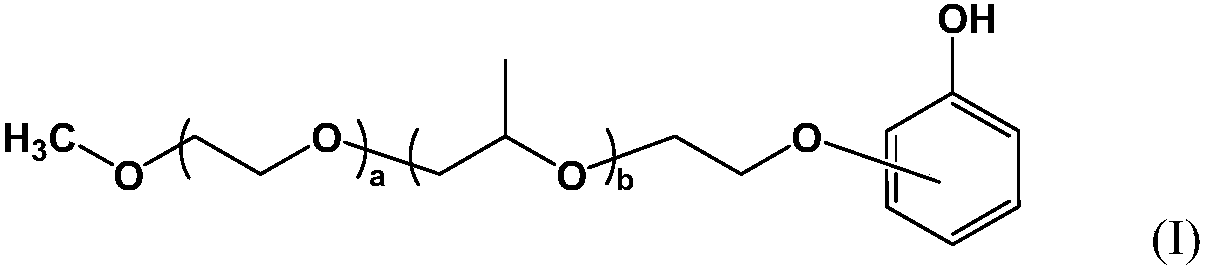

Methoxypolyether derivative, aminated polyether thereof, phosphorylated product thereof and preparation methods and application thereof

A technology of methoxy polyether and derivatives, which is applied in the field of methoxy polyether derivatives, can solve the problem of uncontrollable molecular structure and weight average molecular weight of water reducing agent, uncontrollable side reactions of copolymerization reaction, phosphorus-containing group It is prone to problems such as chain transfer, and achieves the effects of significant electrostatic repulsion, stable skeleton structure, and moderate water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

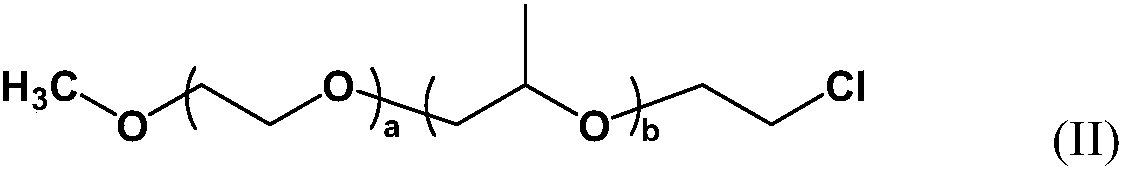

[0073] Preparation of Chlorinated Polyether M-1.

[0074] Weigh 1000 parts of methoxypolyether (M n =1000, a=22, b=0) into the reactor, under the condition of -0.08MPa~-0.1MPa, vacuumize for 1h to remove water and a little volatile components in the polyether. Cool down to 40~60℃, in N 2 Under protection conditions, add SOCl to the above reaction system 2 155 parts, the temperature of the reaction system is controlled not to exceed 60°C during the dropwise addition. After the dropwise addition is completed, connect the cooling reflux device, raise the temperature of the reaction system to 80-90°C, continue the heat preservation reaction for 3-5 hours, and then distill out the acidic volatile components in the reaction system under reduced pressure to obtain a light brown product, which is passed through Liquid phase test showed that the yield of chlorinated polyether M-1 was 98.5%. Other chlorinated polyethers in the present invention are prepared and tested according to ...

