Mixed treatment technology of copper and lead anode slime

A technology of lead anode slime and copper anode slime, applied in selenium/tellurium compounds, inorganic chemistry, non-metallic elements, etc., can solve problems such as process dispersion, large amount of waste water, and difficult recovery of valuable metals, and achieve easy operation and solution The effect of large amount of wastewater and easy control of process indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

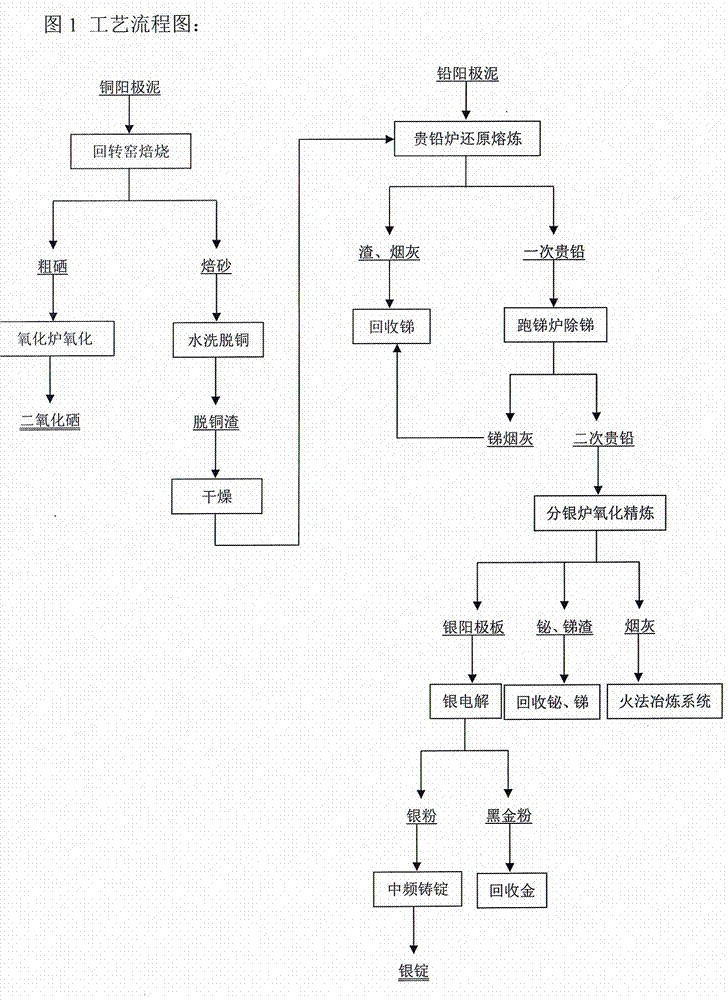

Image

Examples

Embodiment 1

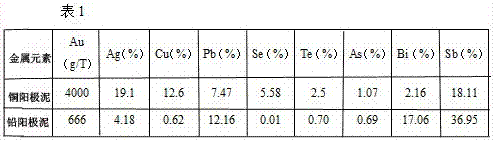

[0015] Embodiment 1: Copper anode slime and lead anode slime are taken as examples containing the following elements, and their element contents are shown in Table 1:

[0016]

[0017] Take the following process steps:

[0018] a. Sulfation roasting of copper anode slime: according to the mass ratio of acid to material 0.8:1, add 800kg of sulfuric acid, 1000kg of copper anode slime dry basis, slurry for 1h, add 50kg of dilute sulfuric acid solution with 5% weight of copper anode slime (of which sulfuric acid 8.06kg, water 41.94kg), enter the rotary kiln roasting after pulping for 5 hours, control the temperature in the first zone to 570°C, the temperature in the second zone to 590°C, the temperature in the third zone to 610°C, and the temperature in the fourth zone to 630°C to obtain coarse selenium and calcined sand;

[0019] b. Crude selenium oxidation furnace oxidation, control temperature 480 ℃, oxygen flow rate 24L / min, obtain selenium dioxide product;

[0020] c. Cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com