Adhesive resin composition and self-adhesive protective film

A resin composition and adhesive technology, applied in the direction of polymer adhesive additives, film/sheet adhesives, adhesives, etc., can solve the problems of protective film unwinding force, easy to produce adhesion, difficult to operate, etc. To achieve the effect of easier unwinding, less precipitation, and less transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

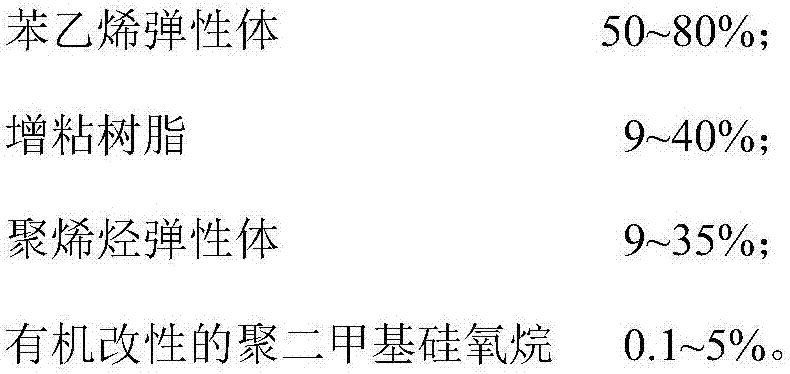

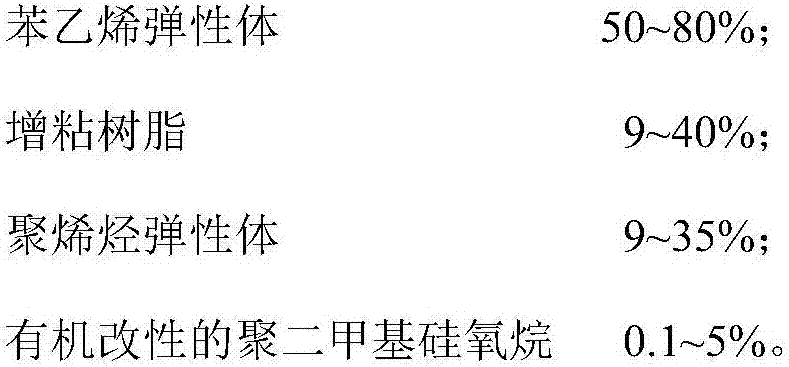

[0038] Adhesive resin composition is the styrene elastomer G1657 (Kraton company) of 50% by weight, the tackifying resin U130 (An Yuan Chemical) of 40% by weight, and the polyolefin elastomer 3980FL of 9% by weight (ExxonMobil) and 1% by weight organomodified polydimethylsiloxane TEGOMER 2342 (Evonik Degussa).

[0039] The self-adhesive protective film of the present invention is composed of an adhesive layer, an intermediate layer and a surface layer to form a three-layer cast extrusion composite form, wherein: the intermediate layer is a homopolypropylene resin extruded by an extruder; the surface layer is made of propylene resin. - It is produced by melt extrusion of ethylene block copolymer and low-density polyethylene resin; the adhesive layer is formed by casting and extruding as a single component after the above-mentioned adhesive resin mixture is blended and granulated by twin-screws.

Embodiment 2

[0041] Adhesive resin composition is the styrene elastomer G1657 (Kraton company) of 80% by weight, the tackifying resin U130 (Anyuan Chemical) of 9% by weight, and the polyolefin elastomer 3980 of 10.9% by weight (ExxonMobil) and 0.1% by weight organomodified polydimethylsiloxane TEGOMER 2342 (Evonik Degussa).

[0042] The self-adhesive protective film of the present invention is composed of an adhesive layer, an intermediate layer and a surface layer to form a three-layer cast extrusion composite form, wherein: the intermediate layer is a homopolypropylene resin extruded by an extruder; the surface layer is made of propylene resin. - It is produced by melt extrusion of ethylene block copolymer and low-density polyethylene resin; the adhesive layer is formed by casting and extruding as a single component after the above-mentioned adhesive resin mixture is blended and granulated by twin-screws.

Embodiment 3

[0044] Adhesive resin composition is the styrene elastomer G1657 (Kraton company) of 50% by weight, the tackifying resin U130 (Anyuan Chemical) of 14.9% by weight, and the polyolefin elastomer 3980FL of 35% by weight (ExxonMobil) and 0.1% by weight organomodified polydimethylsiloxane TEGOMER 2342 (Evonik Degussa).

[0045] The self-adhesive protective film of the present invention is composed of an adhesive layer, an intermediate layer and a surface layer to form a three-layer cast extrusion composite form, wherein: the intermediate layer is a homopolypropylene resin extruded by an extruder; the surface layer is made of propylene resin. - It is produced by melt extrusion of ethylene block copolymer and low-density polyethylene resin; the adhesive layer is formed by casting and extruding as a single component after the above-mentioned adhesive resin mixture is blended and granulated by twin-screws.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com