A silver-based multilayer composite electrical contact material and its preparation method

An electrical contact material, multi-layer composite technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of reduction, high cost, unfavorable silver consumption and production cost, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

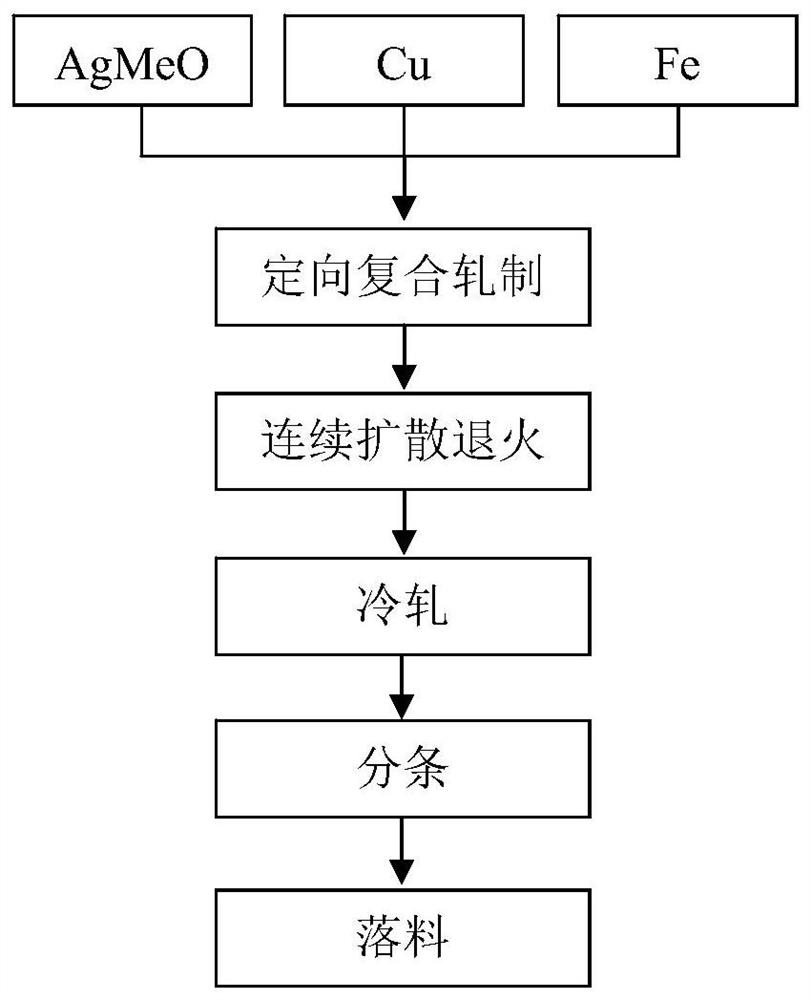

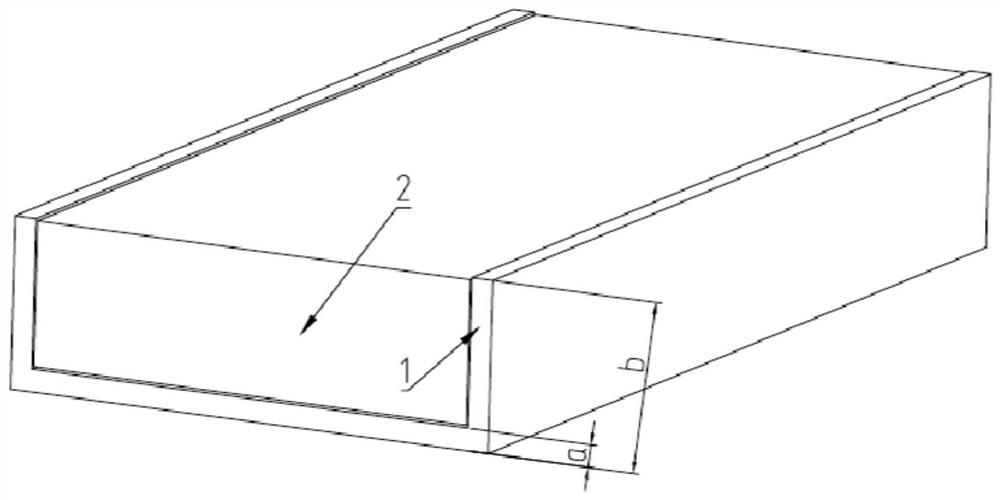

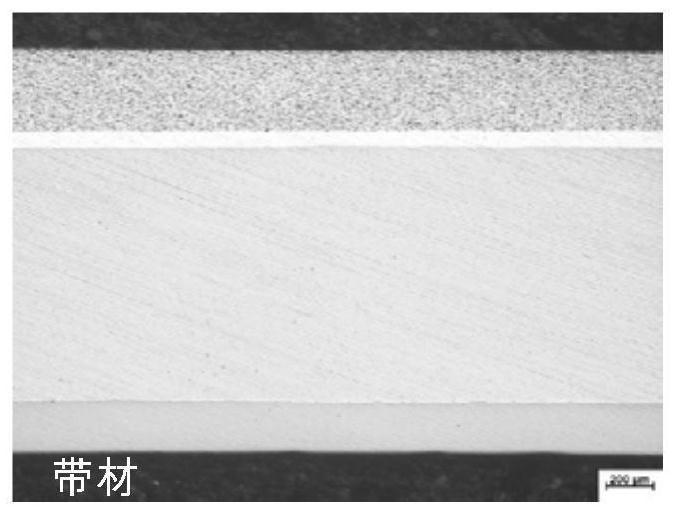

[0037] In this example, AgSnO 2 / Cu / Fe multilayer composite electrical contact material as an example, the specific preparation process is:

[0038] (1) AgSnO was obtained by powder metallurgy technology 2 material, and the AgSnO 2 The material is rolled to a certain thickness to obtain a certain specification of AgSnO 2 plate;

[0039] (2) Place the AgSnO2 plate at the place of pure silver or silver alloy brazing filler metal, and then cold-composite the AgSnO2 and pure silver brazing filler metal layer; hot-roll after holding at 850°C for 3 hours in the air, the thickness of the pure silver brazing filler metal layer accounts for the working 15% of the total thickness of the layer; followed by diffusion annealing heat treatment, the annealing temperature is 650 ℃ and the annealing time is 5h, to obtain the working layer AgSnO 2 Material.

[0040] (3) Put the intermediate layer Cu on the working layer AgSnO 2 Between the welding layer and Fe, the material is rolled into...

Embodiment 2

[0045] In this embodiment, the AgCdO / Cu / Fe multilayer composite electrical contact material is taken as an example, and the specific preparation process is as follows:

[0046] (1) The AgCdO material was obtained by internal oxidation technology, and the AgCdO material was rolled into a certain thickness to obtain a certain specification of the AgCdO plate;

