A kind of transfer method of ultra-thin anodized aluminum film

An anodized aluminum oxide transfer method technology, which is applied in the transfer field of ultra-thin anodized aluminum oxide film, can solve the problems of detachment from the substrate, low success rate, and long time-consuming AAO, and achieve high-efficiency transfer, high success rate, and time-consuming transfer short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

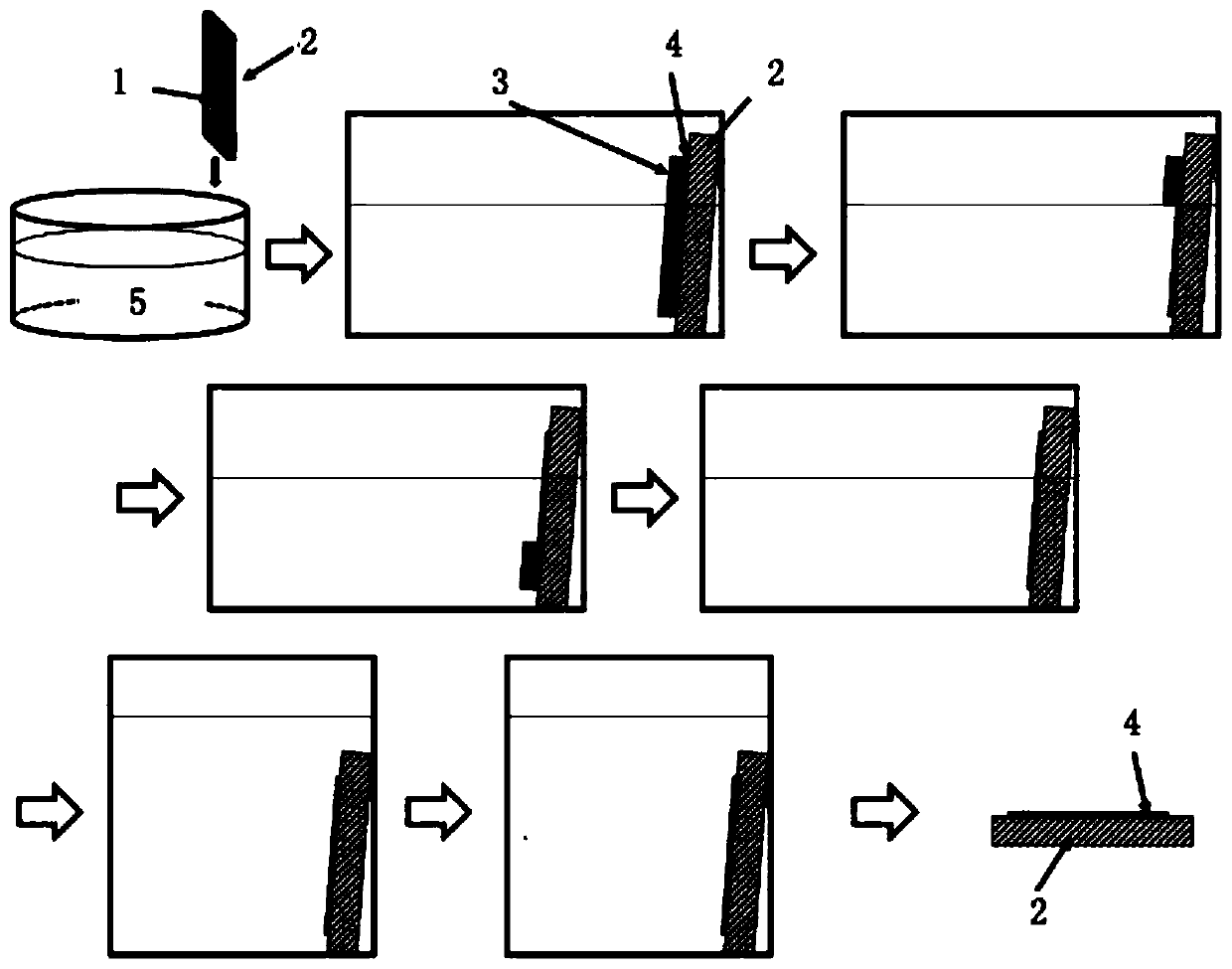

[0025] A method for transferring an ultra-thin anodized aluminum oxide film, comprising the following steps: S1, getting an anodized aluminum oxide ultra-thin film with a polymethyl methacrylate support layer that is a PMMA / AAO composite film is placed on a target substrate, wherein the anode The thickness of aluminum oxide ultra-thin film is 50nm, and target substrate is a silicon chip, and PMMA / AAO composite film is fixed on the target substrate surface with clamp; S2, then a part of the target substrate with composite film is immersed in the support layer removal solution for 2min, The part of the composite film immersed in the support layer removal solution accounts for 50% of the total area of the composite film, and is taken out; S3, after the support layer removal solution is evaporated, another part of the target substrate with the composite film is immersed in the support layer removal solution for 2 minutes, and taken out ; S4. After the support layer removal soluti...

Embodiment 2

[0027] A method for transferring an ultra-thin anodized aluminum oxide film, comprising the following steps: S1, getting an anodized aluminum oxide ultra-thin film with a polymethyl methacrylate support layer that is a PMMA / AAO composite film is placed on a target substrate, wherein the anode The thickness of the aluminum oxide ultra-thin film is 5000nm, and the target substrate is a quartz plate, and the PMMA / AAO composite film is fixed on the target substrate surface with a clamp; S2, subsequently immersing a part of the target substrate with the composite film in the support layer removal solution for 60min, The part of the composite film immersed in the support layer removal solution accounts for 90% of the total area of the composite film, and is taken out; S3, after the support layer removal solution is evaporated, another part of the target substrate with the composite film is immersed in the support layer removal solution for 60 minutes, and taken out ; S4. After the ...

Embodiment 3

[0029]A method for transferring an ultra-thin anodized aluminum oxide film, comprising the following steps: S1, getting an anodized aluminum oxide ultra-thin film with a polymethyl methacrylate support layer that is a PMMA / AAO composite film is placed on a target substrate, wherein the anode The thickness of the aluminum oxide ultra-thin film is 2500nm, and the target substrate is a sapphire sheet. The PMMA / AAO composite film is a large-area ultra-thin anodized aluminum oxide porous film prepared by the method in ZL2015108938946. The PMMA / AAO composite film is fixed on the target substrate with a clamp Surface; S2, then immerse a part of the target substrate with the composite film in the support layer removal solution for 30min, the part of the composite film immersed in the support layer removal solution accounts for 70% of the total area of the composite film, and take it out; S3, the support layer removal solution volatilizes After drying, immerse another part of the targ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com