Laboratory detection device and evaluation method for catalytic coefficient of material surface based on LIF detection

A technology of catalytic coefficient and evaluation method, applied in the direction of material excitation analysis, fluorescence/phosphorescence, etc., can solve problems such as the inability to realize independent and precise control of environmental parameters, and a large number of principled experimental researches on the catalytic coefficient of unsuitable materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

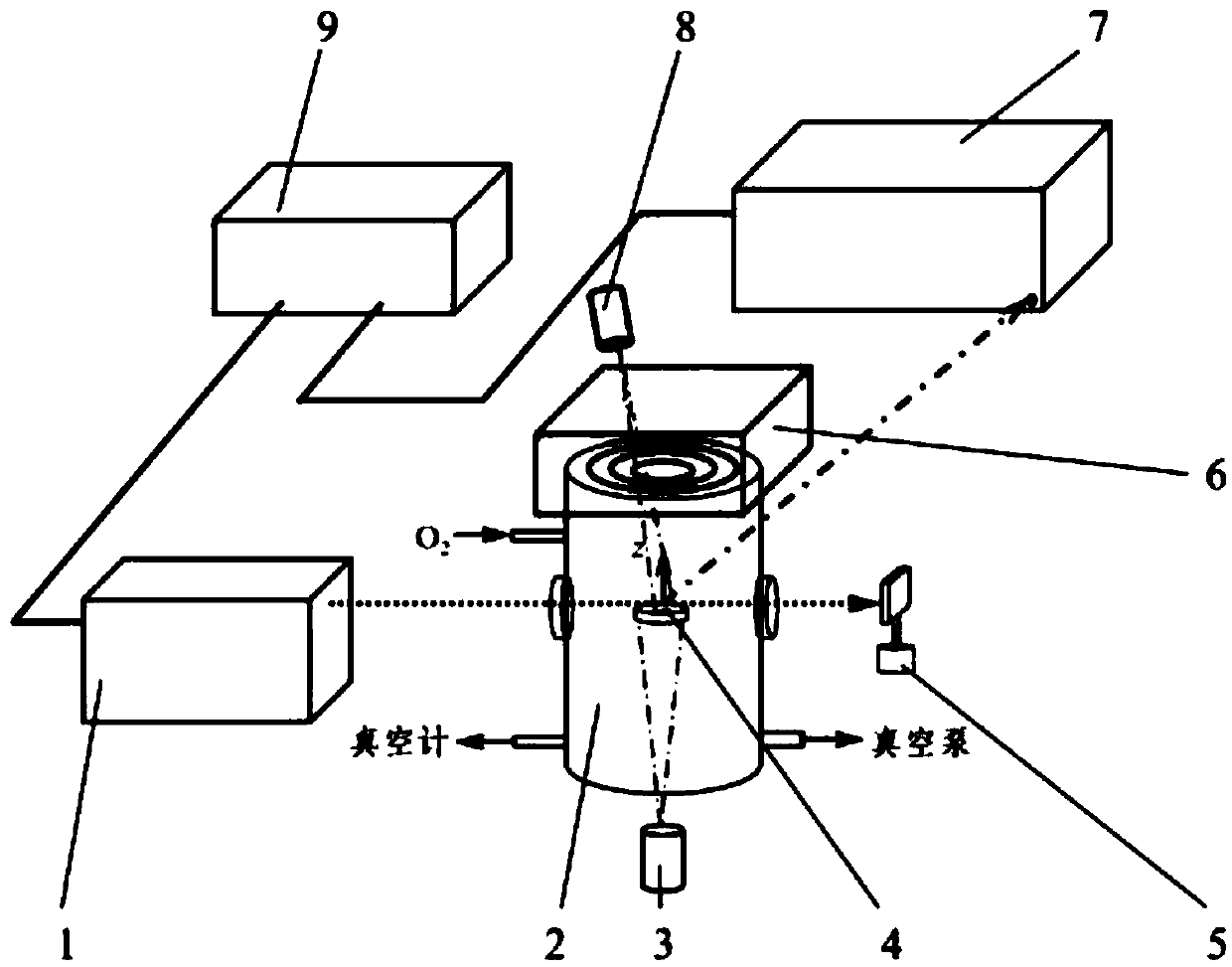

[0046] Specific implementation mode 1: This implementation mode provides a laboratory detection device based on laser-induced fluorescence detection of oxygen atoms, such as figure 1 As shown, the detection device includes a laser induction source and a laser incident adjustment optical path 1, a hollow water-cooled stainless steel cavity 2, a high-power fiber-coupled laser 3, an energy meter 5, a radio frequency power supply 6, a fluorescence imaging optical path and an acquisition device 7, a dual ratio Color pyrometer 8 and synchronous triggering device 9, wherein:

[0047] The laser induction source and the laser incident adjustment optical path 1 can emit a laser with a wavelength of 225.6nm and realize the spatial high-precision movement of the incident laser beam;

