In-situ visualization method of dispersity of inorganic filler in plastic

A technology of inorganic fillers and inorganic substances, applied in the field of material dispersity evaluation, can solve the problems of limited test range, inability to effectively evaluate dispersity, and complicated sample preparation, and achieve the effects of short marking time, stable and reliable marking process, and rapid response.

Active Publication Date: 2018-01-19

BEIJING UNIV OF CHEM TECH

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the current evaluation of the degree of dispersion mostly relies on electron microscopic imaging, and this method cannot achieve an effective evaluation of the degree of dispersion due to the constraints of complex sample preparation and limited testing range.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

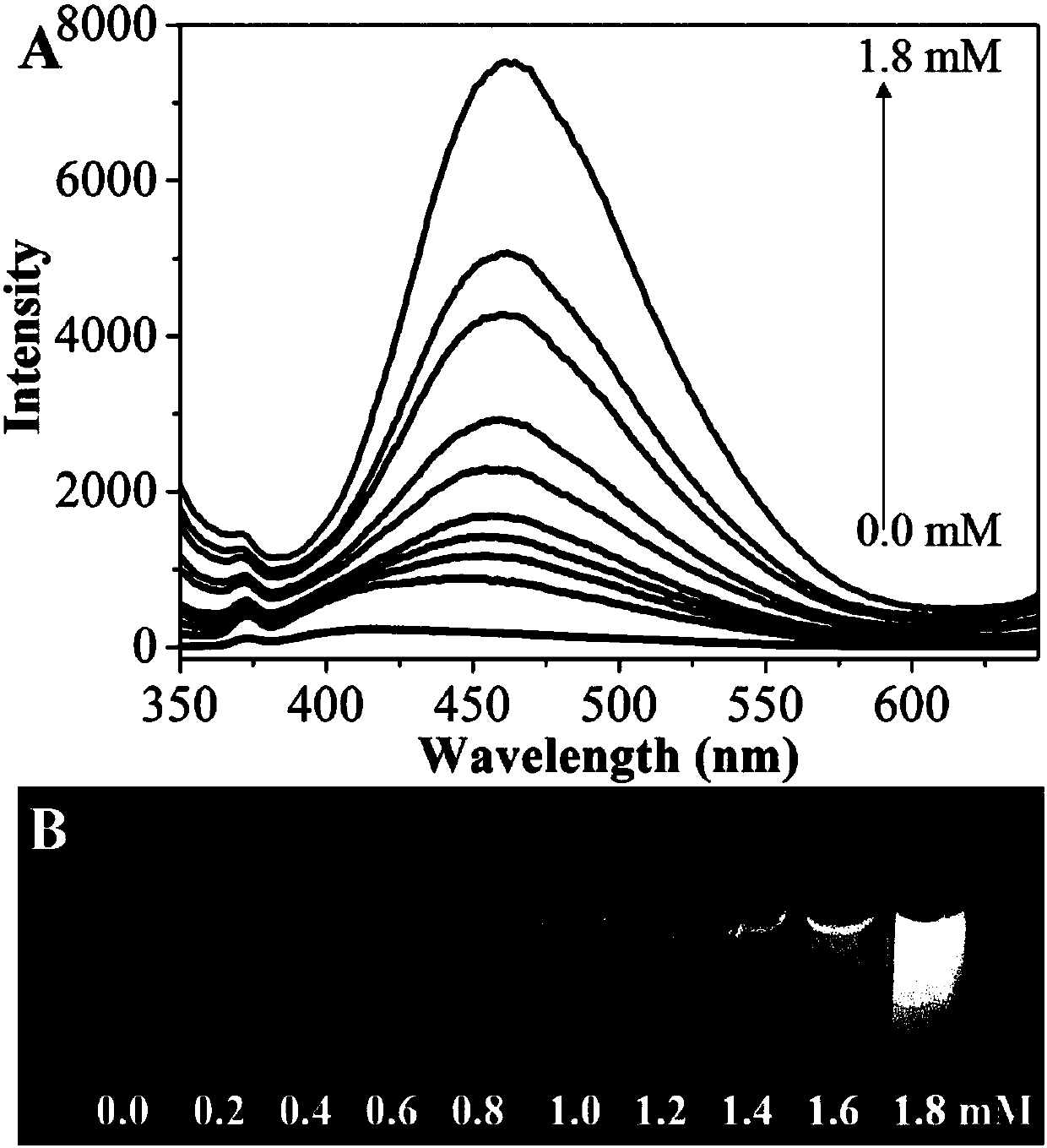

[0030] (1) Configuration of boric acid TPEDB solution

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

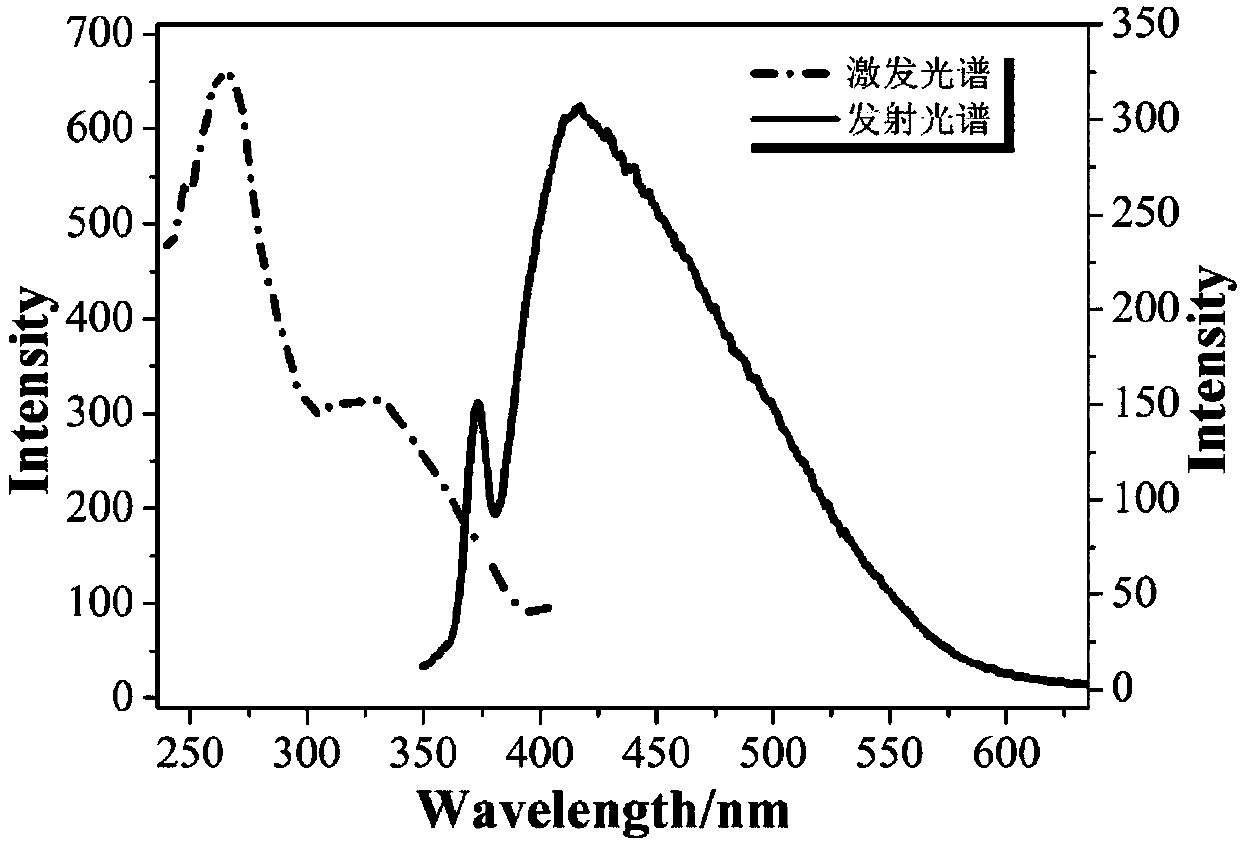

