IC package processing device and processing method

A technology for processing devices and packages, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as high cost, long processing cycle, and cumbersome control, and achieve smooth control between processes, easy stripping, and optimization The effect of encapsulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

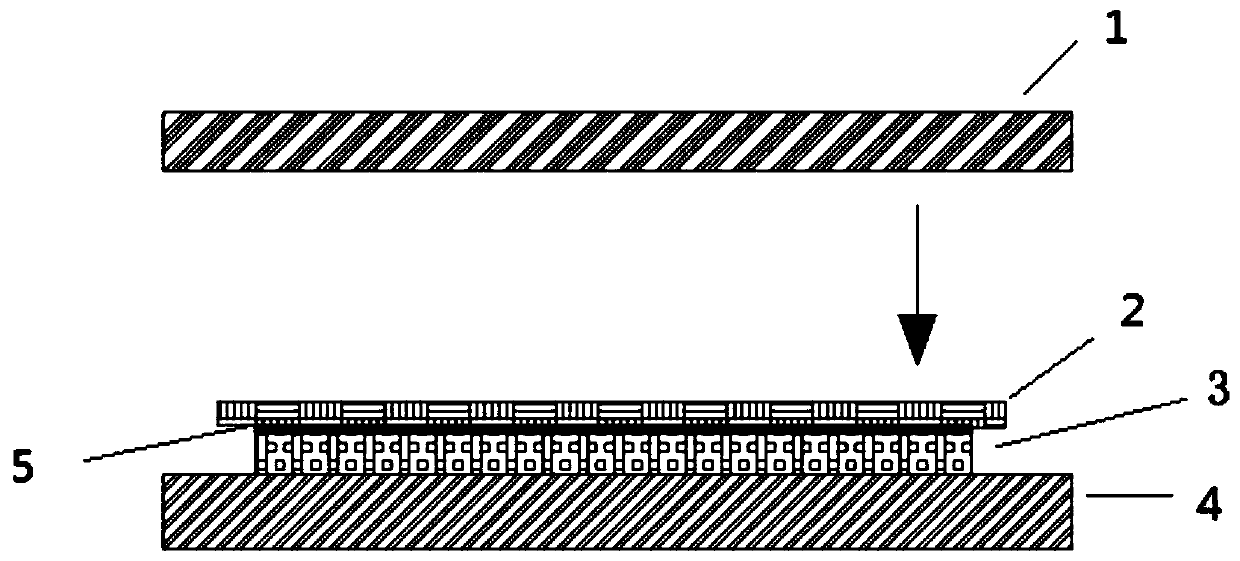

[0036] Such as figure 1 As shown, it shows a schematic diagram of the working state of the IC packaging processing device in this embodiment, and the device includes:

[0037] The first temperature-controlled chuck 1 is used to absorb the metal carrier 2 and heat the carrier.

[0038] The second temperature-controlled suction cup 4 is used to absorb the IC package body 3 and control the IC package body to keep within the first temperature range.

[0039] The separation device is used to activate when the temperature of the metal carrier is heated to a second temperature range by the first temperature-controlled chuck, so as to separate the metal carrier from the IC package. In this embodiment, there is a low melting point metal plating layer 5 between the metal carrier 2 and the IC package 3 .

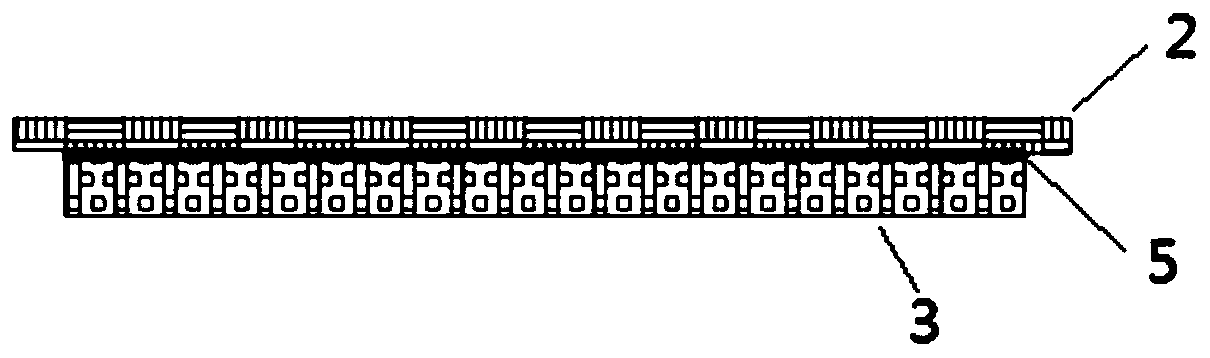

[0040] In this embodiment, the working process of the device includes: the IC packages to be processed are sent into the processing device, such as figure 2 As shown, the IC packag...