[0048] The hollow water-cooled stainless steel cavity 2 is an environmental cavity where the catalytic reaction occurs, and the cavity is connected with devices such as a vacuum pump, a flow meter, and a va...

specific Embodiment approach 2

[0056] Embodiment 2: Two-photon laser-induced fluorescence (TALIF) is used to measure the catalytic coefficient of oxygen atoms on the surface of materials, which is based on TALIF to characterize the temperature and relative concentration of oxygen atoms. For the measurement of oxygen atom temperature and concentration, the excitation laser is scanned in a narrow wavelength range (about 20pm). The translational temperature of the oxygen atom is:

[0057]

[0058] Among them, T O is the translational temperature of the oxygen atom, M O is the relative atomic mass of oxygen atom, c is the speed of light in vacuum, k B is the Boltzmann constant, n A is Avogadro's constant, λ 0 is the central wavelength of the Gaussian curve obtained by wavelength scanning, Δλ T,ICP is the full width at half maximum of the Gaussian curve, Δλ L Instrument broadening for lasers. After measurement, the instrument broadening of the laser involved in the present invention is Δλ L = 2.26pm. ...

Embodiment 1

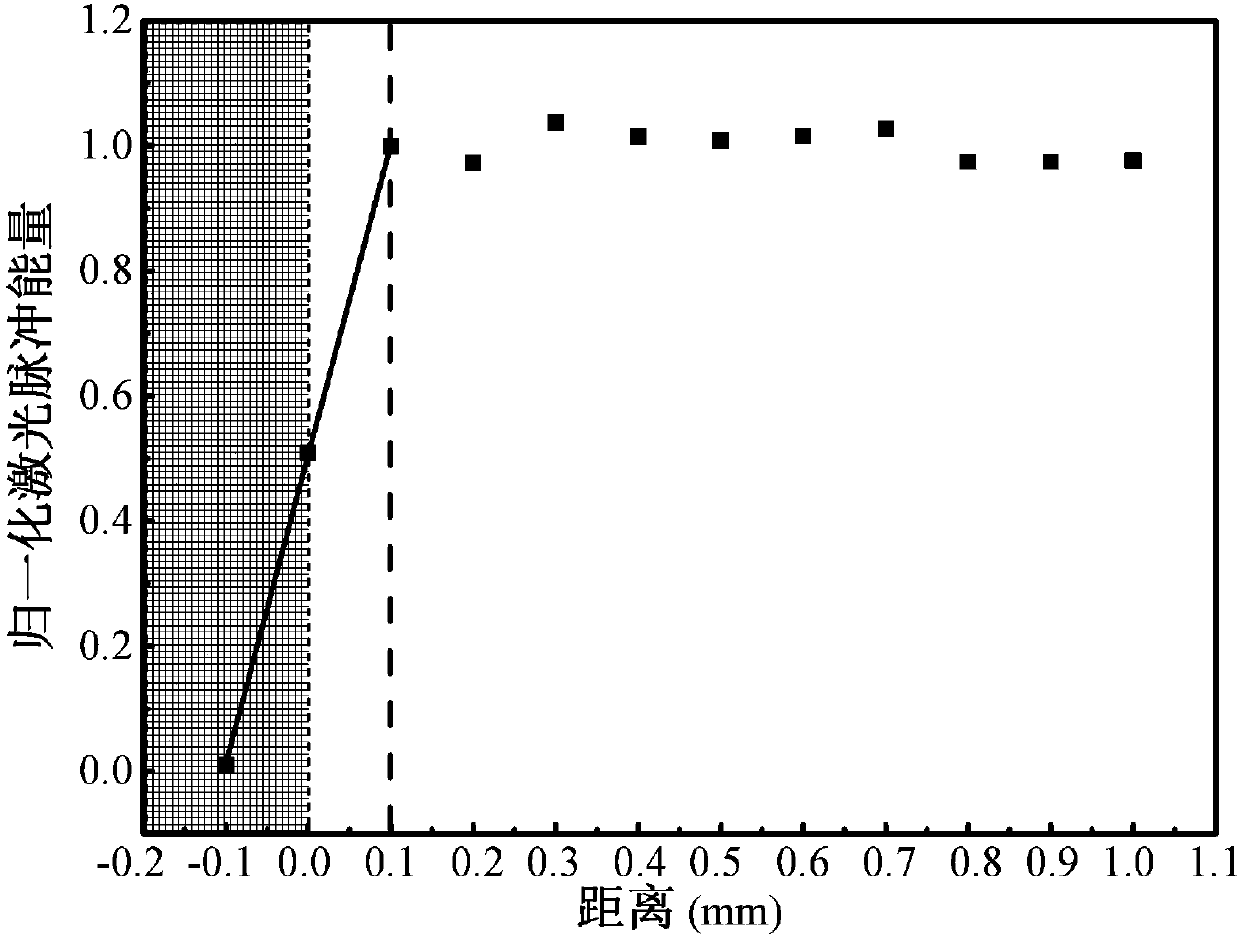

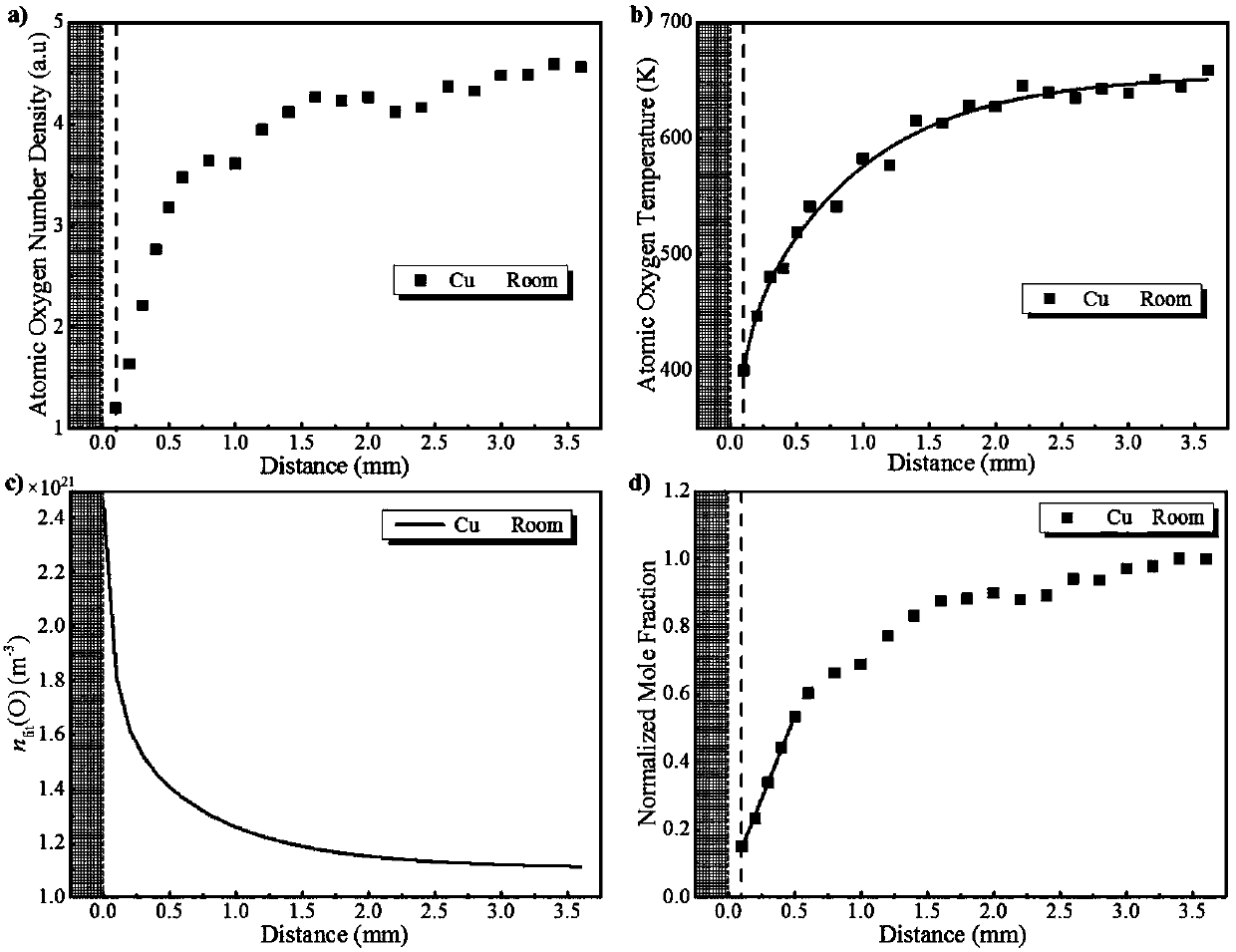

[0095] The plasma discharge power is 1000W, the ambient pressure of the chamber is 10Pa, the oxygen flow rate is 20sccm, the test material is copper (Cu), the sample size is φ12mm×2mm, and the sample is water-cooled to prevent the plasma environment from heating the surface of the material. oxidation. First determine the surface position, and then start from the position with a relative distance of 3.6 mm, and move the laser beam to the sample surface with a displacement of 0.1 mm. The incident wavelength is scanned at each space point to obtain the intensity distribution curve of the oxygen atom fluorescence signal as a function of the wavelength, and then the relative oxygen atom concentration and oxygen atom temperature are obtained. Each space point was tested 5 times and the average value was taken. Finally, according to the atomic mole fraction gradient theory, the surface catalytic reaction rate and catalytic coefficient of Cu material at room temperature are determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com