Bismuth oxybromide visible-light-induced photocatalyst and preparation method thereof

A catalyst and visible light technology, applied in the field of new semiconductor photocatalytic materials, can solve the problems of complex method and difficult operation control, and achieve the effects of good purity, simple operation and high photogenerated carrier separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 1.2g of glucose to 50mL of ethylene glycol and stir at room temperature for 15min, then add 0.485g of Bi(NO 3 ) 3 .5H 2 O continue to stir, stir well and then add 0.06g KBr, and continue to stir for 12h to form a clear solution.

[0019] The above mixed solution was subjected to microwave reaction, the microwave power was 400W, and the reaction time was 4min. After the reaction, a gray-yellow precipitate was obtained, which was centrifuged, washed three times with deionized water and absolute ethanol, and the obtained solid was placed at 60°C Dry in an oven for 12 hours to obtain the precursor.

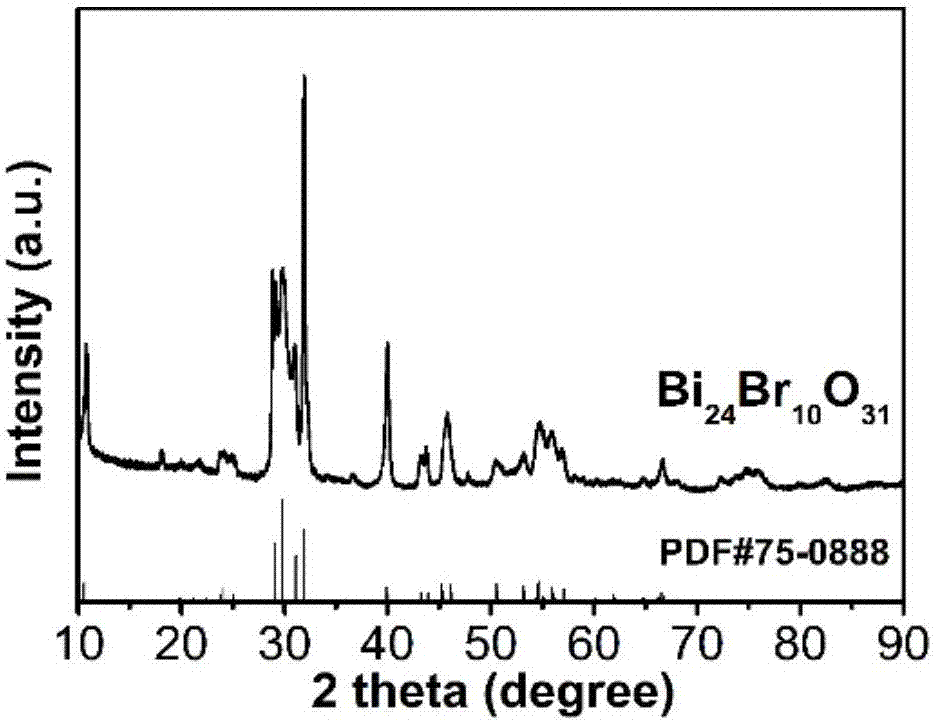

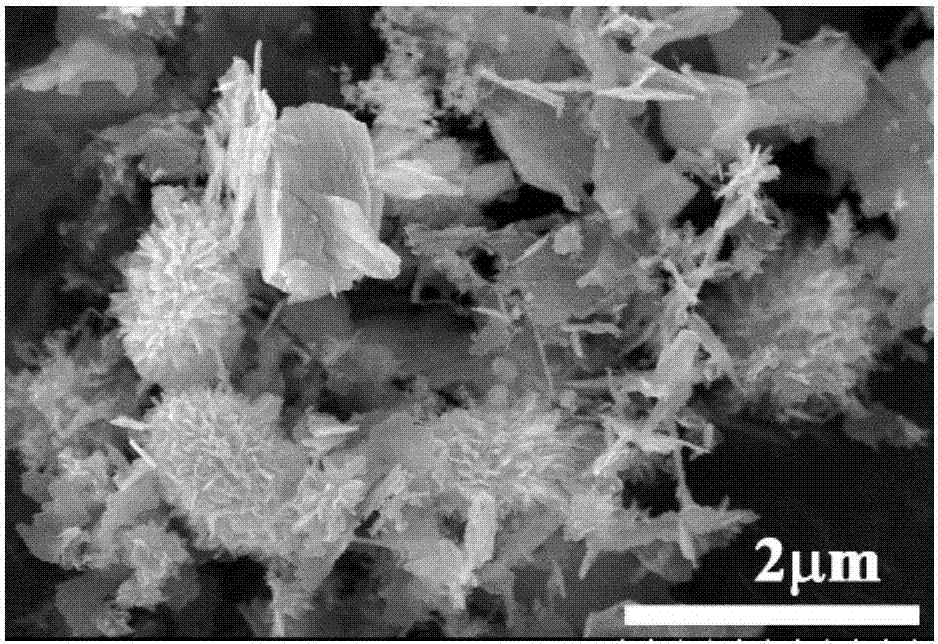

[0020] Bi 24 Br 10 o 31 catalyst of light. Its XRD pattern is as figure 1 As shown, Bi 24 Br 10 o 31 The diffraction peaks are consistent with the standard card, with high purity and good crystallinity. Bi 24 Br 10 o 31 The SEM pattern such as figure 2 As shown, it is in the shape of nano flower balls, and some of them collapse and break after calcination. ...

Embodiment 2

[0022] Add 2.4g glucose to 100mL ethylene glycol and stir at room temperature for 15min, then add 0.485gBi(NO 3 ) 3 .5H 2 O continue to stir, stir well and then add 0.06g KBr, and continue to stir for 48h to form a clear solution.