Embodiment 2

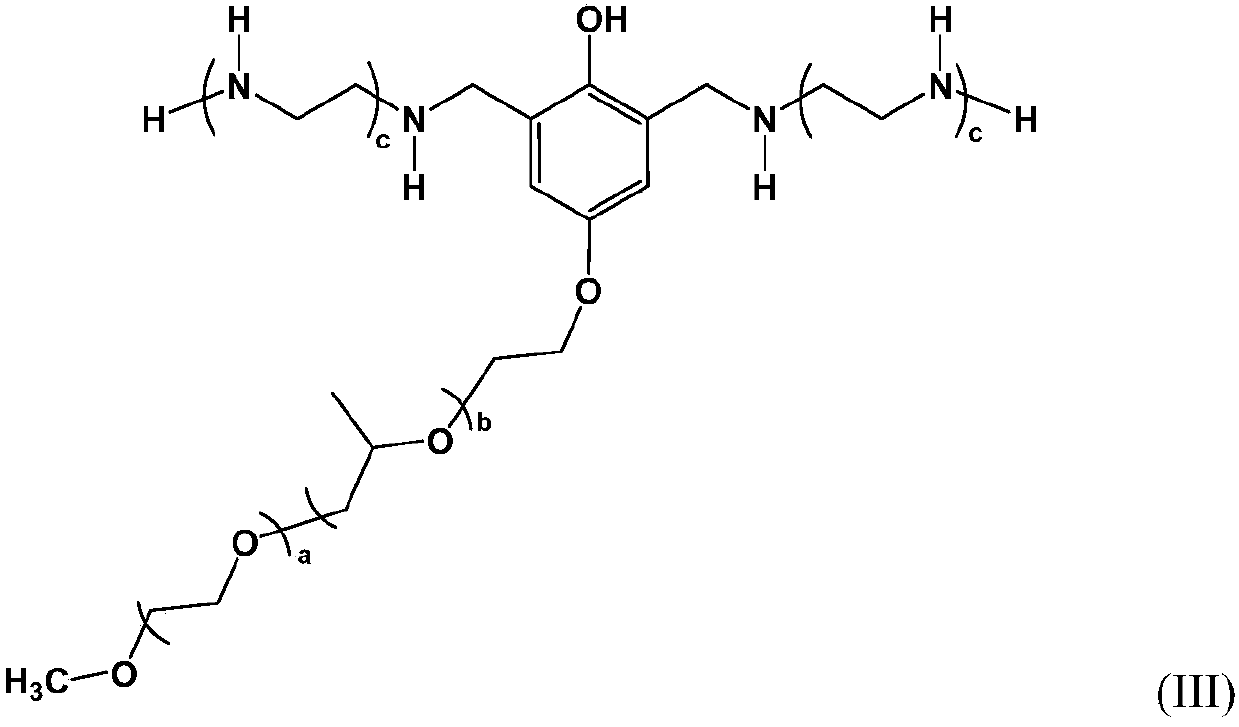

[0082]Preparation of Methoxypolyether Derivative N-1.

[0083] Weigh 242 parts of 30wt% NaOH solution as a primer, weigh 100 parts of hydroquinone, and gradually add the above reaction system, the color of the system gradually changes from colorless to light gray green, and the temperature of the reaction system is controlled to be less than 80 ° C during the addition process. After the dropwise addition was completed, it was kept at 60° C. for 0.5 h. Then gradually add 925 parts of M-1 to the reaction system. The reaction system has exothermic phenomenon. Control the temperature of the reaction system to about 70°C. After the addition is completed, transfer it to a closed high-pressure reactor, raise the temperature to 85°C, and keep it warm for 15 hours. After the reaction was finished, the consumption of NaOH in the reaction process was calculated by acid-base titration, and then converted into the yield of the methoxy polyether derivative. After titration conversion, the ...

Embodiment 3

[0091] Use N-1 as a base, add 422 parts of pentaethylenehexamine, stir evenly, then raise the temperature to 65°C, weigh 148 parts of 37wt% formaldehyde, add it dropwise within 2h, then raise the temperature to 70°C, and keep the temperature for 6h. Then gradually add 105 parts of 85wt% phosphoric acid to neutralize excess NaOH in the reaction system.

[0092] Cool in a water bath at room temperature, gradually add 422 parts of 36.5wt% concentrated hydrochloric acid to the above reaction system, then add 1193 parts of phosphorous acid, and finally gradually add 1179 parts of formaldehyde, connect the condensing reflux device, raise the temperature to 100 ° C, and keep the reaction time for 30 hours , to obtain a reddish-brown liquid, tested by GPC, with a weight-average molecular weight of 2801 and a PDI of 2.51.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com