DOT6 boric acid ester type braking fluid

A borate ester and brake fluid technology, which is applied in the field of DOT6 borate brake fluid, can solve the problems of increasing the steric hindrance of borate ester, failing to meet the anti-oxidation and corrosion resistance, and failing to meet technical requirements, etc., to achieve Effect of Good Low Temperature Kinematic Viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 1.5T reactor, add 125kg of polyethylene glycol ethyl ether in sequence; triethylene glycol methyl ether borate: 855kg; 6-methyl-2-mercaptobenzothiazole: 1.5kg; methylbenzotriazepam Azole: 1.0kg; N-methyl monoethanolamine: 8kg; Antioxidant 1010: 0.9kg; 2-ethylhexyl acrylate: 1.2kg; 4,4'-butylene bis(6-tert-butyl m-cresol ): 0.4kg; methylparaben: 0.2kg; propylparaben: 0.2kg; dodecenylsuccinic acid (T746): 0.4kg; alkalinity regulator dodecahydrodiphenylamine: 6.2kg; After continuing to stir for 6 hours, it can be filtered and distributed through a 0.1um filter.

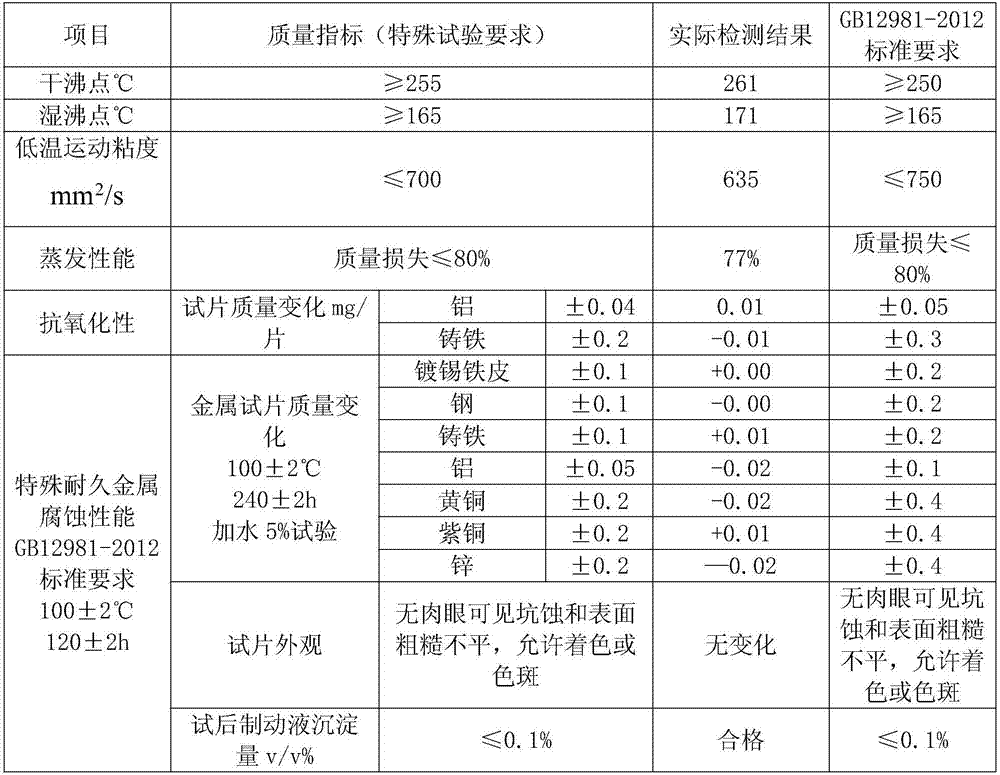

[0023] The test results of the main technical indicators are as follows (according to the requirements of the special durable metal corrosion test):

[0024]

[0025]It can be seen from the above table that DOT6 borate brake fluid has a high dry and wet boiling point that meets the requirements of GB12981-2012, and has good low-temperature kinematic viscosity. The additive formula used can meet the specia...

Embodiment 2

[0027] Add 80kg of polyethylene glycol methyl ether in sequence to a 1.5T reactor; triethylene glycol methyl ether borate: 900kg; 6-methyl-2-mercaptobenzothiazole: 1.0kg; methylbenzotri Azole: 1.0kg; N-methyl monoethanolamine: 8kg; Antioxidant 1010: 0.8kg; 2-ethylhexyl acrylate: 1.2kg; Phenol): 0.3kg; methylparaben: 0.1kg; propylparaben: 0.1kg; dodecenylsuccinic acid (T746): 0.2kg, alkalinity regulator dodecahydrodiphenylamine: 7.3kg ; After continuing to stir for 6 hours, it can be filtered and distributed through a 0.1um filter.

