Dual-surface treatment method for photoelectric conversion efficiency of barium-stannate-based dye-sensitized solar cell

A technology for photoelectric conversion efficiency and solar cells, which is applied in the field of dye-sensitized solar cells, can solve the problems that photoelectric conversion efficiency needs to be improved, and achieve the effects of improving photoelectric conversion efficiency, high practicability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The double-surface treatment method for improving the photoelectric conversion efficiency of a barium stannate-based dye-sensitized solar cell comprises the following steps:

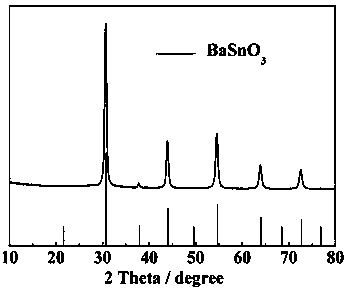

[0023] (1) BaSnO 3 The preparation method of nanoparticles and slurry: First, dissolve tin tetrachloride pentahydrate and barium chloride in 40-200ml of hydrogen peroxide in equal amounts, wherein tin tetrachloride pentahydrate is 2-5 mmol to obtain a clear solution . Add 25-28 wt % concentrated ammonia water dropwise to the clear solution to adjust the pH of the solution between 9-11 to obtain a white turbid solution. It was transferred to a round bottom flask and heated in a water bath at 50-90°C for 5-8h to obtain a white precipitate. The precipitate was washed three times by centrifugation with deionized water and ethanol, so that the pH of the supernatant was close to neutral, and then dried in an oven at 70 °C for 8 h. Finally, use a muffle furnace to heat up to 500-800°C at a rate of 2°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com