Phase-change material based heat radiator

A technology of phase change materials and radiators, which is applied in the fields of instrumentation, cooling/ventilation/heating transformation, electrical digital data processing, etc., can solve the problems of heat pipe corrosion, increase the production process, and destructible properties, so as to prolong the service life and reduce the Good effect of heat absorption burden and heat dissipation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

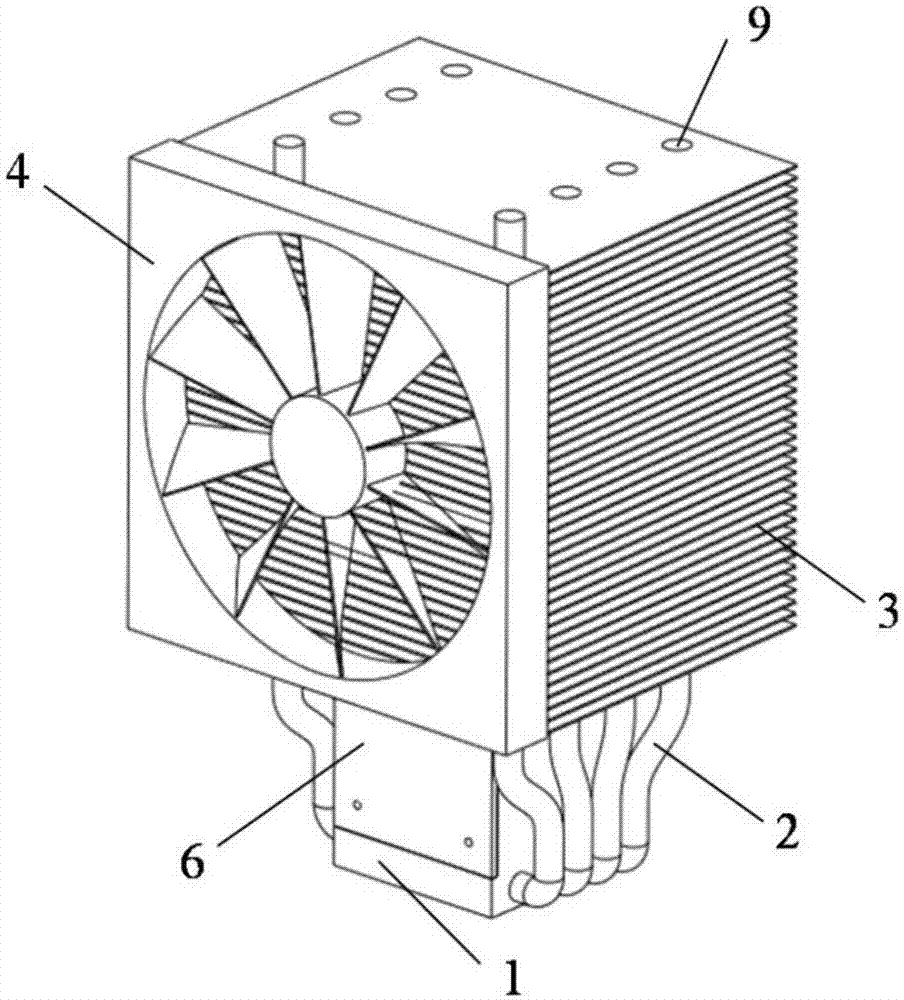

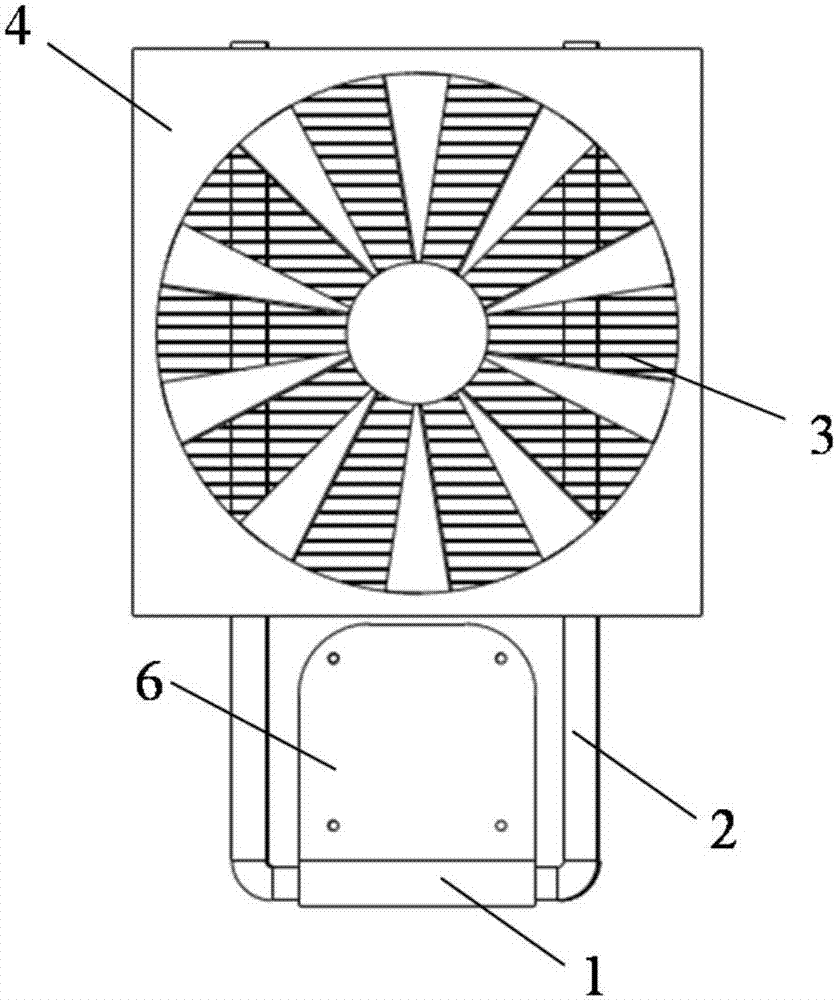

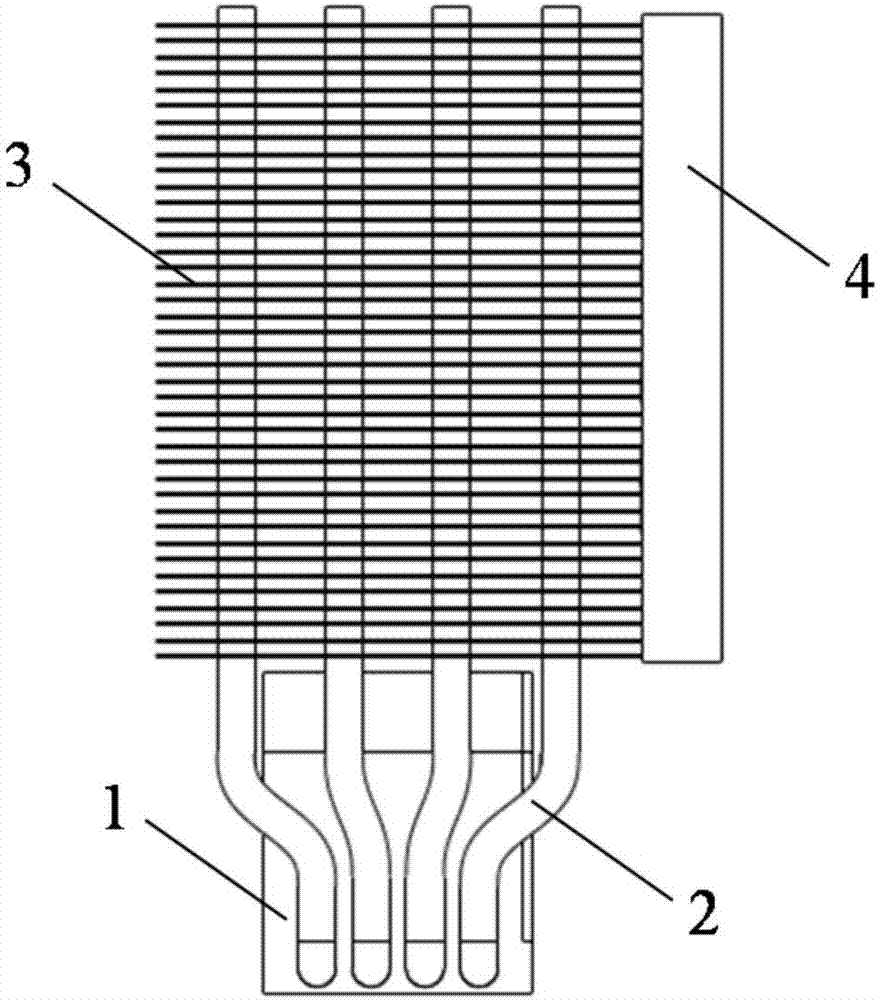

[0050] Manufacture a CPU heat sink based on phase change material, in which the phase change device acts as a heat sink and is placed on the CPU electronic components. 4 heat pipes with a diameter of 7mm pass through the through holes of the housing of the phase change device, 40 heat dissipation fins are welded and sleeved on the 4 heat pipes, and a fan with a diameter of 120mm is installed on one side of the heat dissipation fins.

[0051] The length of the phase change device is 50 mm, the width is 50 mm, and the height is 60 mm; the inner cavity has a diameter of 37 mm and a length of 46 mm, and the inner cavity is filled with a thermally conductive phase change material. The thermally conductive phase change material is composed of a 60° C. phase change material and foamed copper, wherein the foamed copper accounts for 5% of the thermally conductive phase change material by volume.

[0052] The housing of the phase change device is made of aluminum alloy, the heat pipe is made...

Embodiment 2

[0055] Embodiment 2 Embodiment 1 is basically the same, and the differences are shown in Table 1.

Embodiment 3

[0057] Example 3 is basically the same as Example 1, and the differences are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com