Flame-retardant PP (polypropylene) pipe

A flame retardant and flame retardant layer technology, applied in the field of flame retardant PP pipe, can solve the problems of poor thermal insulation, weak rigidity, insufficient flame retardant, etc., to achieve stable flame retardant effect, prolong service life, and improve resistance The effect of burning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

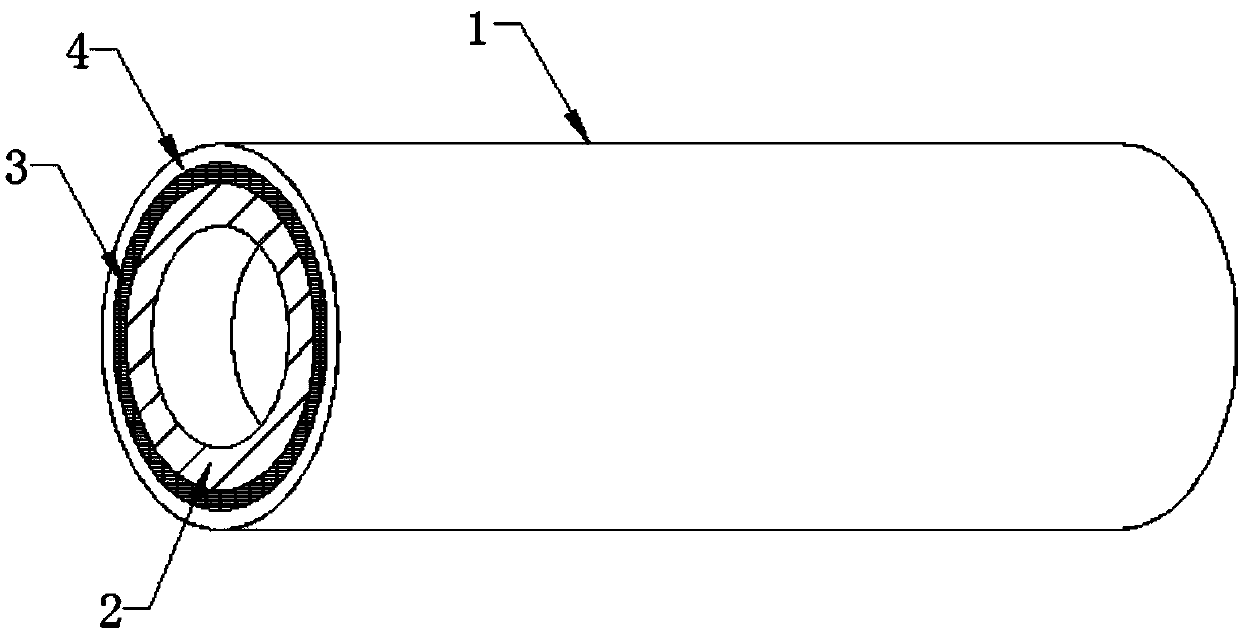

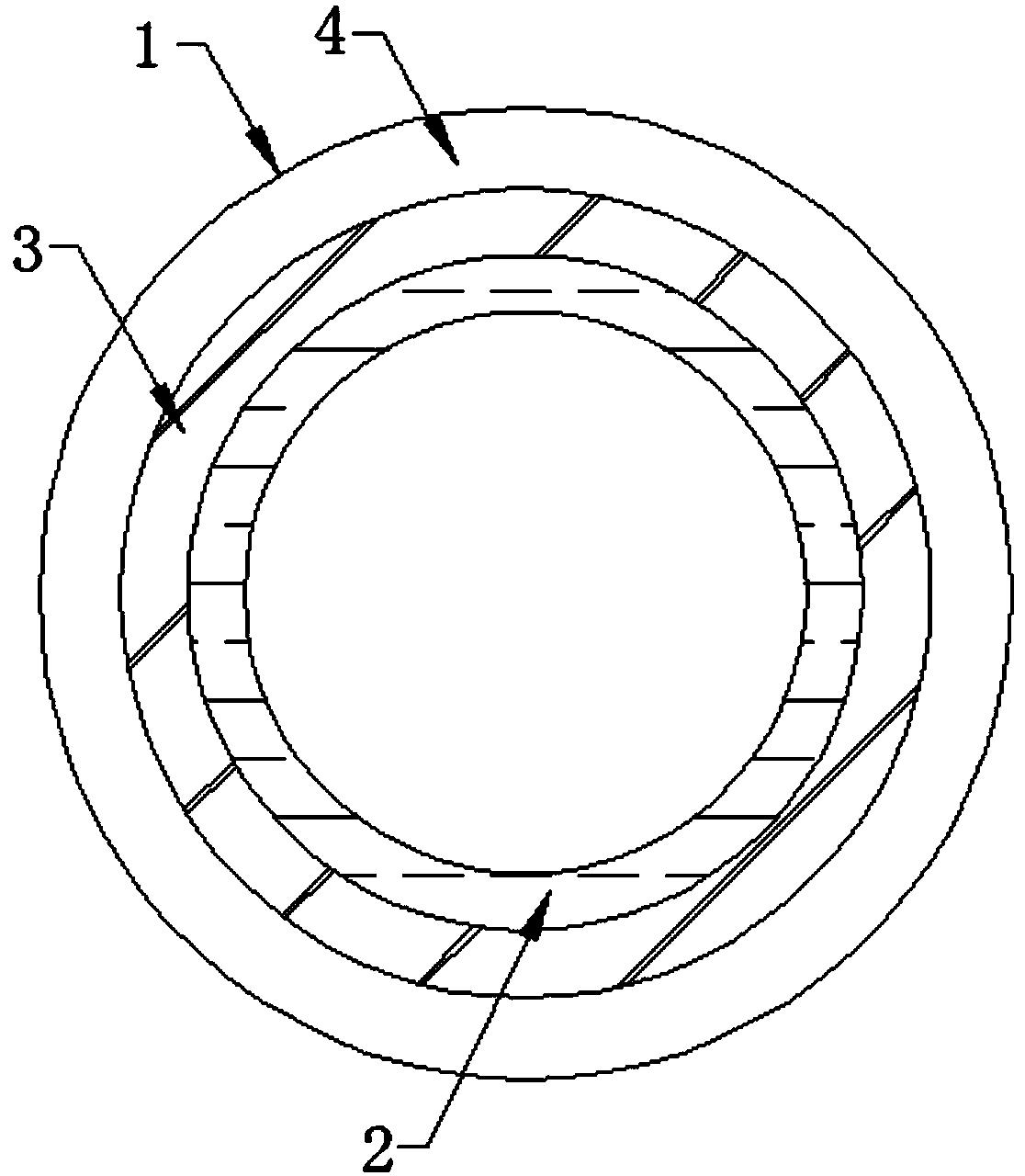

[0022] Such as Figure 1-2 As shown, the present invention provides an anti-flame retardant PP pipe and a manufacturing method thereof, including a main body 1, and the main body 1 is provided with an inner layer 2, a composite reinforcement layer 3 and a flame-retardant layer 4 sequentially from the inside to the outside, and the composition of the inner layer 2 is as follows: The ratio is 2-4 parts of calcium zinc stabilizer, 4-5 parts of ACR, 2-3 parts of PE wax, 10-15 parts of nitrile rubber, 6-8 parts of chlorinated polyethylene, 2-3 parts of graphite, and 2 parts of microcrystalline paraffin -3 parts, 8-10 parts of nano calcium carbonate, 4-5 parts of titanium dioxide, 160-180 parts of PP resin, 3-4 parts of calcium stearate, 3-4 parts of glass fiber, 6-8 parts of oxidized polyethylene wax , the composition ratio of the flame retardant layer 4 is 5-10 parts of vinyl acetate, 0.2-0.3 parts of stearic acid, 20-25 parts of light calcium, 1.5-2 parts of rare earth nitrate, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com