Instant capsule sausage and manufacturing method thereof

A production method and capsule technology, which is applied in the field of instant capsule sausage and its production, can solve the problems that it is difficult to achieve the elasticity and brittleness of instant sausage, the flavor of fruits and vegetables is not outstanding, and it is difficult to achieve coordination and unity, so as to achieve good promotion and market value , Keep the fragrance and taste, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

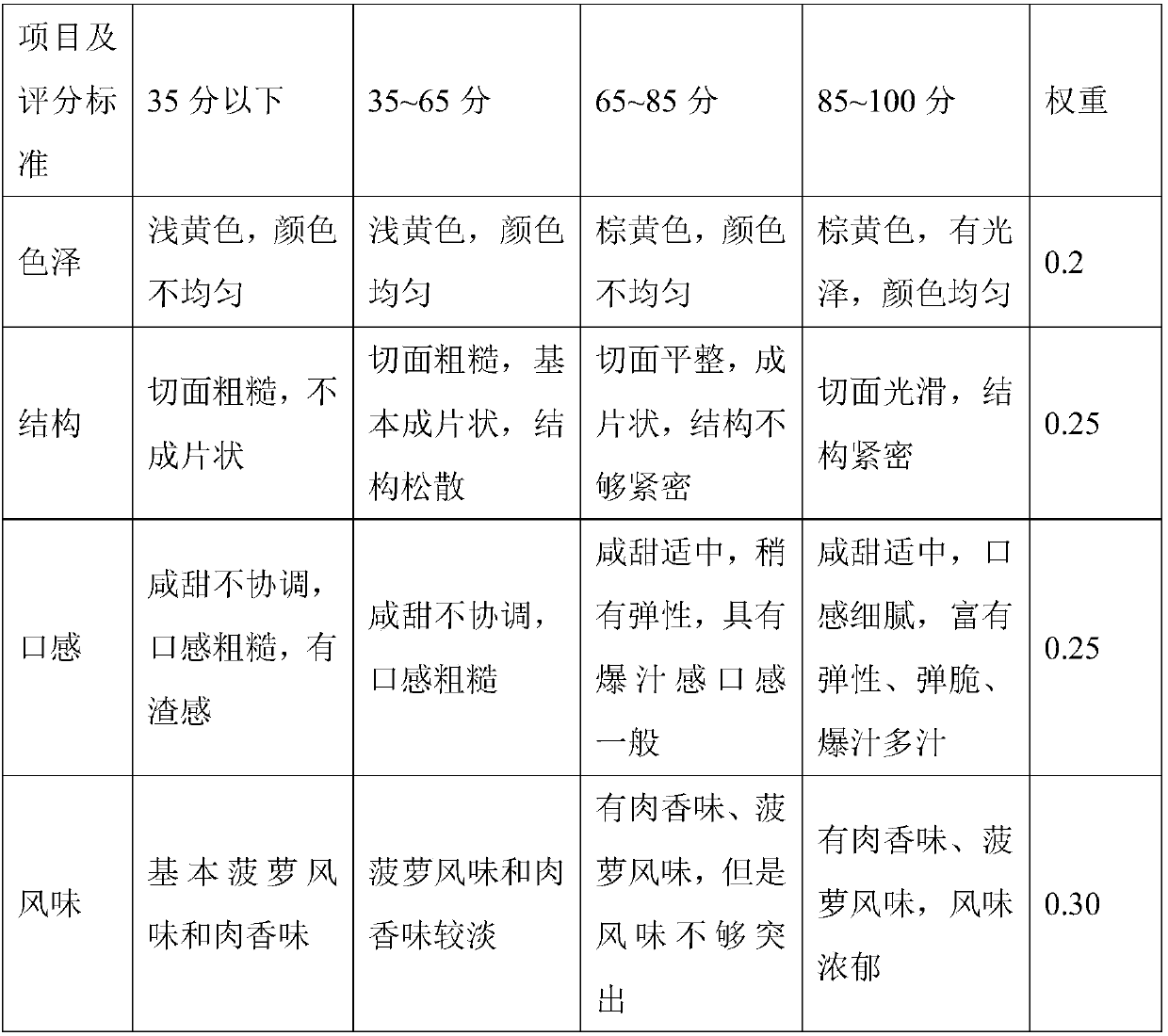

Examples

Embodiment 1

[0044] (1) Instant Capsule Sausage

[0045] The raw material of this embodiment adopts pork hind leg meat, skinless chicken breast meat, pineapple juice capsule as the main ingredients, and is made with auxiliary materials; it is made by the following proportions by weight: 35 parts of pig hind leg meat, skinless chicken breast meat 65 parts, 10 parts of pineapple juice capsules, 40 parts of auxiliary materials; 100 parts of said pineapple juice, 200 parts of capsule materials; 50 parts of gelatin, 50 parts of alginate, 30 parts of glycerin, and 100 parts of water of pineapple juice capsules.

[0046] With the following auxiliary materials in parts by weight: 1.8 parts of edible salt, 0.003 parts of sodium nitrite, 0.1 part of sodium D-isoascorbate, 5.5 parts of white sugar, 10 parts of pea powder, 10 parts of fructose syrup, 1 part of white wine, 11 parts of ice water 0.4 parts of monosodium glutamate, 0.1 parts of pepper, 0.082 parts of food flavor and 0.015 parts of Monascu...

Embodiment 2

[0061] (1) Instant Capsule Sausage

[0062] The raw materials of this embodiment are made of pig hind leg meat, skinless chicken breast meat, and pineapple juice capsules as the main ingredients, together with auxiliary materials; it is made by the following proportions by weight: 30 parts of pig hind leg meat, skinless chicken breast meat 70 parts, 10 parts of pineapple juice capsules, and 25.668 parts of auxiliary materials; wherein, the pineapple juice capsules include pineapple juice and capsule materials, and the capsule materials include gelatin, alginate, glycerin and water, the parts by weight of pineapple juice and capsule materials The ratio is 1:2, and the ratio of parts by weight of gelatin, alginate, glycerin and water is 5:5:3:10.

[0063] Be equipped with the following auxiliary materials in parts by weight: auxiliary materials include 1.5 parts of edible salt, 0.003 parts of sodium nitrite, 0.1 part of D-sodium erythorbate, 3 parts of white sugar, 8 parts of pe...

Embodiment 3

[0067] (1) Instant Capsule Sausage

[0068] The raw materials of this embodiment are made of pig hind leg meat, skinless chicken breast meat, and pineapple juice capsules as main ingredients, together with auxiliary materials; it is made by the following proportions by weight: 60 parts of pig hind leg meat, skinless chicken breast meat 40 parts, 8 parts of pineapple juice capsules, 40.2 parts of auxiliary materials; 100 parts of the pineapple juice, 200 parts of capsule material; 50 parts of gelatin, 50 parts of alginate, 30 parts of glycerin, and 100 parts of water of the pineapple juice capsule.

[0069] Be equipped with the following auxiliary materials in parts by weight: 2 parts of edible salt, 0.003 parts of sodium nitrite, 0.1 part of sodium D-isoascorbate, 5.5 parts of white sugar, 10 parts of pea powder, 10 parts of fructose syrup, 1 part of white wine, and 11 parts of ice water 0.4 parts of monosodium glutamate, 0.1 parts of pepper, 0.082 parts of food flavor and 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com