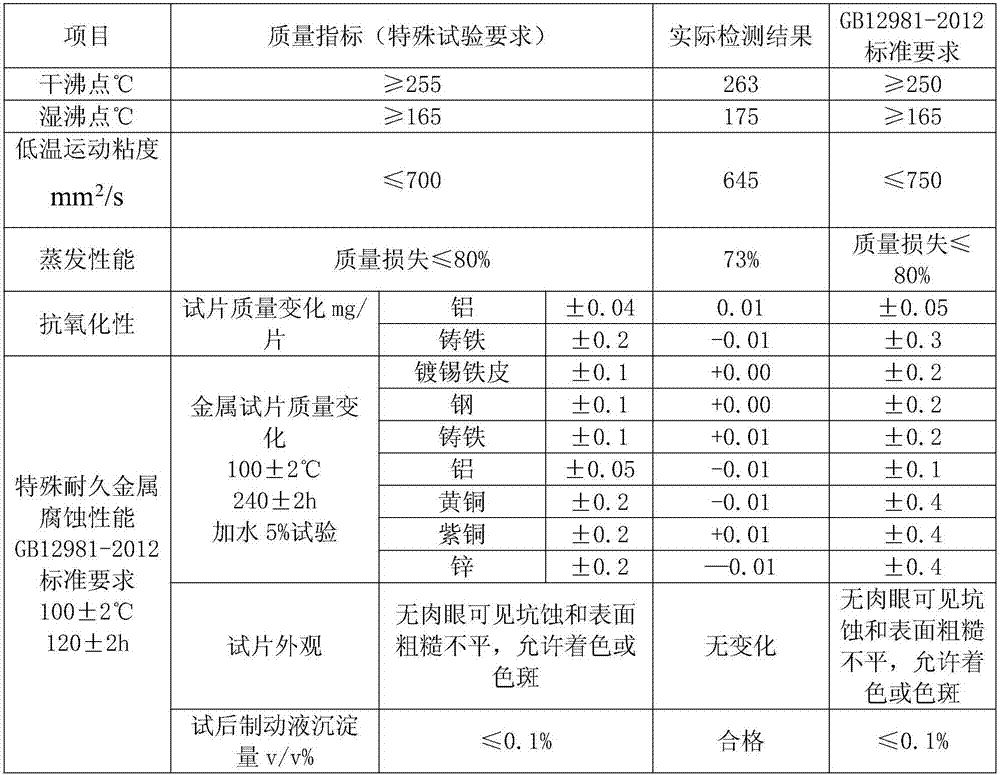

[0028] The test results of the main technical indicators are as follows (according to the requirements of the special durable metal corrosion test):

[0029]

[0030] It can be seen from the above table that the preferred DOT6 borate brake fluid has a high dry and wet boiling point that meets the requirements of GB12981-2012, and has good low-temperature kinematic viscosity, moderate formula cost, and excellent performance indicators .

Embodiment 3

[0032] In the 1.5T reactor, add 150kg of polyethylene glycol methyl ether in sequence; triethylene glycol methyl ether borate: 835kg; 6-methyl-2-mercaptobenzothiazole: 0.8kg; methylbenzotri Azole: 0.8kg; N-methyl monoethanolamine: 5kg; Antioxidant 1010: 0.7kg; 2-ethylhexyl acrylate: 1.0kg; phenol): 0.3kg; methylparaben: 0.1kg; propylparaben: 0.2kg; dodecenylsuccinic acid (T746): 0.3kg; alkalinity regulator dodecahydrodiphenylamine: 5.8kg ; After continuing to stir for 6 hours, it can be filtered and distributed through a 0.1um filter.

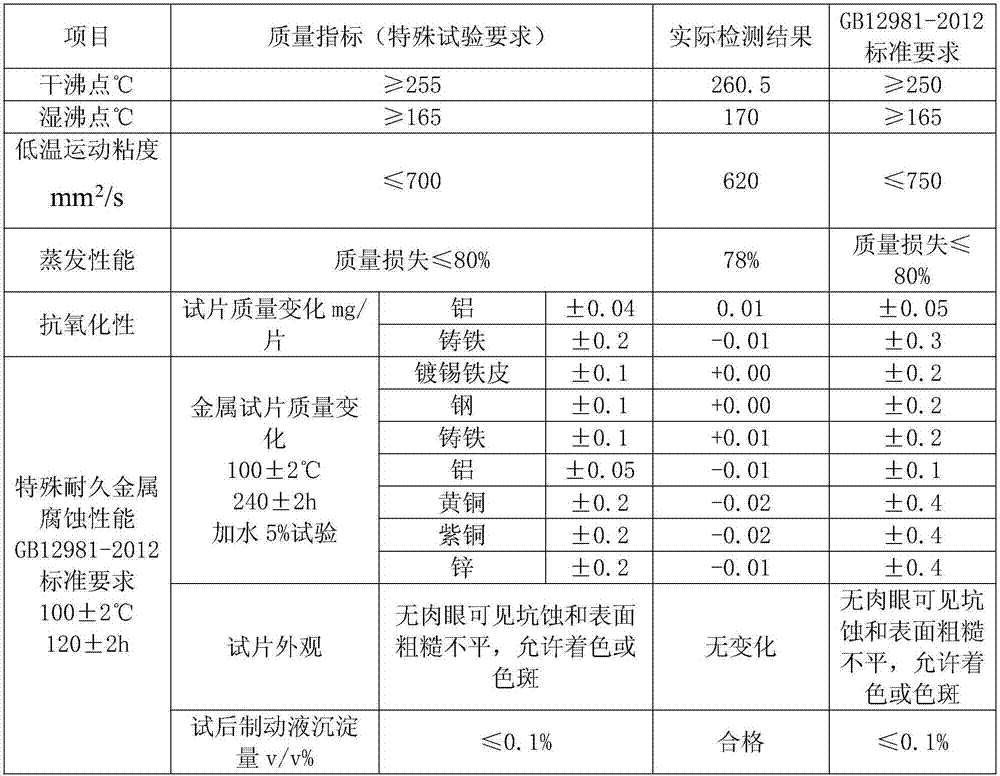

[0033] The test results of the main technical indicators are as follows (according to the requirements of the special durable metal corrosion test):

[0034]

[0035] It can be seen from the above table that the DOT6 borate brake fluid with this formula technology meets the requirements of GB12981-2012, but the dry and wet boiling points are slightly lower, and the low-temperature kinematic viscosity is good. The additive formula used can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com