Biological fermentation production technology of hyaluronic acid

A bio-fermentation and production process technology, applied in the field of hyaluronic acid bio-fermentation production process, can solve the problems that restrict the production of hyaluronic acid, and achieve the effects of promoting accumulation, increasing production and promoting expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

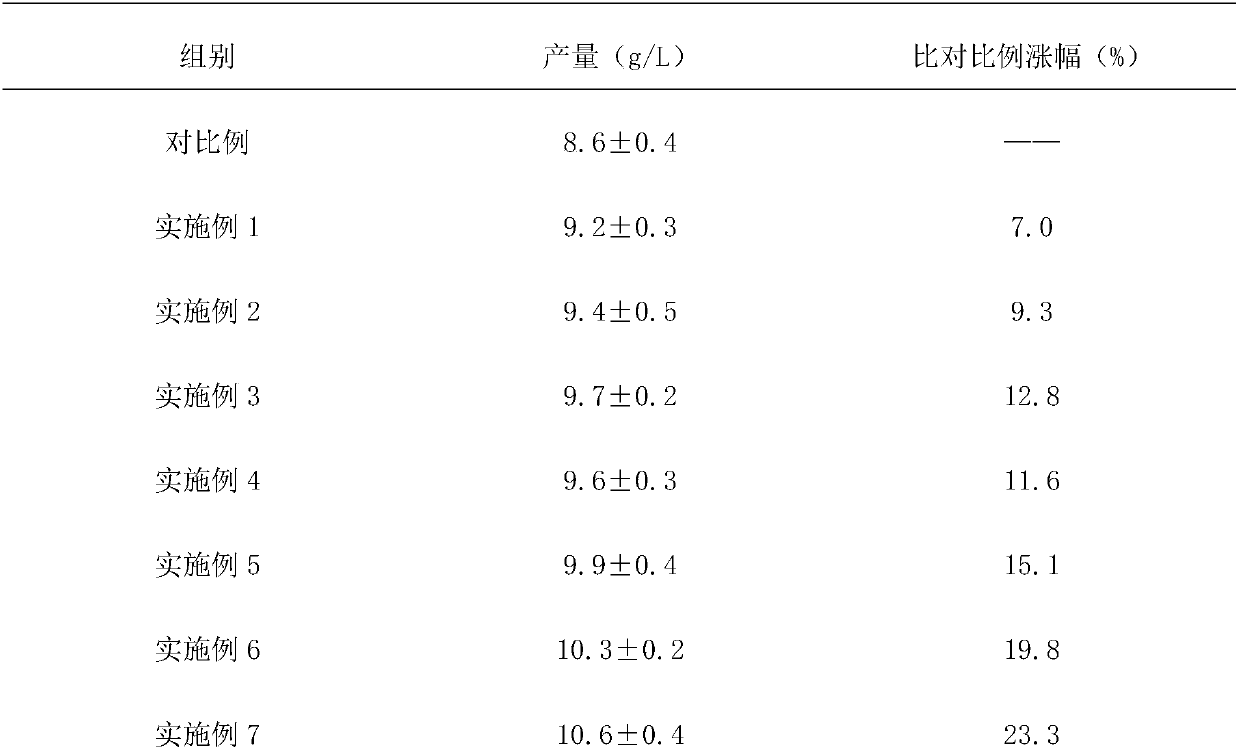

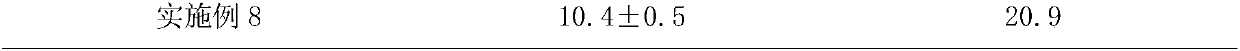

Examples

Embodiment 1

[0034] The present embodiment provides a biofermentation production process of hyaluronic acid, which includes the following steps:

[0035] Step 1: The strain is activated, and the strain is inoculated on the slant medium. The formula of slant medium is: glucose 20g / L, sucrose 2g / L, yeast powder 5g / L, beef extract 3g / L, peptone 3g / L, K 2 HPO 4 1.6g / L, MgSO 4 ·7H 2 O 0.4g / L, agar 2% (mass volume fraction). In an incubator, culture at 37°C for 12 hours to obtain activated strains.

[0036] Step 2: Preparation of seed liquid, inoculate the activated bacteria into a 1L Erlenmeyer flask with sterilized seed medium, and cultivate it for 16 hours at 37°C and 170r / min to obtain seed liquid, and observe the seed liquid under microscope The growth status of the bacteria. The formula of seed medium is: glucose 25g / L, sucrose 5g / L, yeast powder 8g / L, beef extract 4g / L, peptone 4g / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O 0.4g / L.

[0037] Step 3: Expand the culture. If the bacteria i...

Embodiment 2

[0040] This example provides a bio-fermentation production process of hyaluronic acid, which is the same as steps 1 to 3 of the bio-fermentation production process of hyaluronic acid provided in Example 1, the difference is that step 4 in this example is performed as follows :

[0041] Step 4: Fermentation culture. If the growth of the bacteria in the expanded culture medium is good and there is no contamination by bacteria, inoculate the expanded culture medium according to the ratio of expanded culture medium:fermentation medium = 1:6 (v:v) until the 240L 600L fermentation tank for fermentation medium, the formula of fermentation medium is: glucose 37g / L, sucrose 8g / L, yeast powder 11g / L, urea 6g / L, peptone 6g / L, K 2 HPO 4 2.4g / L, MgSO 4 ·7H 2 O 0.5g / L. Keep the ventilation at 4L / min, 200r / min, pH 7.3, and culture at 37°C for 4h. Then keep the ventilation rate at 8L / min, 300r / min, pH 7.3, and the temperature at 32°C, culture for 16h, and add fresh fermentation culture ...

Embodiment 3

[0043] This example provides a bio-fermentation production process of hyaluronic acid, which is the same as steps 1 to 3 of the bio-fermentation production process of hyaluronic acid provided in Example 1, the difference is that step 4 in this example is performed as follows :

[0044] Step 4: Fermentation culture. If the growth of the bacteria in the expanded culture medium is good and there is no contamination by bacteria, inoculate the expanded culture medium according to the ratio of expanded culture medium: fermentation medium = 1:7 (v:v) until the 245L 600L fermentation tank for fermentation medium, the formula of fermentation medium is: glucose 37g / L, sucrose 8g / L, yeast powder 12g / L, urea 8g / L, peptone 8 / L, K 2 HPO 4 2.2g / L, MgSO 4 ·7H 2 O 0.8g / L. Keep the ventilation at 4L / min, 220r / min, pH 7.3, and culture at 37°C for 4h. Then keep the ventilation rate at 4L / min, 250r / min, pH 7.3, and the temperature at 32°C, cultivate for 20h, and add fresh fermentation culture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com