CMR grade PVC (Polyvinyl Chloride) cable material as well as preparation method and application thereof

A technology of cable material and PVC resin, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor plasticization efficiency of flame-retardant plasticizers, hard data lines, and difficult data lines, etc., to achieve Effects of reducing hardness, improving softness, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

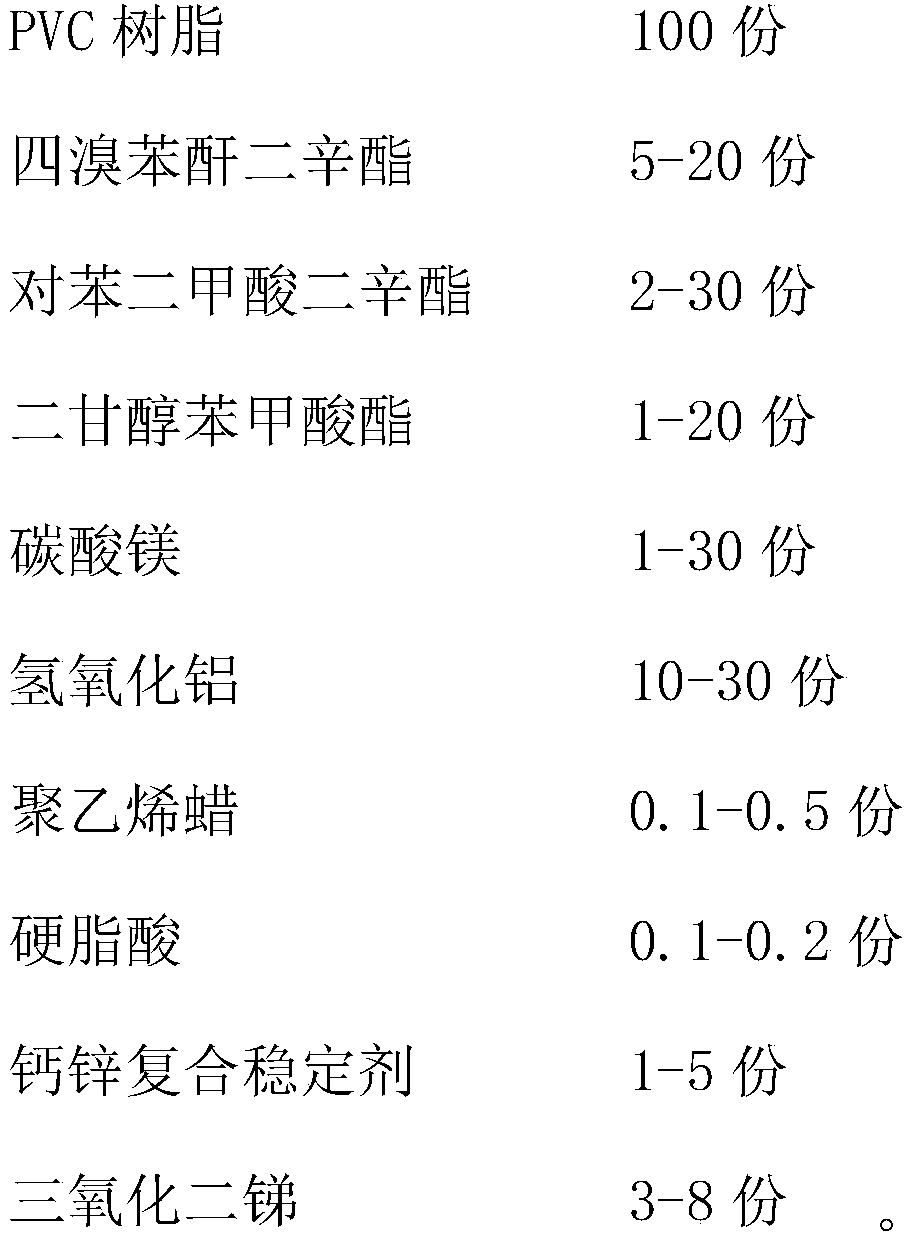

[0020] A kind of CMR level PVC cable material of the present embodiment comprises the following components by weight:

[0021]

[0022]

[0023] Among them, the PVC resin is an environmentally friendly SG-3 type PVC resin with a polymerization degree of 1300.

[0024] The mesh number of aluminum hydroxide is 3000 mesh.

