Efficient foaming agent for air foam displacement of reservoir oil and preparation method of efficient foaming agent

A technology of air foam flooding and foaming agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor water carrying capacity, strong corrosion of equipment and pipelines, etc., and achieve low cost and significant corrosion inhibition effect , Good effect of synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

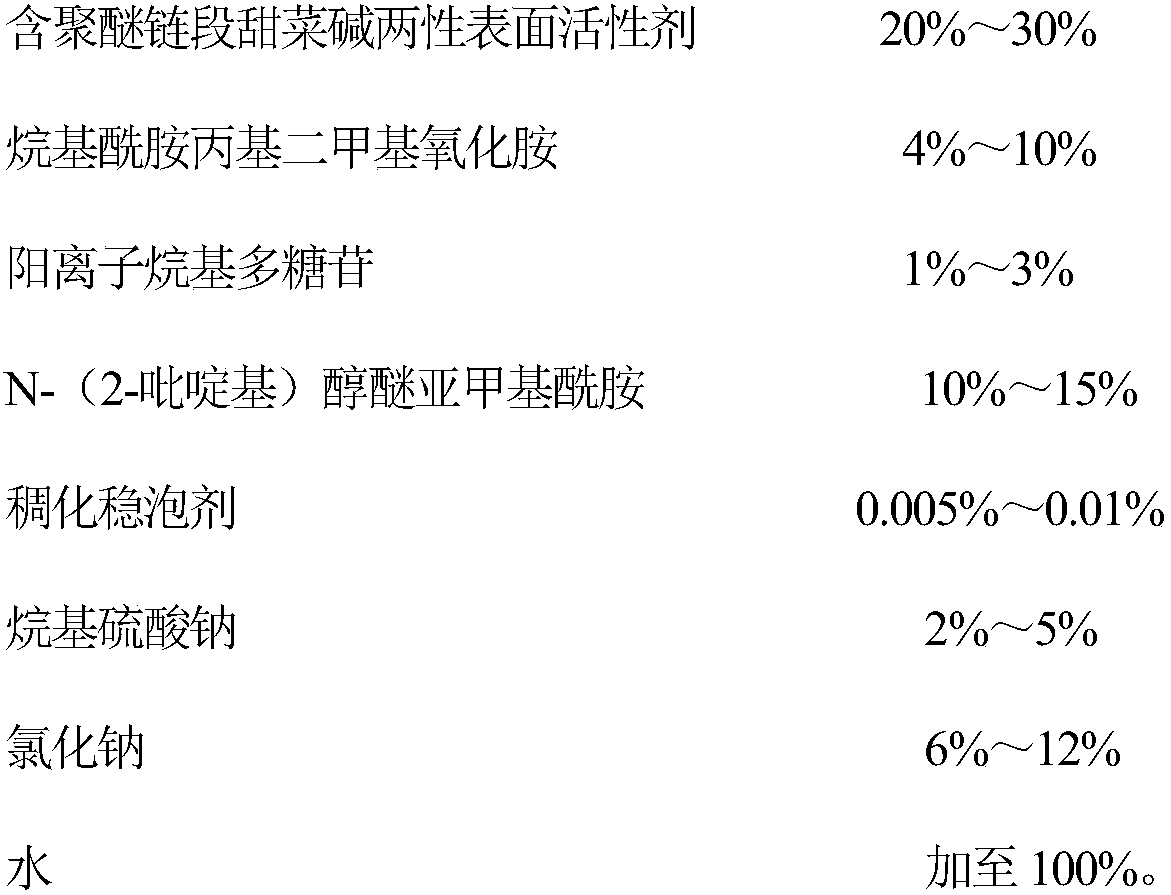

[0027] Taking the preparation of 1 kg of foaming agent for air foam displacement of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0028]

[0029]

[0030] The preparation method is as follows: first add 0.6% of the thickened foam stabilizer into water at about 25°C, stir while adding, completely disperse and dissolve, and put it into a plastic bucket for standby. Then 250g lauryl polyoxyethylene ether betaine, 50g lauryl amidopropyl dimethylamine oxide, 20g cationic dodecyl polyglucoside, 110g N-(2-pyridyl) alcohol ether methylene Base amide, 30g alkyl sodium sulfate, 90g sodium chloride, 440g water, 10g thickened foam stabilizer (0.6% aqueous solution) are added into the stirring tank according to the ratio in the formula in turn, and it can be stirred evenly.

Embodiment 2

[0032] Taking the preparation of 1 kg of foaming agent for air foam displacement of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0033]

[0034] Its preparation method is identical with embodiment 1.

Embodiment 3

[0036] Taking the preparation of 1 kg of foaming agent for air foam displacement of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0037]

[0038]

[0039] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com