Polythioamide as well as preparation method and application thereof

A polythioamide and polymerization reaction technology, applied in the field of polymer materials, can solve the problems of difficulty in synthesizing aromatic diacetylenes, reducing application value, etc., and achieve the effects of high yield, wide application range and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

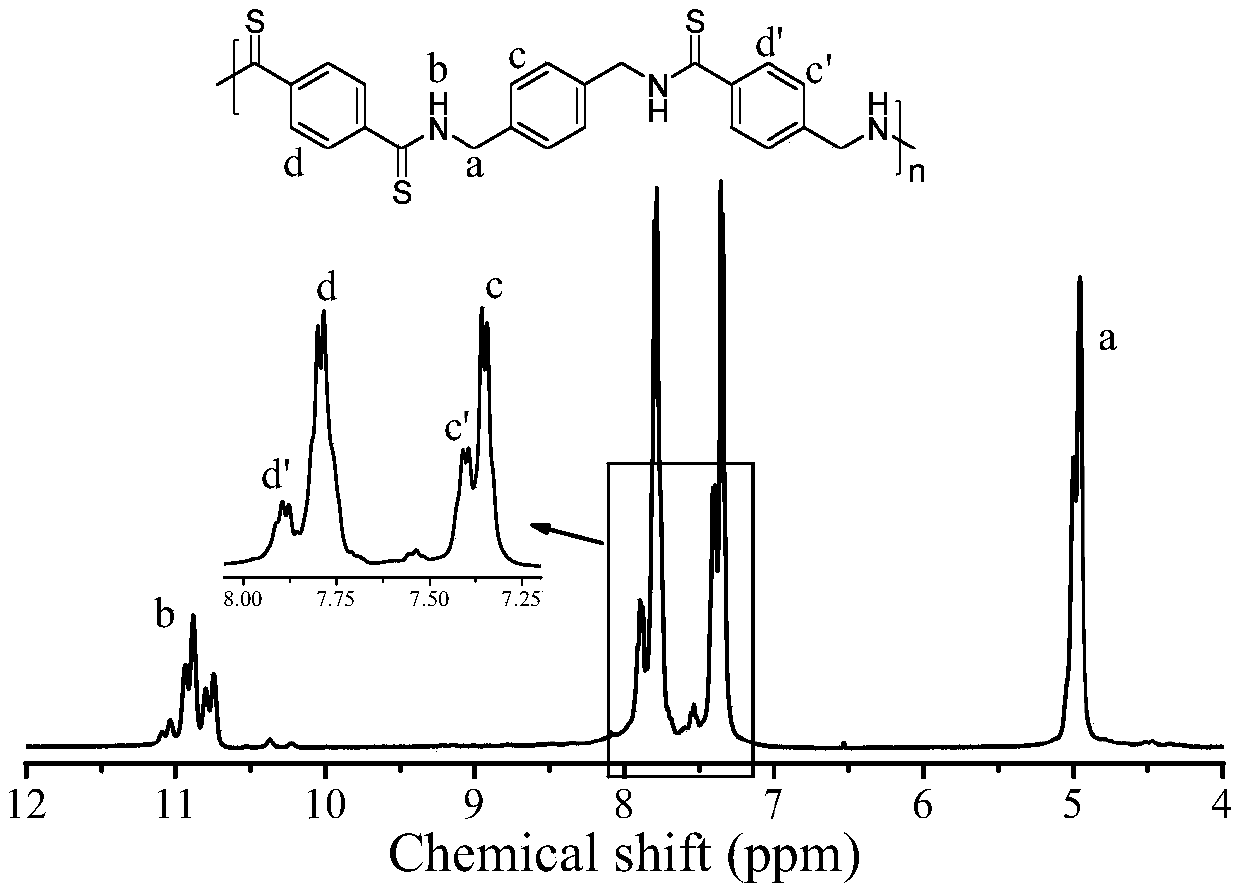

[0047] 1. In this embodiment, polythioamide is prepared by binary copolymerization of p-xylylenediamine and elemental sulfur, and the reaction equation is as follows:

[0048]

[0049] The concrete steps that present embodiment prepares polythioamide are as follows:

[0050] (1) Under the protection of an inert gas, dissolve 136.2 mg of p-xylylenediamine in 250 μL of N-methylpyrrolidone, then add 96.2 mg of sublimed sulfur, and raise the temperature to 110 ° C for 24 hours.

[0051] (2) After the reaction is completed and cooled to room temperature, the reaction solution is added to methanol for precipitation, and the precipitate is centrifuged and dissolved in dimethylformamide, and then precipitated in carbon disulfide again. After repeating twice, dry to constant weight in a vacuum oven to obtain the product polythioamide.

