Preparation method of mushroom-shaped metal column array surface with stratum structure

A technology of metal surface and metal pillars, which is applied in the field of preparing the surface of mushroom-shaped metal pillar arrays with a hierarchical structure, can solve the problems of poor mechanical strength, short service life, and inability to meet long-term use, and achieve strong durability and high mechanical strength , Expand the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

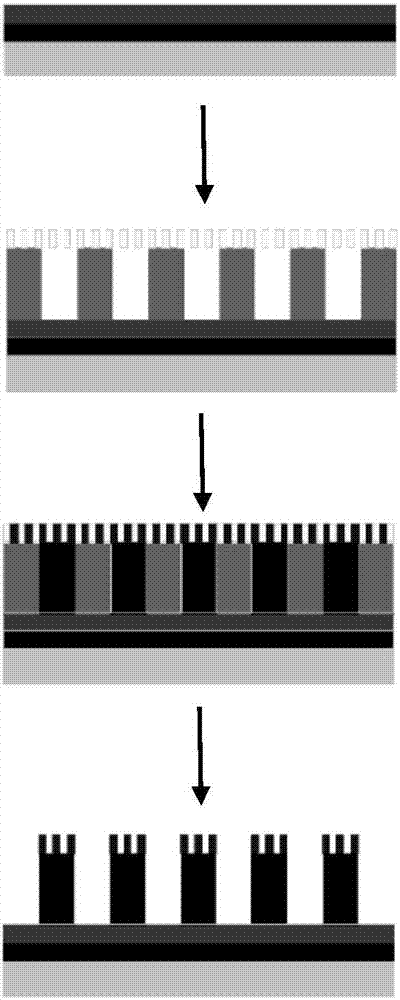

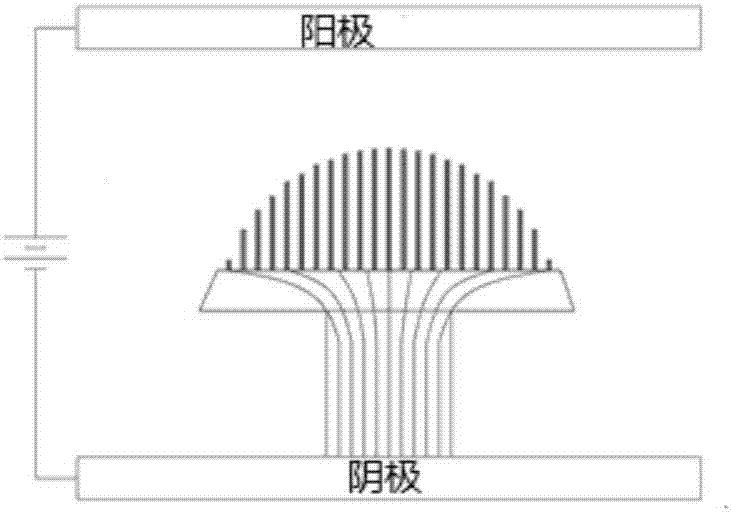

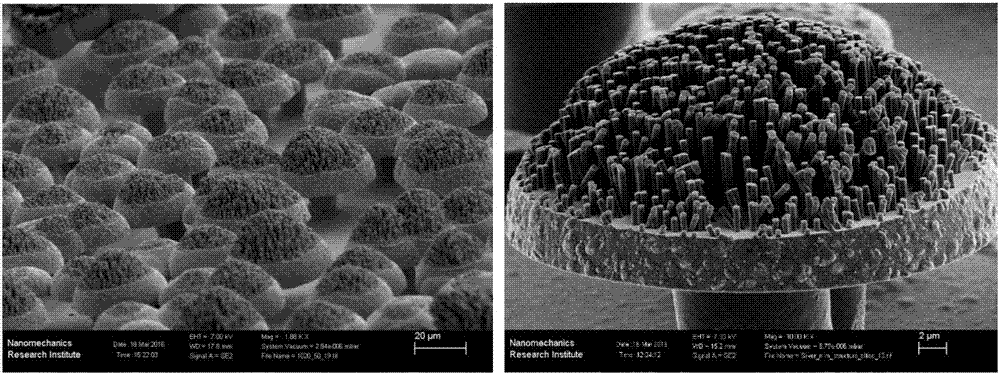

[0033] A 100nm thick titanium film and a 20nm thick gold film were sequentially deposited on a single crystal silicon wafer, and a polycarbonate porous membrane with a pore size of 12 μm (thickness 14 μm) and a polycarbonate porous membrane with a pore size of 400 nm (thickness 20 μm) were sequentially deposited. Covered on the surface of the silicon substrate. Take an appropriate amount of silver electroplating solution and add it to the electroplating tank, immerse the anode platinum electrode and the reference electrode in the electroplating solution, use the workpiece as the cathode, and use the double-layer polycarbonate film as the mask, adopt the constant current silver electroplating process, the current is 10mA, The electroplating time is 35 minutes, and an array of mushroom-shaped silver metal pillars with a hierarchical structure is electroplated and grown on the surface. After the set time is reached, the constant current meter is turned off, and the plated samples...

Embodiment 2

[0035] A 100nm thick titanium film and a 20nm thick gold film were sequentially deposited on a single crystal silicon wafer, and a polycarbonate porous membrane with a pore diameter of 5 μm (thickness 10 μm) and a polycarbonate porous membrane with a pore diameter of 500 nm (thickness 10 μm) were sequentially deposited. Covered on the surface of the silicon substrate. Take an appropriate amount of copper electroplating solution and add it to the electroplating tank, immerse the anode platinum electrode and the reference electrode in the electroplating solution, use the workpiece as the cathode, and use the double-layer polycarbonate film as the mask, adopt the constant potential copper electroplating process, and the current is 19mA, The electroplating time is 20 minutes, and an array of mushroom-shaped copper metal pillars with a hierarchical structure is electroplated and grown on the surface. After the set time is reached, the constant current meter is turned off, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com