[0023] The above mixed solution was subjected to microwave reaction, the microwave power was 800W, and the reaction time was 3min. After the reaction, a gray-yellow precipitate was obtained, which was centrifuged, washed three times with deionized water and absolute ethanol, and the obtained solid was placed at 60°C. Dry in an oven for 12 hours to obtain the precursor.

[0024] Weigh 300 mg of the precursor and calcinate it in a muffle furnace at 400 °C for 4 hours to obtain Bi 24 Br 10 o 31 catalyst of light.

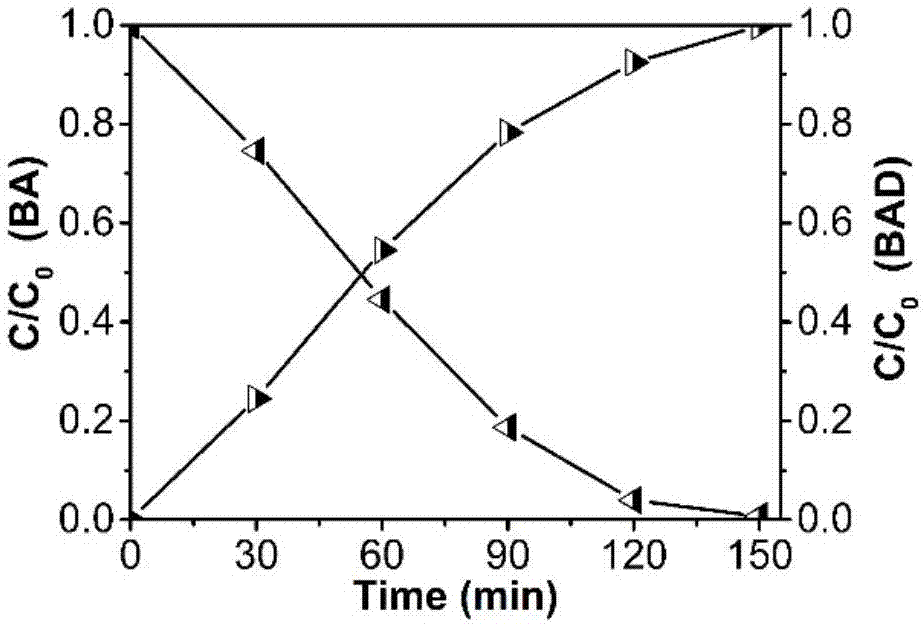

[0025] Using the Bi of the embodiment of the present invention 24 Br 10 o 31 In the experiment of catalytic conversion of benzyl alcohol into benzaldehyde under visible light irradiation, the selectivity of benzyl alcohol into benz...

Embodiment 3

[0027] Add 0.6g glucose to 100mL ethylene glycol and stir at room temperature for 15min, then add 0.485gBi(NO 3 ) 3 .5H 2 O continue to stir, stir well and then add 0.06g KBr, and continue to stir for 6h to form a clear solution.

[0028] The above mixed solution was subjected to microwave reaction, the microwave power was 200W, and the reaction time was 10min. After the reaction, a gray-yellow precipitate was obtained, which was centrifuged, washed three times with deionized water and absolute ethanol, and the obtained solid was placed at 60°C Dry in an oven for 12 hours to obtain the precursor.

[0029] Weigh 300 mg of precursor and calcinate in a muffle furnace at 500 °C for 2 hours to obtain Bi 24 Br 10 o 31 catalyst of light.

[0030] Using the Bi of the embodiment of the present invention 24 Br 10 o 31 In the experiment of catalytic conversion of benzyl alcohol into benzaldehyde under visible light irradiation, the selectivity of benzyl alcohol into benzaldehyde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com