[0025] The purity of antimony trioxide is 99.8%.

[0026] A kind of preparation method of above-mentioned CMR grade PVC cable material, comprises the steps:

[0027] S1: PVC resin, dioctyl tetrabromophthalic anhydride, dioctyl terephthalate, diethylene glycol benzoate, magnesium carbonate, aluminum hydroxide, polyethylene wax, stearic acid, calcium zinc composite stabilizer, Antimony trioxide is added to the high mixer for mixing and plasticizing;

[0028] S2: Put the uniformly stirred raw materials directly into the twin-screw extruder for extrusion processing; then extrude and granulate through the single-screw extrusion granulator;

[0029] S3: Th...

Embodiment 2

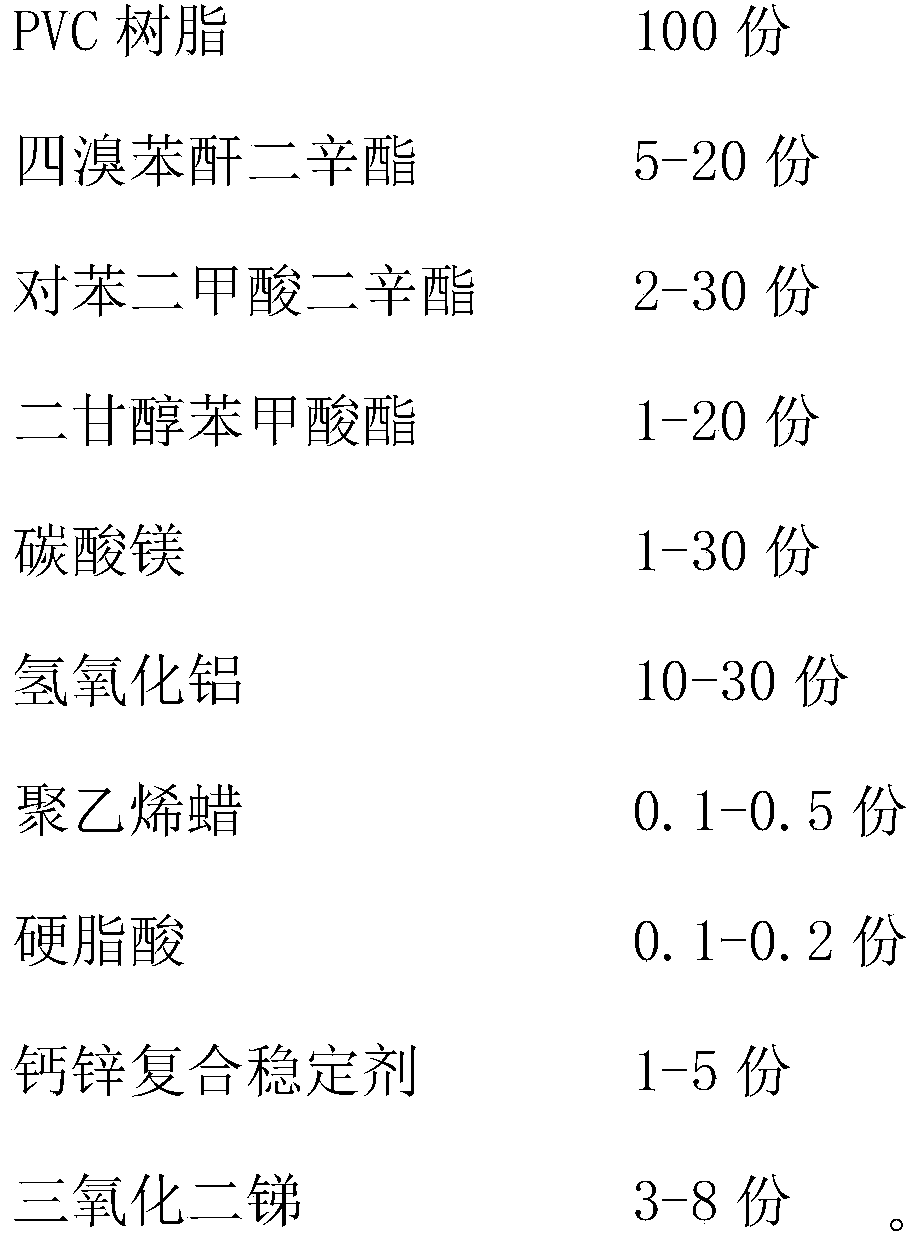

[0031] A kind of CMR level PVC cable material of the present embodiment of the present embodiment comprises the following components by weight:

[0032]

[0033]

[0034] Among them, the degree of polymerization of PVC resin is 1400.

