was stirred for 10 min to obtain solution A. While stirring, add 4 mL of butyl titanate dropwise to solution A at a titration rate of 5 mL / min with a pipette gun, and continue stirring for 15 min to obtain a reaction precursor. Transfer the reaction precursor to the reaction kettle, add absolute ethanol to make the filling degree 80%; seal the reactant, put the reaction kettle in an oven at 160° C., and react for 16 hours. After cooling, the product was centrifugally washed with deionized water until neutral, and dried in an oven at 80 °C to obtain nitrogen-doped N-TiO 2 .

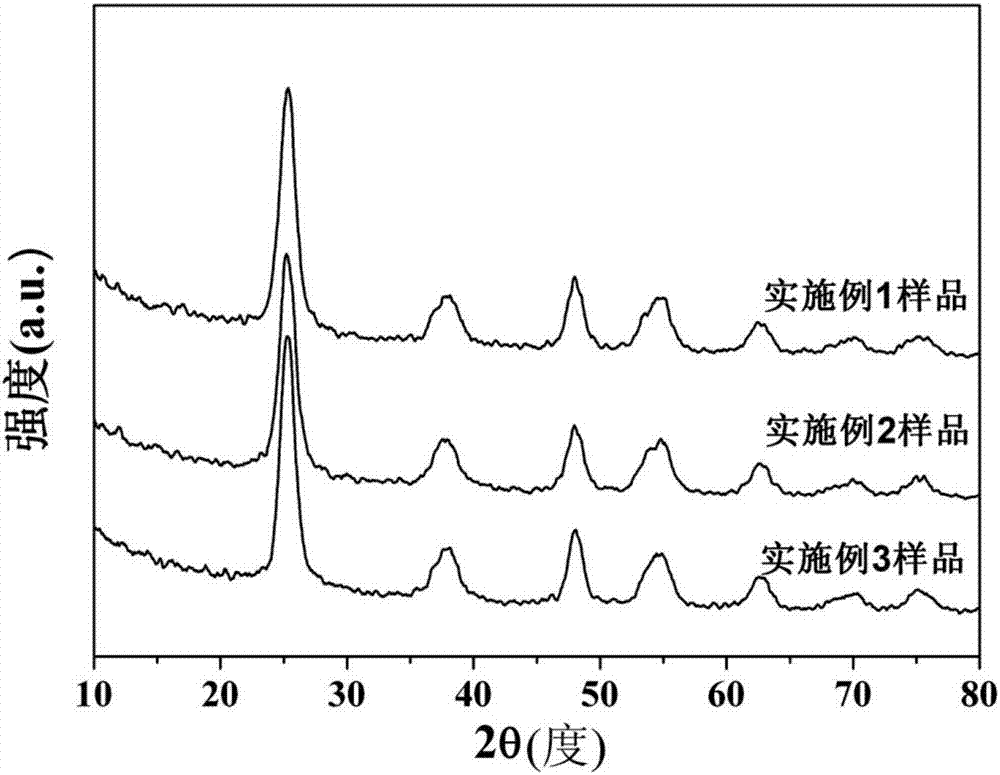

[0039] figure 2 It also shows that the nitrogen-doped N-TiO prep...

Embodiment 3

[0042] Measure 55mL of the mixed solution of isopropanol and acetylacetone with a volume ratio of 1:1 with a graduated cylinder and place it in a dry beaker, then use a pipette to measure 2mL of nitric acid with a mass fraction of 68% and add it dropwise to the above isopropanol and acetylacetone The mixed solution was stirred for 10 min to obtain solution A. While stirring, 5 mL of butyl titanate was added dropwise to solution A at a titration rate of 5 mL / min with a pipette gun, and the stirring was continued for 15 min to obtain a reaction precursor. Transfer the reaction precursor to the reaction kettle, add absolute ethanol to make the filling degree 80%; seal the reactant, put the reaction kettle in an oven at 160° C., and react for 16 hours. After cooling, the product was centrifugally washed with deionized water until neutral, and dried in an oven at 80°C to obtain nitrogen-doped N-TiO 2 .

[0043] figure 2 It also shows that the nitrogen-doped N-TiO prepared in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com