The invention discloses an in-situ visualization method of dispersity of an inorganic filler in plastic, belongs to the technical field of filler dispersity in plastic and relates to a method for special identification dyeing screening of an inorganic filler in plastic after film formation. Based on special identification of boronic acid-modified fluorescent molecules and surface hydroxyl of a layered filler, the inorganic filler in a press-molded plastic film is subjected to fluorescent labeling and through a fluorescence microscope or a confocal laser scanning microscope, the visualization result is measured and analyzed. The method is free of pre-modification or treatment on the inorganic filler, only utilizes immersion of any plastic film in boric acid fluorescent molecules, is an in-situ, non-destructive, rapid and effective visual identification method and can be widely used for effective screening of an inorganic filler in a composite material in the factory.

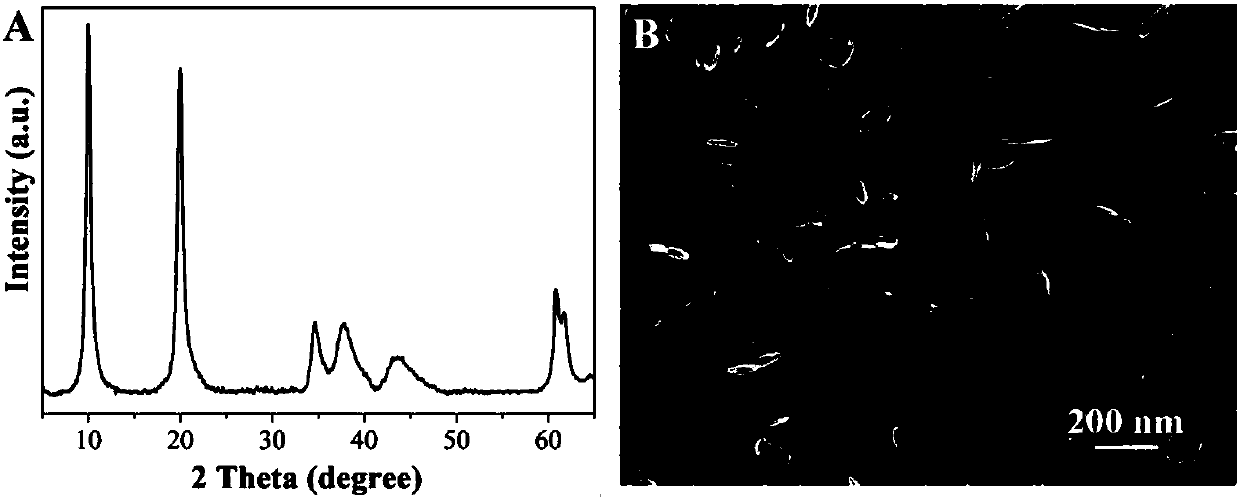

Description

technical field [0001] The invention belongs to the technical field of material dispersion evaluation, and in particular relates to a method for visually screening the dispersion of inorganic fillers in plastics through specific identification and dyeing after film formation. Background technique [0002] Two-dimensional inorganic layered materials (such as hydrotalcite LDHs, montmorillonite MMT, etc.) have been widely used as functional fillers in plastic products (such as polyethylene PE, polypropylene PP, etc.), with good preparation stability and strong functionality. organic-inorganic composite materials. In order to fully realize the functions of these nanofillers, their degree of dispersion in plastics is a very important indicator, which directly affects the mechanical properties, stability and functionality of composite materials. Therefore, the evaluation of the dispersion of inorganic fillers is of great significance in both theoretical research and industrial pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/64

Inventor 吕超田锐段雪

Owner BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com