[0052] 2. Results

[0053] (1) The yield of the polythioamide prepared in this example was 83.8% by weighing method, and its weight-average molecu...

Embodiment 2

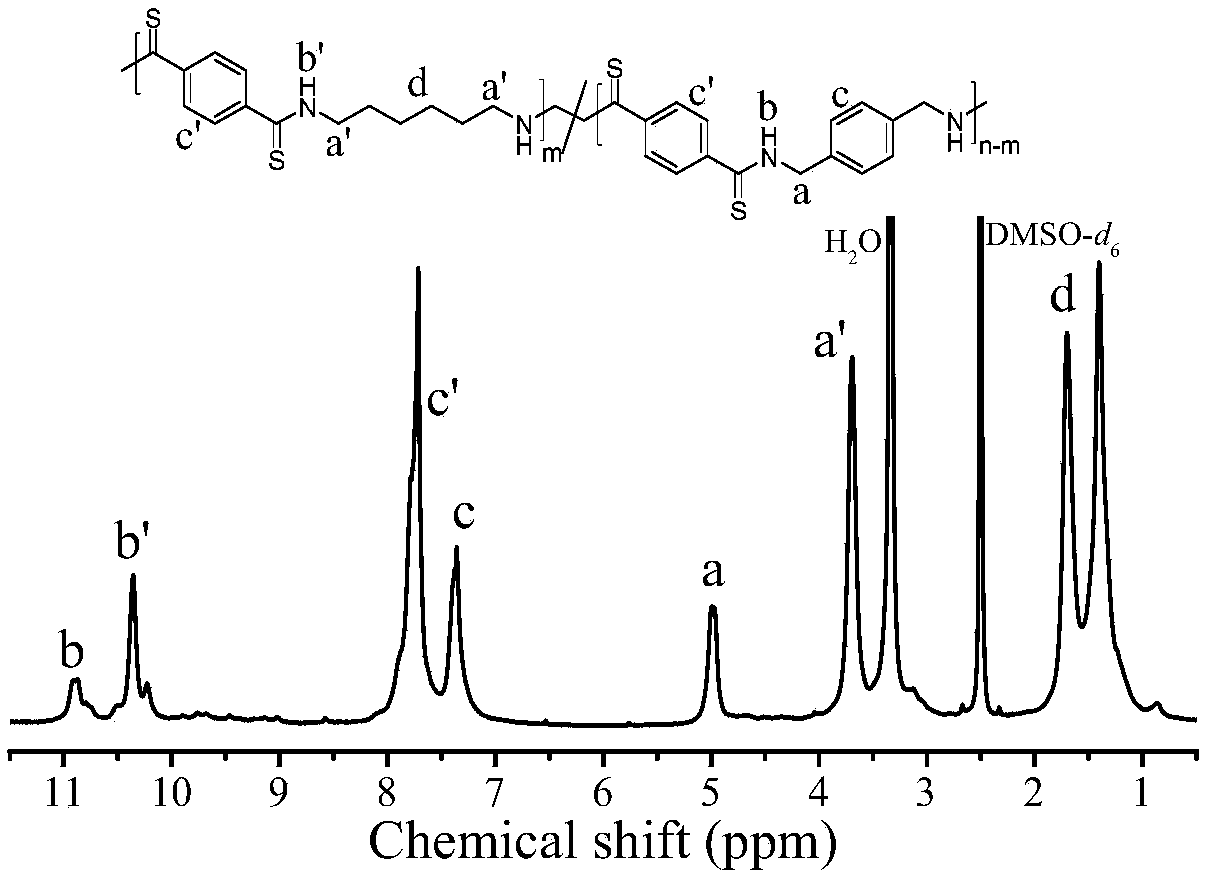

[0057] 1. In this example, polythioamide is prepared by ternary copolymerization of p-xylylenediamine, 1,6-hexamethylenediamine and elemental sulfur. The reaction equation is as follows:

[0058]

[0059] The concrete steps that present embodiment prepares polythioamide are as follows:

[0060] (1) Under the protection of an inert gas, dissolve 68.1mg of p-xylylenediamine and 58.1mg of 1,6-hexanediamine in 250µL of N-methylpyrrolidone, then add 96.2mg of sublimed sulfur, and raise the temperature to 110°C for 24 hours .

[0061] (2) After the reaction is completed and cooled to room temperature, the reaction solution is added to methanol for precipitation, and the precipitate is centrifuged and dissolved in dimethylformamide, and then precipitated in carbon disulfide again. After repeating twice, dry to constant weight in a vacuum oven to obtain the product polythioamide.