[0035] The mesh number of aluminum hydroxide is 4000 mesh.

[0036] The purity of antimony trioxide is 99.9%.

[0037] A kind of preparation method of above-mentioned CMR grade PVC cable material, comprises the steps:

[0038] S1: PVC resin, dioctyl tetrabromophthalic anhydride, dioctyl terephthalate, diethylene glycol benzoate, magnesium carbonate, aluminum hydroxide, polyethylene wax, stearic acid, calcium zinc composite stabilizer, Antimony trioxide is added to the high mixer for mixing and plasticizing;

[0039] S2: Put the uniformly stirred raw materials directly into the twin-screw extruder for extrusion processing; then extrude and granulate through the single-screw extrusion granulator;

[0040] S3: The extruded finished produc...

Embodiment 3

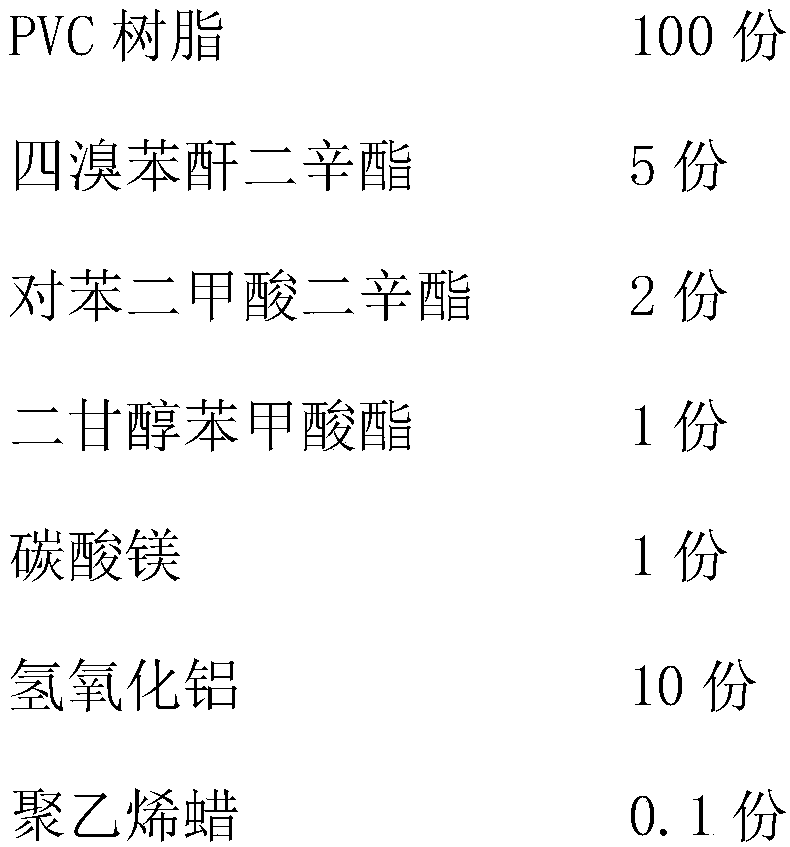

[0042] A kind of CMR level PVC cable material of the present embodiment of the present embodiment comprises the following components by weight:

[0043]

[0044]

[0045] Among them, the PVC resin is an environmentally friendly SG-3 type PVC resin with a polymerization degree of 1500.

[0046] The mesh number of aluminum hydroxide is 5000 mesh.

[0047] The purity of antimony trioxide is 99.8%.

[0048] A kind of preparation method of above-mentioned CMR grade PVC cable material, comprises the steps:

[0049] S1: PVC resin, dioctyl tetrabromophthalic anhydride, dioctyl terephthalate, diethylene glycol benzoate, magnesium carbonate, aluminum hydroxide, polyethylene wax, stearic acid, calcium zinc composite stabilizer, Antimony trioxide is added to the high mixer for mixing and plasticizing;

[0050] S2: Put the uniformly stirred raw materials directly into the twin-screw extruder for extrusion processing; then extrude and granulate through the single-screw extrusion gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com