Preparation method for melamine cyanurate and application thereof

A technology of melamine cyanurate and melamine, applied in the field of polymer chemistry, can solve the problems of high production cost, limited application, low production efficiency, etc., and achieve the effect of reducing the viscosity of the system and increasing the solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 solid content 20%

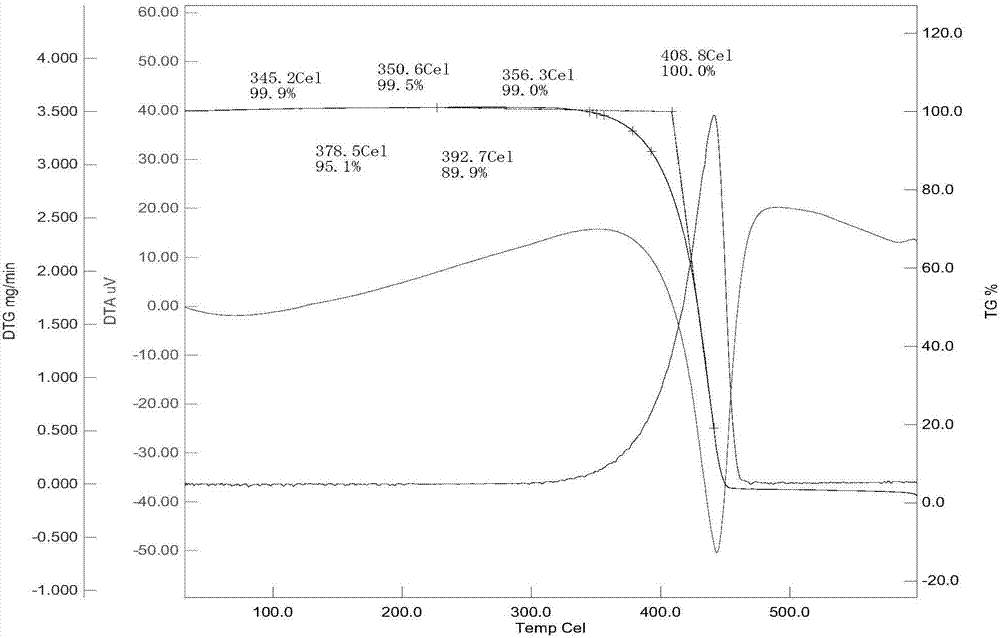

[0026] Add 36L of water and 9g of sustained-release agent into a 50L reactor, stir at 60°C for 10min, add 4.6kg of cyanuric acid (purity 99.5%), add 4.4kg of melamine (purity 99.8%) after heating up to 90°C, and continue to heat up to 95°C , insulation reaction 1h. The slurry was filtered to separate the material and the liquid, the reaction mother liquor was transported to the reactor for reuse, the filter cake was sent to the drier for drying and crushing, and 8.9 kg of melamine cyanurate product with a purity of 99.7% was obtained, and the decomposition temperature was 356.3°C.

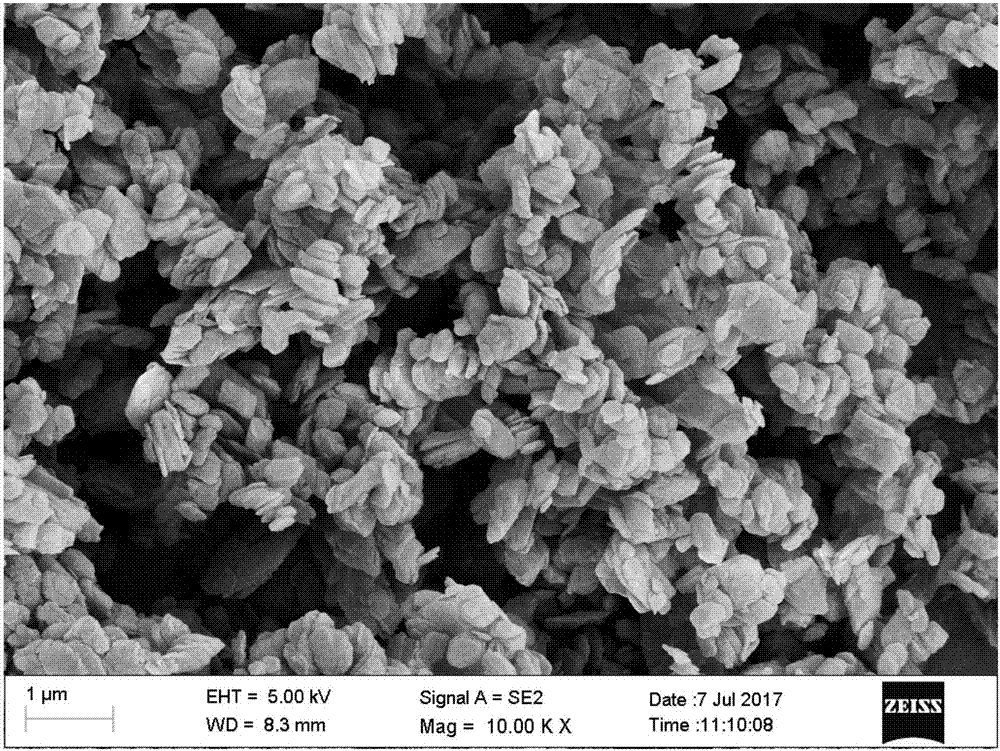

[0027] figure 1 Shown is the SEM collection of illustrative plates of the melamine cyanurate prepared by the present embodiment, by figure 1 It can be seen that the obtained product is in the form of flaky crystals.

[0028] figure 2 Shown is the TGA collection of illustrative plates of the melamine cyanurate prepared by the present embodiment, by figu...

Embodiment 2

[0029] Embodiment 2 solid content 20%

[0030] Add 36L of water and 45g of sustained-release agent into a 50L reactor, stir at 70°C for 10min, add 4.6kg of cyanuric acid (purity 99.5%), add 4.4kg of melamine (purity 99.8%) after heating up to 90°C, and continue to heat up to 98°C , heat preservation reaction 48min. The slurry is filtered to separate the material and liquid, the reaction mother liquor is transported to the reactor for reuse, and the filter cake is sent to a drier for drying and crushing to obtain 8.7 kg of melamine cyanurate product with a purity of 99.5%, which is shown by a scanning electron microscope image. The melamine cyanurate prepared in this example is in the form of flaky crystals; the TGA diagram shows that the decomposition temperature is 350.6°C.

Embodiment 3

[0031] Embodiment 3 solid content 20%

[0032] Add 36L of water and 62g of sustained-release agent into a 50L reactor, stir at 75°C for 10min, add 4.6kg of cyanuric acid (purity 99.5%), add 4.4kg of melamine (purity 99.8%) after heating up to 90°C, and continue to heat up to 96°C , heat preservation reaction 52min. The slurry is filtered to separate the material and liquid, the reaction mother liquor is transported to the reactor for reuse, and the filter cake is sent to a drier for drying and crushing to obtain 8.8 kg of melamine cyanurate product with a purity of 99.6%, which is shown by a scanning electron microscope image. The melamine cyanurate prepared in this example is in the form of flaky crystals; the TGA diagram shows that the decomposition temperature is 352.2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com