Refining method of o-hydroxybenzonitrile

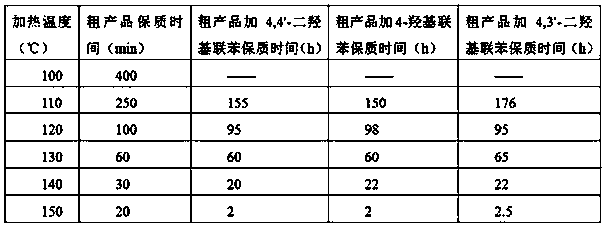

A technology of o-hydroxybenzonitrile and refining method, which is applied in the purification/separation of carboxylic acid nitrile, organic chemistry, etc., can solve the problems of unsuitable o-hydroxybenzonitrile scale application, easy deterioration of cyano groups, etc., and prolong the thermal stability time , Improve stability and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for purifying o-hydroxybenzonitrile of the present invention, comprising the steps:

[0032] (1) Put 1800g (80%, 12.1mol) of o-hydroxybenzonitrile crude product in a 3000ml constant temperature funnel, heat up to 95°C, the crude product is completely melted into a liquid state, and 0.18g of 4,4'- Dihydroxybiphenyl, mixed uniformly to prepare distillation bottom material.

[0033] (2) Turn on the vacuum pump of the molecular distillation apparatus, the vacuum degree in the distillation apparatus is 5 mbar, the distillation heating temperature of the distillation apparatus is set to 120 °C, the cooling temperature of the condenser is 95 °C, and the light fraction receiver is kept warm to 95 °C; Turn on the feed pump, The distillation bottom material was pumped into the molecular distillation apparatus, the feed rate was 10ml / min, and the distillation was completed after 180min, and the obtained light fraction was put into the flake machine for flakes to obtain 13...

Embodiment 2

[0035] A method for purifying o-hydroxybenzonitrile of the present invention, comprising the steps:

[0036] (1) 1800g (90%, 13.6mol) o-hydroxybenzonitrile crude product was placed in a 3000ml constant temperature funnel, heated to 95°C, the crude product was completely melted into a liquid state, and 1.8g of 4,4'- Dihydroxybiphenyl, mixed uniformly to prepare distillation bottom material.

[0037] (2) Turn on the vacuum pump of the molecular distillation apparatus, the vacuum degree in the distillation apparatus is 8 mbar, set the heating temperature of the distillation apparatus to 130 °C, the cooling temperature of the condenser to be 100 °C, and the heat preservation of the light fraction receiver to be 100 °C; The distillation bottom material was pumped into a molecular distillation apparatus, the feed rate was 40ml / min, and the distillation was completed after 45min, and the obtained light fraction was put into a flaker for flakes, to obtain 1511g of white flaky o-hydrox...

Embodiment 3

[0039] A method for purifying o-hydroxybenzonitrile of the present invention, comprising the steps:

[0040](1) 1800g (80%, 12.1mol) o-hydroxybenzonitrile crude product was placed in a 3000ml constant temperature funnel, heated to 95°C, the crude product was completely melted into a liquid state, and 0.18g of 4,3'- Dihydroxybiphenyl, mixed uniformly to prepare distillation bottom material.

[0041] (2) Turn on the vacuum pump of the molecular distillation apparatus, the vacuum degree in the distillation apparatus is 5 mbar, set the heating temperature of the distillation apparatus to 120 °C, the cooling temperature of the condenser to be 95 °C, and the heat preservation of the light fraction receiver to be 95 °C; The distillation bottom material was pumped into the molecular distillation apparatus, the feed rate was 20ml / min, and the distillation was completed after 90min, and the obtained light fractions were put into the flake machine for flakes, to obtain 1311g of white fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com