Sodium chloride spherocrystals and preparation method thereof

A technology of sodium chloride and spherulites, which is applied in the field of salt crystallization to achieve the effect of reducing the agglomeration rate and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

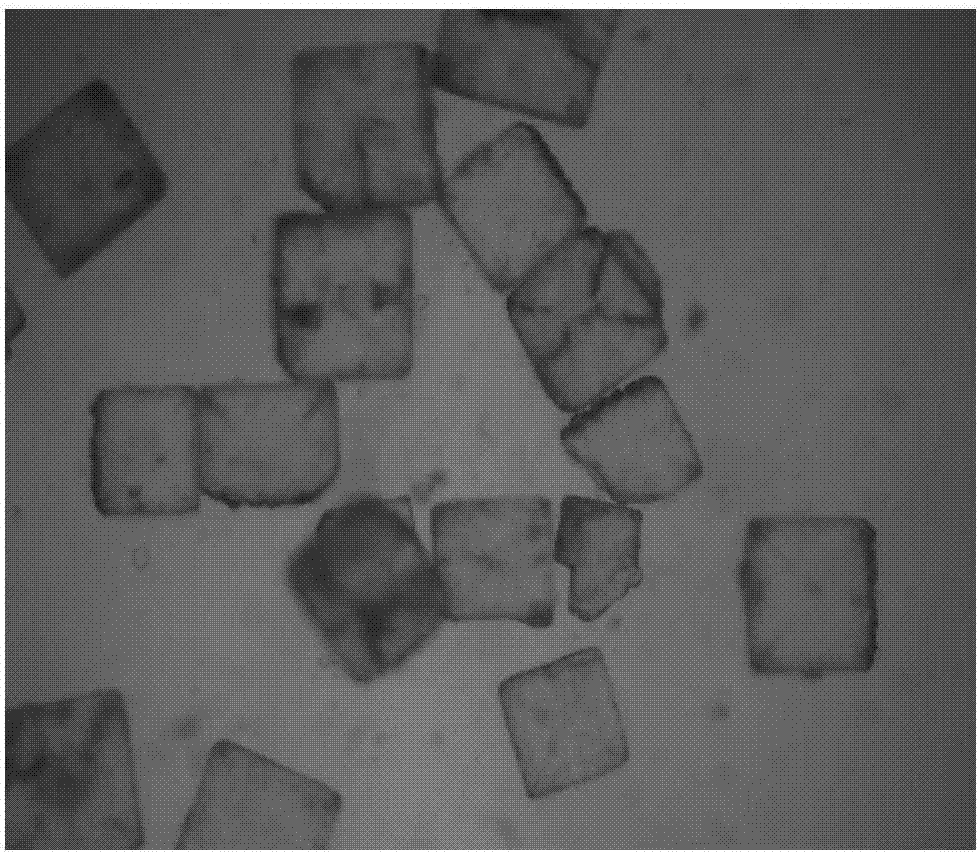

Embodiment 1

[0038] Add 60.0g of sodium chloride to 200mL (the density of water is 1g / mL, the mass ratio of sodium chloride to water is 0.3:1) deionized water, start stirring, the stirring rate is 600rpm, and the system temperature is 80°C , adopt the decompression evaporation crystallization method, the evaporation rate of water is 10mL / hr (that is, 5% / hr of water volume), evaporate 140mL of water (solid-liquid ratio is 45%), and then continue to stir for 4h. Then filter, and dry the filter cake at 40°C under normal pressure for 12 hours to constant weight to obtain the sodium chloride spherulite product. The mass fraction of crystals within the particle size range of 0.25-0.6mm is 71.22%, and the mass fraction of crystals below 0.25mm is 0.81%. The roundness value of the product is 0.88, the caking rate is 25%, and the angle of repose is 19.2°.

Embodiment 2

[0040] Add 70.0g of sodium chloride into 200mL (that is, the mass ratio of sodium chloride to water is 0.35:1) of deionized water, start stirring, the stirring rate is 500rpm, the system temperature is 60°C, and the method of vacuum evaporation and crystallization is adopted. The evaporation rate is 20mL / hr (ie 10% / hr of water volume). 120 mL of water was evaporated (37% solid-to-liquid ratio), and stirring was continued for 6 h. Then filter, and dry the filter cake at 50°C and normal pressure for 10 hours to constant weight to obtain the sodium chloride spherulite product. The mass fraction of crystals within the particle size range of 0.25-0.6mm is 75.13%, and the mass fraction of crystals below 0.25mm is 0.94%. The roundness value of the product was 0.90, the caking rate was 29%, and the angle of repose was 19.9°.

Embodiment 3

[0042] Add 70.0g of sodium chloride to 200mL (that is, the mass ratio of sodium chloride and water is 0.35:1) of deionized water, start stirring, the stirring rate is 500rpm, the system temperature is 65°C, and the vacuum evaporation crystallization method is adopted. The evaporation rate is 10mL / hr (ie 5% / hr of water volume). 130 mL of water was evaporated (45% solid-to-liquid ratio), and stirring was continued for 6 h. Then filter, and dry the filter cake at 70°C under normal pressure for 8 hours to constant weight to obtain the sodium chloride spherulite product. The mass fraction of crystals within the particle size range of 0.25-0.6mm is 72.36%, and the mass fraction of crystals below 0.25mm is 0.70%. The roundness value of the product was 0.89, the caking rate was 26%, and the angle of repose was 20.2°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com