Titanium dioxide doped carbon nitride and its preparation method and application

A technology of titanium dioxide and carbon nitride, applied in structural parts, electrical components, battery pack parts, etc., can solve problems such as poor cycle stability and low coulombic efficiency of lithium-sulfur batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

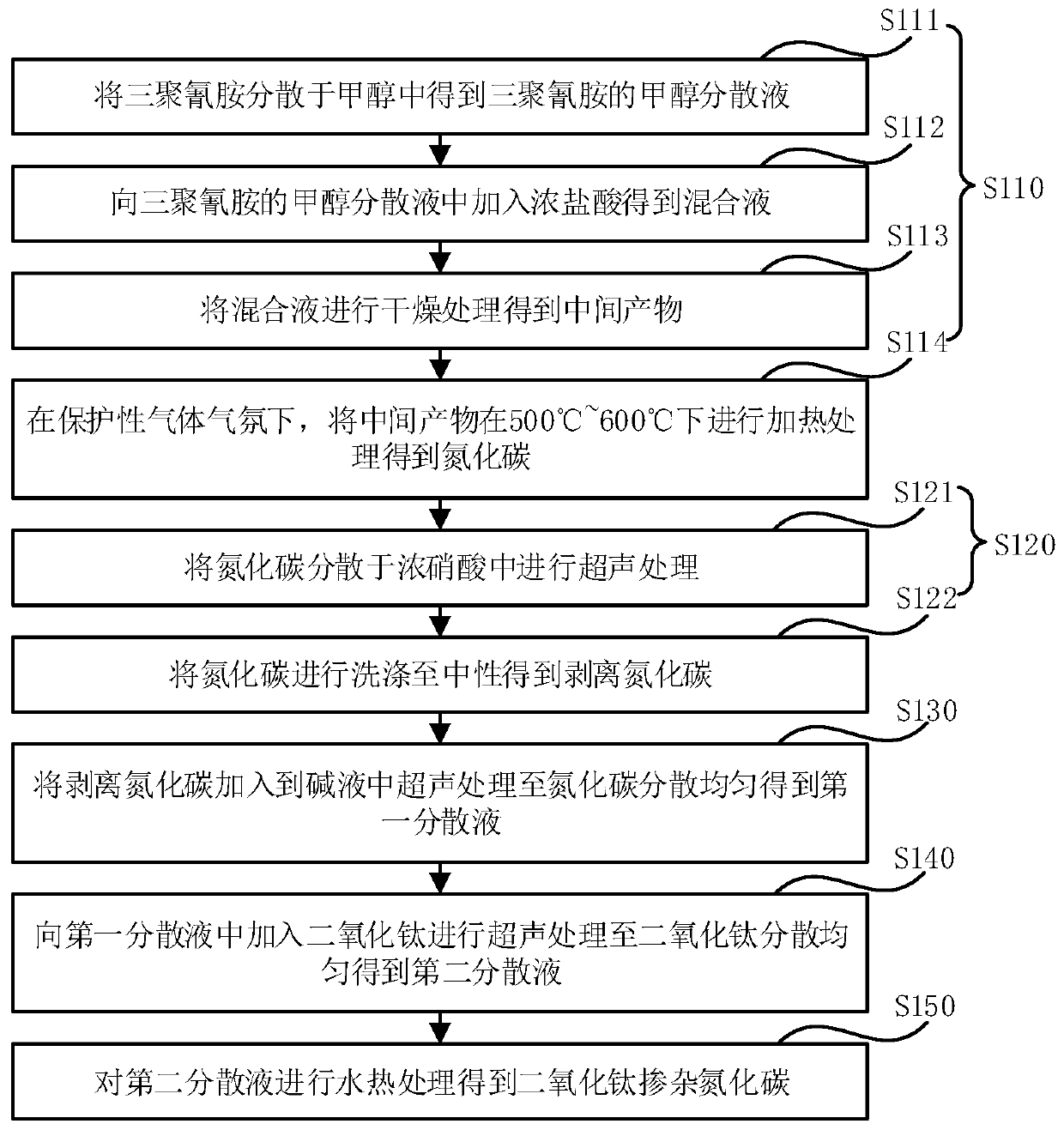

[0037] see figure 1 , the preparation method of titanium dioxide doped carbon nitride of an embodiment, comprises the following steps:

[0038] S110, preparing carbon nitride.

[0039] In one of the embodiments, the step of preparing carbon nitride specifically includes the following steps:

[0040] S111. Dispersing melamine in methanol to obtain a methanol dispersion of melamine.

[0041] In one embodiment, the mass ratio of melamine to methanol is 1:5˜1:20.

[0042] In one embodiment, the melamine is added into the methanol and then stirred, the time of the stirring is 1h-4h, and the rotation speed of the stirring is 80r / min-200r / min.

[0043] S112, adding concentrated hydrochloric acid to the methanol dispersion of melamine to obtain a mixed solution.

[0044] In one embodiment, the mass concentration of the concentrated hydrochloric acid is 20%-37%.

[0045] In one embodiment, the dosage ratio of melamine to concentrated hydrochloric acid is 1g:1mL˜1g:20mL.

[0046] ...

Embodiment 1

[0113] Disperse 5 g of melamine in 75 g of methanol and stir for 1 h to obtain a methanol dispersion of melamine, then add 5 mL of concentrated hydrochloric acid with a mass concentration of 37% to the methanol dispersion of melamine, and continue stirring for 1 h to obtain a mixed solution. The mixed solution was placed in a vacuum drying oven, methanol and the like were evaporated to dryness to obtain an intermediate product, and then the intermediate product was heat-treated at 600° C. under a nitrogen atmosphere to obtain carbon nitride. Add 1g of carbon nitride into 50mL of concentrated nitric acid with a mass concentration of 95%, and perform ultrasonic treatment, wherein the power of ultrasonic treatment is 100W, and the time of ultrasonic treatment is 15h; the carbon nitride is washed alternately with water and alcohol until Neutral to get stripped carbon nitride, the specific surface area of stripped carbon nitride is 160m 2 / g.

[0114] Add 0.2 g of stripped carbo...

Embodiment 2

[0117] Disperse 10 g of melamine in 100 g of methanol and stir for 1 h to obtain a methanol dispersion of melamine, then add 200 mL of concentrated hydrochloric acid with a mass concentration of 20% to the methanol dispersion of melamine, and continue stirring for 4 h to obtain a mixed solution. The mixed solution was placed in a vacuum drying oven, methanol, etc. were evaporated to dryness to obtain an intermediate product, and then the intermediate product was heat-treated at 550° C. under a nitrogen atmosphere to obtain a carbon nitride primary product. Add 1g of carbon nitride primary product into 50mL of concentrated nitric acid with a mass concentration of 95%, and perform ultrasonic treatment, wherein the power of ultrasonic treatment is 100W, and the time of ultrasonic treatment is 10h; The product is washed to neutrality to obtain carbon nitride, and the specific surface area of carbon nitride is 180m 2 / g.

[0118] Add 0.2 g of stripped carbon nitride to 120 mL of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com