Cation-anion codoped and modified layered lithium-rich anode material and preparation method thereof

A lithium-rich cathode material, anion and cation technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of high discharge platform, poor rate performance of lithium-rich cathode materials, low initial Coulombic efficiency, etc., and achieve stability Material structure, improvement of first-time efficiency, safe and effective effect of battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

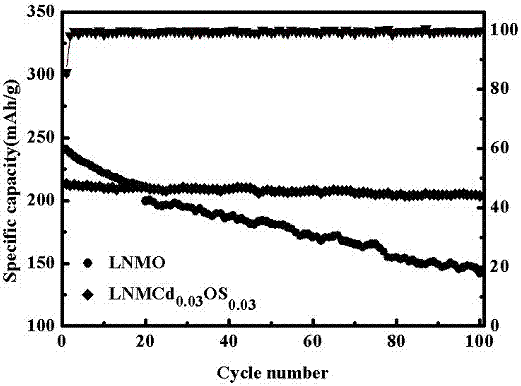

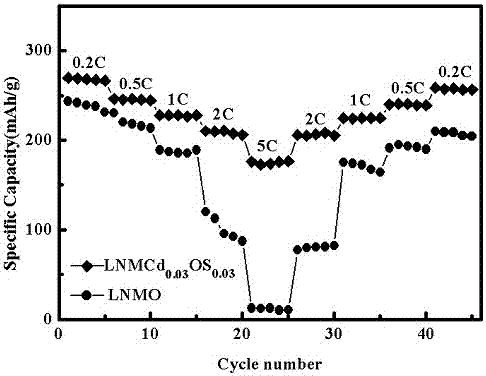

Embodiment 1

[0025] An anion and cation Cd 2+ , S 2- The preparation method of the co-doped lithium-rich positive electrode material, the specific embodiment is as follows:

[0026] A. Weigh quantitative nickel sulfate (NiSO 4 )6.6 g, manganese sulfate (MnSO 4 ) 12.7g was dissolved in deionized water to obtain a nickel-manganese sulfate solution, wherein the Ni:Mn molar ratio in the nickel-cobalt-manganese sulfate solution was 0.2:0.6;

[0027] B. Configure a NaOH solution with a concentration of 4%, adjust the pH value of the above solution to 9, and slowly add the NaOH solution to the above nickel-manganese sulfate solution under the protection of nitrogen, keep the temperature in a water bath at 80°C, and precipitate the reaction 6h, manganese and nickel precipitates were obtained, filtered, washed, and dried to obtain a certain proportion of nickel-manganese precursors;

[0028] C. Lithium carbonate powder and the above precursor are mixed according to the molar ratio of lithium ...

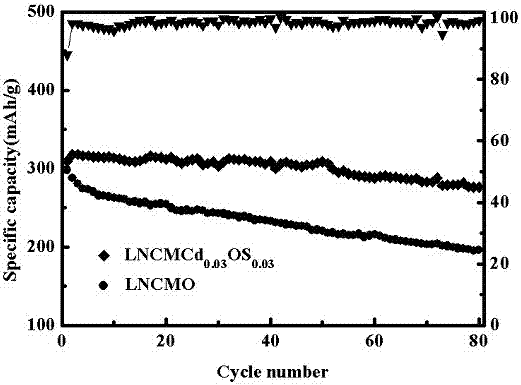

Embodiment 2

[0033] A. Weigh quantitative nickel sulfate (NiSO 4 ), cobalt sulfate (CoSO 4 ), manganese sulfate (MnSO 4 ) was dissolved in deionized water to obtain a nickel-cobalt-manganese sulfate solution, wherein the Ni:Co:Mn molar ratio in the nickel-cobalt-manganese sulfate solution was 0.54:0.13:0.13;

[0034] B. Configure a NaOH solution with a concentration of 4%, adjust the pH value of the above solution to 9, and slowly add the NaOH solution to the above nickel-cobalt-manganese sulfate solution under the protection of nitrogen, keep the temperature in a water bath at 80°C, and precipitate React for 6 hours to obtain manganese, nickel and cobalt precipitates, filter, wash and dry to obtain a certain proportion of nickel-cobalt-manganese precursors;

[0035] C. Lithium carbonate powder and the above precursor are mixed according to the molar ratio of lithium metal to the total metal in the precursor is 1.2:1, then 1% cadmium sulfide powder is added and mixed, ground for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com