Method for preparing activated carbon by utilizing sludge

A technology for preparing activated carbon and sludge, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as equipment corrosion and environmental pollution, and achieve the effects of improving performance, reducing pollution, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

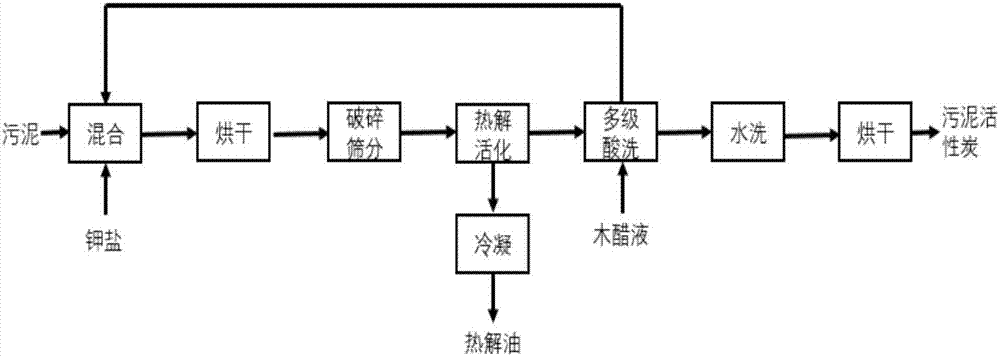

Image

Examples

Embodiment 1

[0027] A method for preparing activated carbon from sludge, specifically comprising the following steps:

[0028] S1 A certain amount of dewatered sludge and a certain amount of activator are transported to the screw mixing device through the feeder, and the activator is impregnated with dewatered sludge. The mass ratio of sludge to potassium-containing activator is 2:1, and the potassium-containing activator The active ingredient is potassium acetate, the potassium ion concentration is 2mol / L, and the immersion time is 8h.

[0029] S2 Transport the uniformly mixed sludge in step S1 to the screw drying device. The moisture content of the dried sludge is about 10%, and then the dried sludge is crushed and screened by a crusher, and the particles The particle size is 1.5mm.

[0030] S3 flows the screened particles into the spiral carbonization activation device for pyrolysis activation reaction. The pyrolysis temperature is about 800°C and the pyrolysis time is 1.5h. During the...

Embodiment 2

[0035] A method for preparing activated carbon from sludge, specifically comprising the following steps:

[0036] S1 A certain amount of dewatered sludge and a certain amount of activator are transported to the screw mixing device through the feeder, and the activator is impregnated with dewatered sludge. The mass ratio of sludge to potassium-containing activator is 0.5:1, and the potassium-containing activator The active ingredient is potassium acetate, the potassium ion concentration is 3mol / L, and the immersion time is 10h.

[0037] S2 Transport the uniformly mixed sludge in step S1 to the screw drying device. The moisture content of the dried sludge is about 10%, and then the dried sludge is crushed and screened by a crusher, and the particles The particle size is 0.5mm.

[0038] The particles screened by S3 flow into the spiral carbonization activation device for pyrolysis activation reaction. The pyrolysis temperature is about 750°C and the pyrolysis time is 2 hours. Du...

Embodiment 3

[0043] A method for preparing activated carbon from sludge, specifically comprising the following steps:

[0044] S1 A certain amount of dewatered sludge and a certain amount of activator are transported to the screw mixing device through the feeder, and the activator is impregnated with dewatered sludge. The mass ratio of sludge to potassium-containing activator is 3:1, and the potassium-containing activator The active ingredient is potassium acetate, the potassium ion concentration is 1mol / L, and the immersion time is 12h.

[0045] S2 Transport the uniformly mixed sludge in step S1 to the screw drying device. The moisture content of the dried sludge is within 10%. After the dried sludge is crushed and screened by a crusher, the particles The diameter is 1.5mm.

[0046] S3 flows the screened particles into the spiral carbonization activation device for pyrolysis activation reaction. The pyrolysis temperature is about 850°C, and the pyrolysis time is 1h. During the pyrolysis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com