[0062] 2. Results

[0063] (1) The yield of the polythioamide prepared in this example was 43.8% b...

Embodiment 3

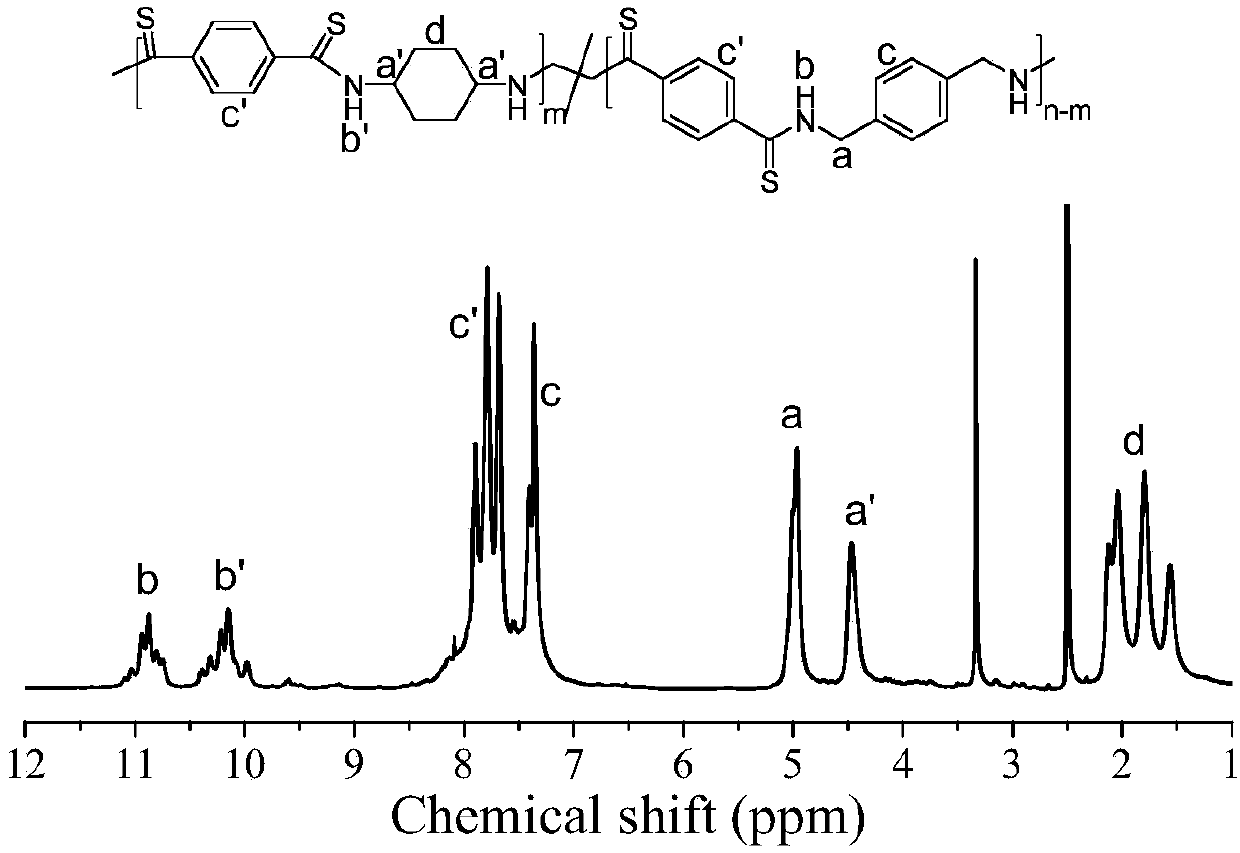

[0068] 1. In this example, polythioamide is prepared by ternary copolymerization of p-xylylenediamine, 1,4-cyclohexanediamine and elemental sulfur, wherein p-xylylenediamine and 1,4-cyclohexanediamine The feed ratio is 3:1, and the reaction equation is as follows:

[0069]

[0070] The concrete steps that present embodiment prepares polythioamide are as follows:

[0071] (1) Under the protection of an inert gas, dissolve 102.2mg of p-xylylenediamine and 28.6mg of 1,4-cyclohexanediamine in 250μL of N-methylpyrrolidone, then add 96.2mg of sublimed sulfur, and heat up to 110°C for 24 Hour.

[0072] (2) After the reaction is completed and cooled to room temperature, the reaction solution is added to methanol for precipitation, and the precipitate is centrifuged and dissolved in dimethylformamide, and then precipitated in carbon disulfide again. After repeating twice, dry to constant weight in a vacuum oven to obtain the product polythioamide.

[0073] 2. Results

[0074] (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com