Embodiment 2

[0043] Such as figure 1 As shown, it shows a schematic diagram of the working state of the IC packaging processing device in this embodiment, and the device includes:

[0044] The first temperature-controlled chuck 1 is used to absorb the metal carrier 2 and heat the carrier. In a specific device configuration, the suction cup may include a heating unit and an adsorption unit. The heating unit may adopt a non-contact heating method or a contact heating method.

[0045] In some examples, contact and non-contact heating units can also be used simultaneously to meet the needs of different temperature control and heating methods.

[0046] In some examples, the non-contact heating unit includes a high frequency electromagnetic heating subunit.

[0047] In some examples, the contact heating unit includes at least one of an electric heating subunit and a thermal medium heating subunit.

[0048]In some examples, the adsorption unit of the first temperature-controlled chuck include...

Embodiment 3

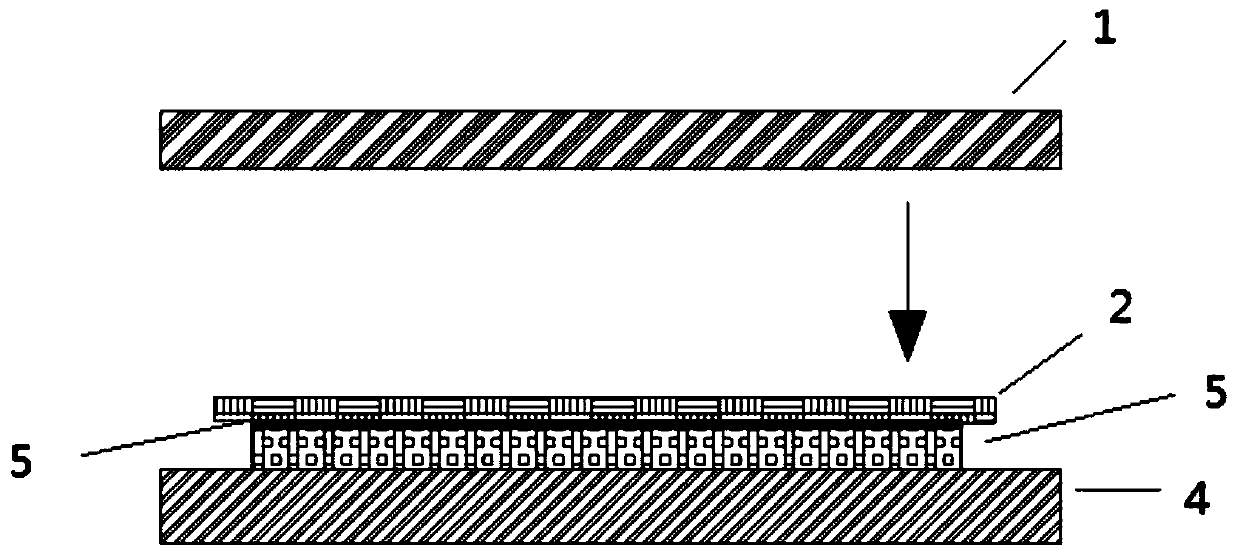

[0055] Such as image 3 , 4 As shown, this embodiment discloses a method for post-processing the IC package, including the following steps:

[0056] Step 1. Inserting step: placing the non-metallic side of the IC package to be processed into the second temperature-controlled suction cup.

[0057] Specifically, the second temperature-controlled suction cup can be a vacuum adsorption suction cup, such as a porous negative pressure adsorption device. The porous negative pressure adsorption device can have a disk-shaped shape, and gas circulation pipes are distributed on its surface, and the pump device can be used to pump air to the outside through the gas circulation pipes, so as to realize negative pressure on the surface of the suction cup and the adsorbed object, so that the two are closely connected. connect.

[0058] There is a cooling medium inside the suction cup, and when the temperature exceeds a predetermined value, the temperature of the IC package absorbed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com