[0047](2) Place the AgCdO plate at the place of pure silver or silver alloy brazing filler metal, cold-composite the AgCdO and pure silver brazing filler metal layer; hot-roll after holding at 860°C for 2.5 hours in the air, the thickness of the pure silver brazing filler metal layer accounts for 18% of the total thickness of the working layer; followed by diffusion annealing heat treatment, the annealing temperature is 700°C and the annealing time is 4h, to obtain the working layer AgCdO material.

[0048] (3) The intermediate layer Cu is placed between the working layer AgCdO and the welding layer Fe, and the material i...

Embodiment 3

[0053] This embodiment takes AgCuO / Cu / Fe multilayer composite electrical contact material as an example, and the specific preparation process is as follows:

[0054] (1) The AgCuO material was obtained through smelting atomization and internal oxidation technology, and the AgCuO material was rolled into a certain thickness to obtain a certain specification of the AgCuO plate;

[0055] (2) Put the AgCuO plate on the place of pure silver or silver alloy brazing filler metal, and cold-composite the AgCuO and pure silver brazing filler metal layer; hot-roll after holding the temperature at 800°C for 3 hours in the air, and the thickness of the pure silver brazing filler metal layer accounts for the working 20% of the total thickness of the layer; followed by diffusion annealing heat treatment, the annealing temperature is 720°C and the annealing time is 3h, to obtain the working layer AgCuO material.

[0056] (3) The intermediate layer Cu is placed between the working layer AgCuO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com