System and method for recycling warm water discharge from costal power plants

A technology for warm drainage and power plants, applied in the environmental field, can solve the problems of wasting energy, shortening the treatment period, environmental pollution, etc., and achieve the effects of accurately controlling the temperature of the air supply, improving the degree of comprehensive utilization, and improving the efficiency of composting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

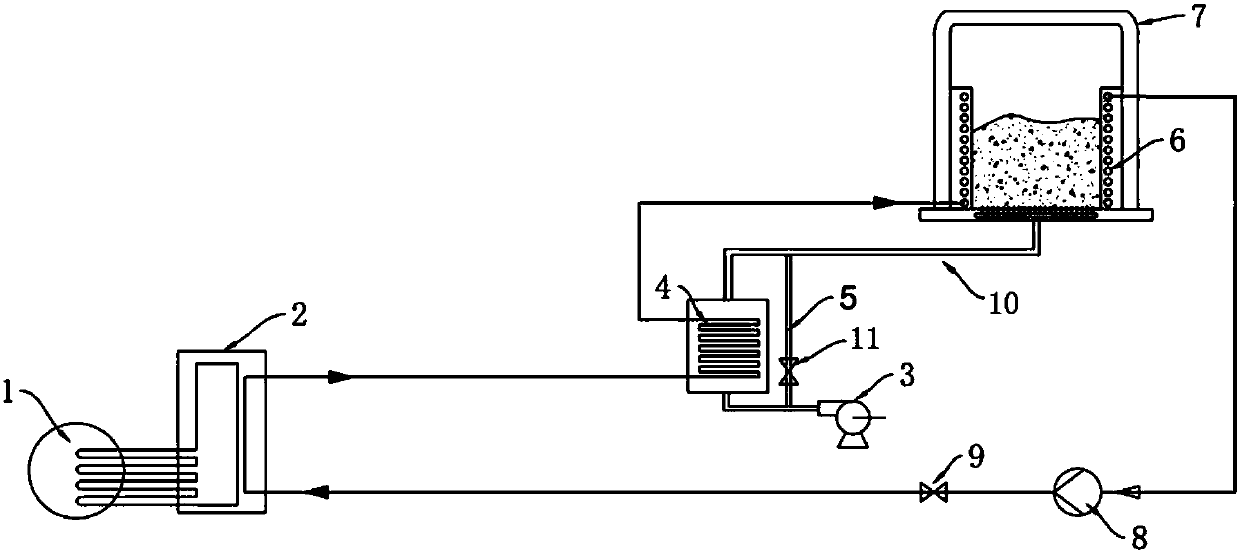

[0046] This preferred embodiment provides a system for recycling temperature and drainage of coastal power plants, the structure of which is as follows: figure 1 As shown, the system includes a heat pump 2, a hot water air heat exchanger 4, a heating buried pipe system 6 and an air supply subsystem: wherein,

[0047] The heat pump 2 is installed at the open cooling system of the condenser of the power plant; the heat medium water inlet of the evaporator is connected to the drain port of the temperature drain pipe 1 of the power plant, so that the evaporator absorbs the low-grade heat of the warm drain to gasify the circulating working medium , the cooled warm water is discharged from the heat medium water outlet of the evaporator; the refrigerant water inlet of the condenser is connected with the cold water outlet of the buried heating pipe system 6 to receive the medium water, so that the condenser can use the gasified circulating working fluid The heat released by liquefacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com